Electron gun

An electrical arrangement for generating electron beams is referred to as an electron gun , also known as an electron beam system , electron source or beam system for short . The electron gun provides a focused and directed electron beam, as is used, for example, in electron tubes and electron microscopes , as well as in electron beam melting as a beam system. In the case of general electron sources, there is no concentration of the electron beam.

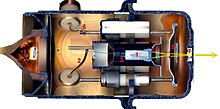

In the construction are electrons of an electric conductor - the cathode , which is usually heated to the work function for the charge carriers to ensure - in a vacuum emitted. The positive voltage at the anode compared to the cathode accelerates the electrons towards the anode. In the anode of electron guns, there is a hole through which the electron beam can pass.

principle

➀ Hot cathode

➁ Wehnelt cylinder

➂ Anode screen

In most designs, the electrons are emitted from a suitable cathode and accelerated to an anode by a constant electrical potential difference (the acceleration voltage U B ) . The kinetic energy E k of an accelerated electron is approximately

Where e is the elementary electrical charge . The definition of the energy unit electron volt (eV) results from this relationship . If a material sample is placed in the path of the beam, the energy of the electrons determines their range in the material. It is therefore an important parameter for many technological applications.

If N is the number of electrons that pass through an imaginary surface perpendicular to the beam in time t (e.g. one second), then is

the electric current of the electron beam (beam current), the technical direction of which points to the cathode. In addition to the kinetic energy, the beam current is a measure of the impact on impact, for example the heating of the material (e.g. during welding) or the brightness of a screen. Further technology-relevant parameters are the beam power (product of beam current and acceleration voltage) and the power density , which results from the beam diameter and the beam power.

The beam often leaves the cannon through a hole in the anode, the size of which also determines the beam diameter. Additional, often ring or tubular electrodes as well as magnetic fields within the scope of electron optics ensure the focusing or further acceleration of the electron beam. They can be attached both between the cathode and anode, as well as after the anode. Accordingly, one speaks of electrostatic or magnetic focusing. Axially symmetrical magnetic fields are used for magnetic focusing.

The electron beam can be deflected by a deflection system , i.e. H. be deflected from its direction by transverse electric or magnetic fields in order to allow it to hit a certain location.

Space charge

The above relationship between E k and U b applies exactly only to electrons on the surface of the beam or to a very low beam current. Electrons that are further inside the beam are accelerated less strongly because the electric field of the electrons further outside partially shields them from the acceleration voltage, which is known as the space charge effect.

If the acceleration voltage is too low to suck up all emitted electrons quickly enough, they gradually form a space charge cloud in front of the cathode, the electrical potential of which reduces the emission of further electrons (space-charge-limited operation). This may well be desired so that, for. B. the electron current remains constant at a fixed acceleration voltage even if the perveance of the cathode (the maximum rate of electron emission) z. B. changed by temperature change or aging of the cathode. Under these circumstances, the dependence of the beam current on the accelerating voltage will be described.

The beam current can be controlled with a Wehnelt cylinder which delimits the space charge zone of the cathode and is at a negative potential with respect to the cathode. It is a control grid for focusing of electron beams and for controlling the brightness in cathode ray tubes . The otherwise necessary very high anode voltage can be reduced by using the Wehnelt cylinder .

technical realization

All parts of an electron gun are in high vacuum in order to increase the mean free path of the electrons to distances of the order of magnitude of the structure. The electrons present in the cathode material are usually released through one of the following three processes:

- Glow emission ( Edison effect )

- Field emission

- Photoemission (external photoelectric effect ).

Mostly hot cathodes are used as electron emitters. In the picture, the heating element (number 1 in the picture) is connected to the external heating voltage source via the supply lines (2) and (3) (external contact not visible).

In the case of completely space charge-limited operation of the cathode, the beam expansion caused by the space charge can be compensated to a good approximation by using a so-called pierce shield. This is an electrode with a conical opening (67.5 ° opening angle) within which the cathode is located. For electron beam systems that are operated with a high acceleration voltage, the cathode is often enclosed by a Wehnelt cylinder. The accelerated jet emerges from this through a small hole on the front side. The Wehnelt cylinder allows the beam current to be controlled with almost no power, as it is usually negative in relation to the cathode and therefore does not carry any current itself.

Wehnelt cylinders with Pierce diaphragm (4) are arranged around or to the right of the heat source. The red lines indicate the Pierce angle between the electron beam (yellow lines) and the Pierce diaphragm. The anode (5) and the high-voltage lead accelerate the electron beam.

The electron beam usually remains (for example in picture tubes or traveling wave tubes ) in a vacuum, but can pass through aerodynamic windows or windows, e.g. B. leak from thin aluminum from the vacuum. In air it has a range of up to a few centimeters corresponding to its acceleration voltage. In the picture, the electron beam enters the right part of the traveling wave tube (not shown here) through the diaphragm (7).

Electron guns are used with beam powers of a few n W (small experimental systems), a few watts (microsystem applications, picture tubes ) up to a few hundred kilowatts ( electron beam melting , electron beam evaporation ). Acceleration voltages are between a few V and approx. 300 kV , depending on the application . The beam diameter is between a few micrometers and a few centimeters, depending on the application . The power densities reach values of up to 10 7 W / cm 2 .

Types of cathodes in electron microscopes

Various types of cathodes, called filaments, are used in electron microscopes:

Hairpin cathode

Many devices have a hot cathode (also called filament) made of a tungsten alloy . These cathodes - also known as hairpin cathodes because of their shape - are inexpensive, easy to use and deliver a high beam current, which z. B. is necessary for WDX and EDX analyzes. A disadvantage of the hairpin cathode is that it does not allow a point electron source, which also limits the resolution. Furthermore, this electron source is maintenance-intensive, since the filament becomes thinner and thinner with use and ultimately burns through and has to be replaced. The service life of a filament is between 100 and 500 hours.

In addition, tip cathodes with a welded-on tungsten tip are also offered. The front tip radius is only a few micrometers . As a result, the emission of electrons is concentrated on a smaller cross section and provides a more coherent beam with higher overall brightness. The tip cathodes require an extremely good vacuum, because otherwise the service life will be reduced to just a few hours by sputtering processes.

LaB 6 cathodes and CeB 6 cathodes

Single crystal lanthanum hexaboride - or Ceriumhexaborid cathodes (LaB 6 , CeB 6 ) consist of tiny peaks, which sit on a support. Lanthanum hexaboride and cerium hexaboride have a very low electron work function. In the scanning electron microscope, the luminance obtained in this way leads to a better image resolution and to a better signal-to-noise ratio compared to the tungsten cathode. In micro-analytical applications (EDX), a smaller beam diameter and better counting statistics are achieved. The service life of up to 3000 hours is longer compared to the tungsten cathode, but requires a vacuum in the cathode compartment of 10 −5 Pascal or better. In addition, the cathode must be carefully handled, centered and heated / cooled.

Field emission cathode

In modern electron microscopes, field emission cathodes (FEM) are used for the highest resolutions. In the cold field emission cathode (field emitter), electrons are drawn out of a fine monocrystalline needle tip exclusively by high voltage and accelerated towards the anode. The advantage of this "cold cathode" is a very thin primary beam, the disadvantage is the relatively low beam current.

Since the early nineties, are becoming more common field emission scanning electron microscopes ( FESEM of English Field Emission Scanning Electron Microscope ) and transmission electron microscopes with Schottky found -Feldemissionskathode. This technology, also known as warm field emission, represents a sensible compromise between high electron yield from a hot cathode and the fineness of the electron beam from the field emission cathode. The result is a universally applicable electron microscope that has both very high resolutions and very good analytical capabilities. With this type of cathode, the parameters of the electron beam are constant over long periods of time, which is of great benefit to the quality of long-term studies. One disadvantage is the relatively high price, which is compensated for by the long service life of at least one to seven years.

Applications

Electron beam systems are used both in research (as electron injectors for accelerators ( betatron )) and in industry ( electron beam welding , hardening , perforating, radiation crosslinking , sterilization , electron beam lithography , electron beam balancing ).

A well-known technical application of electron beam systems is the Braun tube ( cathode ray tube ( oscillograph tubes , tube monitors , television sets with picture tubes)). Also, X-ray tubes using electron beams.

Electron beams are also used for electron microscopy and in time-of- flight tubes (traveling wave tube, gyrotron ).

X-rays

When they hit metal surfaces, electrons generate braking X-rays . This effect is used in X-ray tubes to generate X-rays, but it is undesirable in most other electron beam systems. The hardness (quantum energy or reciprocal of the wavelength) of the X-ray radiation increases with increasing acceleration voltage, its intensity increases with increasing density of the target and the beam current. Harder X-rays, such as those that occur with high acceleration voltages, are able to penetrate the wall of the vacuum apparatus and can cause radiation damage. It must then be shielded.

The emission of X-rays also occurs with other electron tubes with high anode voltage. It is one reason why the acceleration voltage of picture tubes is limited to about 27 kilovolts.

Web links

- Simple simulation of an electron gun (LMU Munich)

Individual evidence

- ↑ a b Plano GmbH: Cathodes and diaphragms ( Memento of the original from March 4, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 3.1 MB)