GB C 4/5

| GB C 4/5 | |

|---|---|

| Numbering: | 2801-2808 |

| Number: | 8th |

| Manufacturer: | Maffei |

| Year of construction (s): | 1906 |

| Retirement: | 1925 |

| Type : | 1'D h4v |

| Gauge : | 1435 mm ( standard gauge ) |

| Length over buffers: | 16802 mm |

| Fixed wheelbase: | 3300 mm |

| Total wheelbase: | 7500 mm |

| Empty mass: | 71.0 t |

| Service mass: | 76.7 t |

| Service mass with tender: | 115.28 t |

| Friction mass: | 62.4 t |

| Wheel set mass : | up to 15.6 t |

| Top speed: | 65 km / h |

| Indexed performance : | 1500 hp |

| Starting tractive effort: | 10900 kp |

| Driving wheel diameter: | 1350 mm |

| Number of cylinders: | 4th |

| HD cylinder diameter: | 395 mm |

| LP cylinder diameter: | 635 mm |

| Piston stroke: | 640 mm |

| Boiler overpressure: | 15 atm |

| Grate area: | 4.07 m² |

| Tender: | 3-axis |

| Water supply: | 17 m³ |

| Brake: | Double Westinghouse brake |

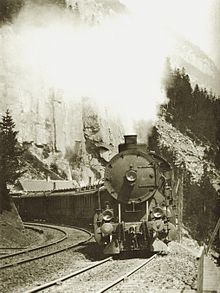

The C 4/5 were Heissdampf- Verbund - Tender locomotives of the Gotthard Railway Company (GB), which were delivered by Maffei in 1908 . They already received SBB numbers 2801–2808 from the GB .

prehistory

Since 1897, the Gotthard Railway has been using four-cylinder compound locomotives of the A 3/5 series for the transportation of express and express trains , which run through the entire Lucerne - Chiasso line with their different gradients . These locomotives with a top speed of 90 km / h drove express trains with a trailer load of 320 tons at a speed of 60 km / h on the valley lines . On the mountain routes with a gradient of 27 ‰, they carried 140 tons of car weight at 40 km / h. With a second A 3/5 as a pre-tensioning locomotive, a train load of 280 tonnes was mastered on the mountain routes, while at that time the maximum permitted drawbar load was 320 tonnes.

With the increasing use of heavy four-axle passenger coaches , the trains often became so heavy that the A 3/5 was no longer sufficient as a leader and a third machine had to be pushed in. The GB therefore ordered eight Consolidation- type pre-tensioning machines from JA Maffei in Munich , which, together with an A 3/5 express trains , could carry up to 320 t of trailer load at a speed of 40 km / h without pushing . The machines had to reach a speed of 65 km / h on the valley railway lines.

technology

The C 4/5 rested on a front running axle and had four coupled axles , of which the second was the drive axle , on which all four cylinders acted. The large boiler with 15 atm working pressure was given a high position because of the large, wide grate that was mounted above the frame and the rear drive wheels. Its center was 2870 mm above the top of the rail. The long boiler with an average diameter of 1780 mm had a two-part welded steam dome and two pop safety valves . A clench steam dryer was built into the long boiler under the steam dome . The fire box with a grate area of 4.07 m² was attached to the outer fire box in the usual way with stud bolts . To prevent sparks from being thrown, a spark grid made of iron wire mesh was installed in the smoke chamber .

The steam extraction for the injectors , the manometer , the air pump of the Westinghouse brake and the steam heating were carried out on the outer rear wall of the fire box. Because of the high position of the boiler, the steam whistle could not be mounted on the roof of the driver's cab as usual , but had to be attached to the ceiling of the outer fire box. Two Friedmann injectors were installed in the driver's cab to feed the boiler ; which always fed the amount of water into the boiler during the ascent that corresponded to the respective boiler output.

The forged bar frame gave the locomotive an elegant look. Compared to the previously used sheet metal frame, it offered the advantages of a better overview and easier accessibility for the internal engine parts of the machine. Thanks to the lower weight of the bar frame, the boiler could be built larger and more powerful. The first three coupled axles were firmly mounted in the frame, while the rearmost coupling axle had 10 mm of lateral play on both sides. To make it easier to drive through the curves, the flange thickness of the drive axle was reduced by 5 mm. The front barrel axle was designed as an Adam axle and was returned to the central position by a double leaf spring . The suspension of all axles was carried out by leaf springs, which were arranged below the axle bushes for the coupled axles and above the barrel axle. The suspension springs of the barrel axle and the two front coupled axles as well as those of the two rear coupling axles were connected to one another by compensating levers.

The four cylinders of the engine were all side by side behind the barrel axis and under the smoke chamber. The two high-pressure cylinders were arranged within the frame and, together with the piston valve housings, were cast in one piece, which was screwed tightly to the smoke chamber at the top. The whole casting also formed a strong frame reinforcement. The low-pressure cylinders arranged outside the frame were screwed to the high-pressure cylinders. All four cylinders had piston valves . The high-pressure piston valves had a single internal flow, while the low-pressure piston valves were designed with double flow in and out to avoid pressure losses. A start-up device enabled the low-pressure cylinders to be fed with live steam. The steam distribution in the high and low pressure cylinders was carried out by a joint external Heusinger control , which drove the low pressure slide in the usual way, while the high pressure slide was moved by a transmission shaft. The high-pressure and the low-pressure cranks were offset from each other by 90 °; the right pair of cranks was ahead of the left by 90 °.

The locomotive was equipped with the Westinghouse double brake. The automatic brake acted on the wheels of the four coupled axles on one side and on all tender wheels on both sides. The regulating brake, on the other hand, only acted on the tender wheels, which could also be braked with a spindle brake.

The locomotives were equipped with a Klose speedometer, an air sand spreader according to the Leach system, another sand spreader operated by hand pull and with steam heating . The piston valves and the steam pistons were lubricated on each side of the locomotive with a Friedmann lubricating pump.

The three-axle tender corresponded to that of the A 3/5 931-938 and had an external sheet metal frame. The water tank, which was built in the shape of a horseshoe at the top, was pulled through below and between the frame sheets under the space intended for the fuel. The locomotive and tender were connected by a strong screw coupling and two note irons.

1913-1916 the Clench steam dryer were Schmidt - superheater replaced.

Operational use and replica

When they were delivered in 1906, the C 4/5 were given SBB numbers 2801–2808. When the Gotthard Railway Company was nationalized in 1909, the eight locomotives came to the Federal Railways. The powerful machines met the requirements and proved themselves as pre-tensioning locomotives. They carried heavy express trains as well as freight trains on the longer mountain ramps at the remarkable speed of 40 km / h. Due to the advancing electrification, the small series of locomotives was retired in 1925.

When the Royal Bavarian State Railroad procured further 1'D locomotives in 1915 , they had the reliable C 4/5 of the Gotthard Railway largely rebuilt and added them to their inventory as the G 4/5 H. At the time of the Reichsbahn , the locomotive was represented throughout Germany with 230 copies and was one of the most reliable, economical and powerful machines of this type.

literature

- The four-cylinder compound locomotive with four coupled axles, Series 4/5, of the Gotthard Railway. (PDF 5.4 MB) Schweizerische Bauzeitung, Volume 50 (1907), Issue 19, pp. 235–240 , accessed on May 1, 2014 .

- Carl Waldis: Welcome to the Gotthard Railway. The Gotthard Railway's steam locomotives. Retrieved May 1, 2014 .