Friction gears

The friction gear or faceplate friction gear is a simple variant of the rolling element gear . It does not correspond to the friction drive , even if the English expression friction drive suggests it.

functionality

The friction consists of a drive shaft with a non-positively connected with it, thus driving rotation - the body (referred to plan or friction disc), (friction or a body to be driven friction wheel called) and a driven shaft. The friction wheel is also positively connected to its shaft.

The driving body is rotated by a power source with the speed of its shaft. The driven shaft is attached in such a way that the friction wheel rests or rolls on the surface of the friction disk. As a result, it absorbs power and passes it on to the driven shaft. In contrast to the similar friction gear , the axes of the two wheels are not parallel , but at an angle to each other. The friction wheel has a coated running surface or a tire to improve the grip (“grip”) on the friction disk.

The translation of the friction gear varies depending on the point on the friction disc where the friction wheel is attached; the closer to their center this happens, the slower the friction wheel runs. This fact can be used to change the speed of the driven shaft at a constant speed of the drive. The friction wheel can be moved on its shaft by means of a lever and tensioning device, which changes the amount of friction. This results in a continuously adjustable power transmission.

Another influencing factor is the adjustable contact pressure of the friction wheel on the disc. This is achieved by shifting the driven shaft, which requires little leeway. If the shaft is pushed away from the friction disc, the power transmission is interrupted and the gearbox is disengaged, so to speak. By pressing against the friction disc, the slip between the friction disc and wheel is reduced , so efficiency is improved. However, this also increases loads on the motor, friction disc and wheel, as well as on the shaft itself and its bearings.

Advantages and disadvantages

In addition to the infinitely variable power transmission mentioned, friction gears have other advantages. Compared to other gearboxes, they are relatively easy to manufacture. Their construction is simple and has few moving parts, resulting in less weight, simple operation, less wear and tear (typically tires or coating of the friction wheel) and also less maintenance. In addition, overloading only causes the friction wheel to "slip" on the disc, which usually does not result in any consequential damage.

The disadvantages include the suitability of the gearbox only for low-power or low-torque drives and the excessive slip , which significantly worsens the efficiency . This can be counteracted at least partially by an adjustable contact pressure - for example by moving the friction wheel shaft - but at the cost of a higher bearing load. Conversely, analogous to a conventional clutch , the frictional connection between the flywheel and the friction wheel can be separated by removing the contact with the flywheel by pushing the friction wheel shaft away.

Application in the automobile

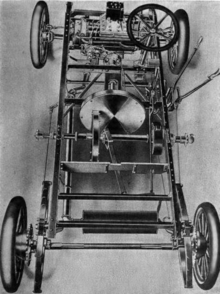

The friction transmission found a popular application in light automobiles with front or rear engines in connection with rear drive . These transmissions were most widespread between around 1895 and 1920. Front- wheel drive applications are not known.

To save material and weight, the flywheel of the engine was often designed in such a way that it could also take over the function of the friction disk. With this form of power transmission, the friction wheel rolls directly on the flywheel.

Mostly, belt pulleys are attached to one or both ends of the driven shaft , which guide the rotary movement to the rear axle via belts or chains.

At the beginning of motorization, friction gears were simpler and easier to operate than the already known manual transmissions. The narrow technical limits and the emergence of better gearboxes - especially with the planetary gearbox of the Ford Model T - made the friction gearbox a niche application in the automotive sector. It was more or less widespread recently in highwheelers and cycle cars . Highwheelers disappeared around 1912, while cyclecars and other small automobiles lasted significantly longer, albeit not in widespread use.

Additional disadvantages were the limited climbing ability of such vehicles on the mountain and that “rocking free” out of snow or soft ground was hardly possible due to the construction. After all, was still in 1913 one of the toughest background checks for automobiles, the Glidden Tour , from Metz Model 22 won a two-cylinder - Voiturette with friction.

Automobiles with friction gears (selection)

- Aero

- Brush

- Cartercar

- Ceco

- Continental

- Grade

- Imp

- Lambert

- Masons Union

- Metz

- Orient and Waltham-Orient

- Petrel

- Sears

- Simplicity

- Simplo highwheeler

- titanium

- Turicum

- Twombly

- union

swell

literature

- Beverly Rae Kimes (Editor), Henry Austin Clark Jr.: Standard Catalog of American Cars 1805–1942. 2nd Edition. Krause Publications, Iola WI (1985), ISBN 0-87341-111-0 . (English)

- Beverly Rae Kimes: Pioneers, Engineers, and Scoundrels: The Dawn of the Automobile in America. Published by SAE (Society of Automotive Engineers) Permissions, Warrendale PA 2005, ISBN 0-7680-1431-X . (English)

- James J. Flink: America Adopts the Automobile - 1895-1910 , MIT (Massachusetts Institute of Technology), 1970. ISBN 0-262-06036-1 . (English)

Individual evidence

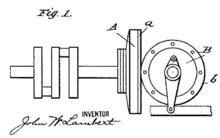

- ↑ Patent US761384 : Friction-gearing. Registered July 19, 1902 , published May 31, 1904 , Applicant: Buckeye Manufacturing Company , Inventor: John W. Lambert.

- ↑ Patent US954977 : Friction driving mechanism. Registered January 7, 1909 , published April 12, 1910 , inventor: John W. Lambert.

Web links

- Screw gear with automatic pressure regulation / friction gear. In: Polytechnisches Journal . 325, 1910, pp. 326-329.