Rotary lobe pump

Rotary lobe pumps, also known as Roots pumps, are self-priming or partially self-priming, valveless , positive displacement pumps with two intermeshed rotary lobes. As pre-delivery blowers for downstream vacuum pumps , they are also manufactured with contactless rotors ( Roots blowers ). In particular, the incorrect designation as Roots compressor is misleading, as there is no internal compression , so that the principle is poorly suited for compressing gases or air. Nevertheless, it is occasionally used as a pragmatic technique for supercharging the engine , whereby the Roots blower works technically as a compressor , but with a very poor efficiency ; the efficiency drops sharply with increasing pressure difference above about 1 bar, because when the non-compressing air chambers are opened on the pressure side, already compressed gas hits back and thus destroys the work applied against the pressure in flow losses.

Function and structure

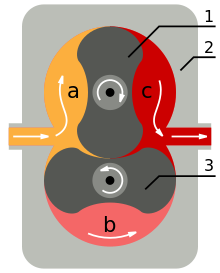

The rotation of the pair of rotors (1, 3) creates a negative pressure on the suction side (a), which can be determined by the direction of rotation of the drive, as a result of which the pumped medium is sucked in. The pumped medium then passes through the rotors (b), past the pump wall (2) and into the pressure area (c). With one drive revolution - depending on the type of rotors, whether they have two or more blades - two to six room fillings are displaced. When the rotor pair comes to a standstill, the pump closes almost completely. This applies to rubberized rotors. If the rotary lobes are made of steel or stainless steel, they are undersized to prevent seizure. A complete seal is therefore no longer possible with these.

Safety chamber ( quench )

Some rotary lobe pumps have an intermediate chamber between the pump housing and the gear housing. This is filled with a liquid that fulfills several tasks:

- It acts as a safety chamber for the mechanical seal, indicates leaks in the mechanical seal due to overflow at the filling opening and lubricates the connection between shafts and rotors.

- It prevents the pumped medium from penetrating the synchronized gear unit.

- In addition, a quench medium protects against dry running.

variants

In addition to the straight pistons in the pump chamber, there are also versions with coiled, contact-free rotors (so-called helical pistons), with the triangular or trapezoidal chamber openings forming exact sealing lines to the coiled rotors. This variant reduces the pulsation of the pump and the pumped medium is less destroyed. The pistons can also be coated with rubber . This results in a self-priming pump, which, however, generates abrasion. This can lead to contamination of the medium with piston abrasion.

The rotor can be equipped with claws; this results in a higher compression with a more uneven discharge (claw pump). The starting torque of rotary lobe pumps depends on their design: whether the rotary lobes touch each other, are in contact with the housing wall or not.

In order to achieve even better product protection, there are also sinusoidally wound rotor pairs.

The cavity can also be created between three co-rotating rotors, which results in an axial ejection.

Funding area

A rotary lobe pump delivers volume flows of around 1–1500 m³ / h, depending on the viscosity of the medium. Claw pumps are available up to 300 m³ / h.

Properties of rotary lobe pumps

- Rotary lobe pumps are also suitable for media with high sediment content and work reliably even with fluctuating solid content.

- Different solids contents do not affect the delivery rate and the fluctuations in the amount of pressure changes caused by the amount of solids are small.

- Because of their large free ball passage and the low pump speeds, they are relatively insensitive to clogging, clogging and foreign bodies.

- The rotary lobe pump is self-priming or partially self-priming and its usually symmetrical design allows the direction of rotation and thus the direction of delivery to be reversed - an advantage that is particularly useful for emptying solids collectors.

- A rotary lobe pump can convey both low and high viscosity media. As a result, they can be used in the sugar industry for drainage or molasses as well as corn root or magma (mixture of granulated sugar and syrup). This reduces the costs for stocking spare parts as well as the training effort.

- The efficiency of positive displacement pumps is higher than that of many other positive displacement pumps. This results in lower energy consumption than, for example, flap pumps and saves investment costs for drives and controls (such as frequency converters). Since energy accounts for the largest share of the life cycle costs of a pump, this advantage is an essential criterion when selecting the type of pump.

- Rotary lobe pumps are compact. The suction and pressure connections are in one line.

- The system consisting of a three-phase asynchronous motor and rotary lobe pump has a flat pressure-volume characteristic: if the delivery pressure increases, the volume flow decreases only insignificantly, while the power consumption increases. With centrifugal pumps, on the other hand, the volume flow drops rapidly with increasing delivery pressures.

- Many types of rotary lobe pumps work without internal compression in contrast to vane pumps, for example. The isentropic efficiency is lower than with internal compression .

Rotary lobe pump (Roots pump)

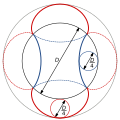

with coiled rotary lobe ( helical gearing )The contour of the runner is composed of rolling curves : epicycloids (red, outside) and astroids (blue, inside)

See also

literature

- WH Faragallah, D. Surek : Rotating displacement machines , 2nd, revised. Edition. Faragallah, Sulzbach 2004, ISBN 3-929682-36-2

- K.-H. Grote, J. Feldhusen: Dubbel, pocket book for mechanical engineering . 22., rework. u. exp. Edition. Springer Verlag, Berlin 2007, ISBN 978-3-540-49714-1

Web links

Individual evidence

- ↑ sites.google.com

- ↑ Busch pressure / vacuum claw pumps

- ↑ herold-gefrees.de