Breaking (fiber plants)

The breaking of plant fibers is the central processing step in the extraction of bast fibers from the stems of annual fiber plants such as flax , hemp or also jute in a mechanical process. By breaking the epidermis layers and the lignified nuclei are broken open and crushed. The breaking is used with the subsequent steps such as panting to mechanically free the fibers of lignin and other plant debris.

Procedure

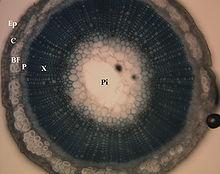

Stems of flax and other fiber plants are usually constructed in such a way that a hollow wooden core ( xylem ) is surrounded by fiber strands of the bast tissue . In order to be able to use the fibers, the wood must first be chopped up ( breaking ) and loosened and then removed ( panting ). Breaking is not aimed at breaking through the plant stems, as doing so would break the fibers; rather, it is a matter of breaking or squeezing the plant stem. It does this by placing a greater weight on the stems. In modern crushing processes, the stalks are processed with the help of rollers . The breaking takes place mechanically with a system of superimposed pairs of rollers which are equipped with teeth. The elastic cellulose fibers are not damaged in these mechanical processes if they run uniformly and the process is adequately adjusted to the material to be crushed.

Accompanying procedural steps

Breaking may be preceded by process steps such as fermentative treatment of the stems ( rotting ) and - in some cases combined with this - heat treatment by roasting . This dissolves the pectins that hold the fibers together in the stem. Following the breaking, the non-fiber parts are separated in vibrating turbines (swinging out). When panting, the raw fiber bundles are split into the finest fibers and these are cleaned. To do this, the shorter fibers are combed out in devices that are similar to carding machines . Another result of panting is a parallel arrangement of fibers, as is necessary for spinning.

Side processes

Depending on the type of plant, the amount of wood produced is considerable. For example, when breaking flax, 60% wood is produced in the form of shives , which suggests that it can be used as a raw material. Due to the fact that the shives are not well worth transporting, a spatial coupling with production processes that utilize the shives may even be an option.

Alternative procedures

Chemical methods (e.g. surfactant digestion ) and energetic methods (such as vapor pressure digestion ) are known as alternatives to the mechanical digestion of the stem fibers .

Historical proceedings

The wooden stalks used to be broken mechanically, originally by hand or a simple tool, the breaker . The lid of the breaker was moved up and down while the flax stalks are pulled further and further out of the breaker from the root ends to the tips. The wooden stem parts fall to the ground, the fibers remain in a tuft. In the process, however, the fiber was severely damaged and the yield of spinnable fiber was reduced. As early as 1880, breaking or bending machines were used to break the flax, in which the stalk was pushed between wooden or iron rollers with different depths and strengths.

Since not all of the wooden stem parts come off the fibers when they are broken, the next step was historically to swing the fibers. To do this, the broken stems were placed on a swing stick so that half of the fiber length was hanging down, and the so-called swing arm hit perpendicular to it, which stripped parts of the stems and shorter, unusable fibers out of the tufts.

yield

In the case of flax, according to the CMA, nine percent of the harvest weight is made up of so-called long fibers and seven percent is made up of Schwungwerg , i.e. short fibers. The respective proportion of long and short fibers obtained is, however, highly dependent on the one hand on the quality of the processed flax straw and on the other hand on the technical status of the processing methods. A ratio of 2/3 long fibers and 1/3 Schwungwerg can be achieved according to von Gleich with modern combinations of processes.

literature

- Arnim von Gleich: Flax cultivation and linen processing. EURES discussion paper 6 (1990) (pdf; 3.4 MB)

- Indra Ottich (ed.): A book of old fibers. 2nd expanded edition. 2006. (pdf; 3.52 MB)

Remarks

- ↑ cf. Deutsches Kolonial-Lexikon (1920), Volume II, p. 136.

- ↑ These upstream steps are not always necessary. If, for example, only coarser fiber material is to be obtained from hemp, for example for ropes, a purely mechanical breaking and panting without a previous roasting process ("green hemp") is sufficient.

- ^ Cf. Karl Häusler: Flax - a renewable raw material. In: teaching chemistry. 26 (1995) ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. (PDF; 325 kB), as well as from Gleich: Flax cultivation and linen processing. 1990, p. 30.

- ↑ Cf. von Gleich: Flax cultivation and linen processing. 1990, p. 54.

- ↑ Therefore, the stalks were tapped before actually breaking. For this purpose, the plant stalks were loosely held and beaten with a flat piece of wood (known in East Westphalia as a so-called bokeh chamber ). This increased the yield of long, usable flax fibers, since the fibers did not tear as quickly when the hand was then broken.

- ↑ Flax (processing). . In: Meyers Konversations-Lexikon . 4th edition. Volume 6, Verlag des Bibliographisches Institut, Leipzig / Vienna 1885–1892, p. 329.

- ↑ See A. von Gleich: Flax cultivation and linen processing. 1990, p. 31.