Pit bar scale

| Bar scale | |||

|---|---|---|---|

| General information about the mine | |||

| Engraving of the pit bar scale around 1856 | |||

| Mining technology | Civil engineering , roof construction | ||

| Rare minerals | Coesite , Covellin , Malachite , Chrysocolla | ||

| Information about the mining company | |||

| Employees | at least 38 | ||

| Start of operation | 1751 | ||

| End of operation | 1928 | ||

| Successor use | farm | ||

| Funded raw materials | |||

| Degradation of | Iron ore , copper | ||

| Greatest depth | at least 150 m | ||

| Geographical location | |||

| Coordinates | 50 ° 43 '36.7 " N , 8 ° 13' 7.8" E | ||

|

|||

| Location | Donsbach | ||

| local community | Dillenburg | ||

| country | State of Hesse | ||

| Country | Germany | ||

| District | Dillenburg mountain area | ||

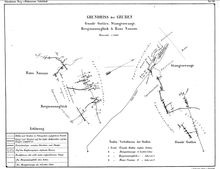

The pit bar scale (also bar scale ) was an iron ore and copper mine near Donsbach (municipality of Dillenburg ) in the Lahn-Dill district . The pit lay between Langenaubach , Haiger and Donsbach.

Aisle means

The gangway was within a band made of Schalstein, which stretched from above Donsbach via Nanzenbach to Hirzenhain . The most famous pits on this gangway were:

- Old hope near Langenaubach

- Bar scales, the luck of the miners , God's grace near Donsbach

- Rose garden at Sechshelden

- Nicolaus and Fortunatus near Dillenburg

- Alte Lohrbach, Neuermuth, common colliery near Nanzenbach

The pit was built on several gangways.

- Schliechgang (name comes from the fine-grained ore species): spathy, first medium with 12 m length and thickness of 0.5–1 feet, reached via a crosscut from the deep tunnel; second means 30 m in length, thickness up to 2 feet (on a short distance even up to 2 m), in the 8th to. 10 hour painting and southwest. dipping at 50–60 degrees, 80 m from the first mean

- Brown or hanging passage: quartz, noble on several meters, stroking in the 9th to 12th hour and 72% west or south-west. Dipping at 50–60 degrees, identical to the 8th gear of the Bergmannsglück mine , wedges 150 m depth

- Weather flutter: noble at 30–32 m

- Ländches passage: weak, quartz, consisting of kidney whites and copper liver ore, was reached over 120 m long cross passage of the deep tunnel, in 10–11. Hour stroking with southwest. 70 degree dip

- New course: in the 9th hour stroking and southwest. incident at 70–75 degrees

Some of the corridors were up to 3 m thick and up to 40 m long.

history

The first mining activities in the area of the Stangenwage mine probably go back to the 16th century. In 1751 the deposit was discovered in a shaft in which iron stone was supposed to be mined. In 1752 the mine was not yet fully unionized. In 1758 ore from the mine in Dillenburg's Isabellenhütte is melted for the first time . In 1771, one florin yield was achieved per kux (pit portion).

Around 1789 there was an upper and an approx. 500 m long, deep tunnel through which the ore material was reached after approx. 280 m. After a length of approx. 340 m, the deep tunnel met a weather shaft . This tunnel, known as the deep tunnel in 1789, became the middle tunnel after the construction of an even deeper tunnel (before 1831). In 1856 a civil engineering shaft was created. There was a 5–6 foot thick Roteisenstein deposit consisting of calcareous, but rich ironstone, which in 1867 was exposed to the second Gezeugs section (120 m deep). In 1867 the upper tunnel was 520 m long, the deep one above the village at 334.79 m above sea level and reaching a depth of 70 m at the machine shaft was approx. 1 km long.

Mining and Hütten-Aktiengesellschaft Oranien in Dortmund acquired the mine around 1857, along with a further 18 copper ore and 7 iron stone pits around Dillenburg, 60 iron stone pits around Siegen and 5 hard coal fields near Dortmund. In 1857, red iron stone ore worth 30,000 guilders was sold from the mine (as well as from the mine of God's grace) within two months.

In 1863/64 the pit became penetrable with the pit of God's grace .

Even before 1867, a steam engine with an output of 40 hp was used to drain the pit. The hoisting machine had an output of 6 hp. It was dismantled by means of roof construction .

The pit marked dividing to the west with the pit Constanze and to the east with the pit Grace of God . To drain this pit, a tunnel several kilometers long was driven into the mountain from the pit of God's grace in 1883 . In 1944, this tunnel system was extended via the bar scale pit to the Constanze pit. The mine water , which is used today by the municipality Haiger as drinking water, came about in 1884 completed, called Dill cleats at Sechshelden in the dill .

Due to disregard of mining laws and various errors in blasting, springs dried up and the upper Donsbach valley was drained. In 1901, the water masses from the Stangenwage pit broke through the 45 m long safety pillar towards God's grace pit and from then on the water no longer flowed out of the tunnel mouth hole of the deep tunnel above Donsbach, but unhindered through the deeper dill tunnel into the dill .

At the beginning of the 20th century, the mine belonged to the Friedrich Wilhelms-Hütte in Mülheim. At that time, the ores were also merged there.

Delivery rates

The total value of mining from 1785-1844 was 296,071 florins and 56.5 kreuzers.

| Period | Flow rate (Fe) | Flow rate (Cu) |

|---|---|---|

| 1.11.1856 - 30.9.1858 | 586 t | |

| 1866 | ? | ~ 163 t |

| 1867 | 22,776 t | ~ 550 t |

| 1868 | 15,500 t | 560 t |

| 1869 | 15,688 t | 737 t |

| 1870 | 9,354 t | |

| 1871 | 8,625 t | |

| 1872 | 1,479 t | |

| 1906 | 15,894 t | 83 t |

Workforce

In 1857 162 workers were working in the mine. In 1872 there were 38 employees.

closure

The mine was finally closed in 1928 due to the exhaustion of the deposits. Today only the relatively large heap on which a farm stands today, the covered shaft and the name of the access road ( bar scale ) reminds of the former pit.

geology

In the southeast and east of the Rhenish Slate Mountains lies the so-called "Hessian Synklinorium", which also includes the Lahn-Dill area . The Hessian Synclinorium , which was formed by thrusting and folding in the Paleozoic ( Devonian ), has a complicated geological structure. It is characterized by fault lines, uplifts and faults. There are no large contiguous deposits in the Lahn-Dill area.

See also

literature

- Ernst Frohwein: Description of the Dillenburg mountain area , Bonn 1885

- Boehm: The ore deposits of the consolidated Stangenwage mine near Haiger, Dillenburg mining area . Prussian Journals 1905 Volume 53, pp. 259–297

Individual evidence

- ↑ a b c d e f Ernst Frohwein: Description of the Dillenburg mountain area . Bonn 1885.

- ↑ a b c d The mining and metallurgical industry in the Duchy of Nassau: statist. News, geognost., Mineralog. u. techn. Descriptions d. Deposits of usable minerals, d. Mining u. Hüttenbetriebes, Volume 2, Ed. F. Odernheimer, Publisher: CW Kreidel, 1867, Wiesbaden

- ^ A b Johann Philipp Becher: Mineralogical description of the Oranien-Nassauische Lande: together with a history of the Siegen smelting and hammering industry . 1789.

- ↑ CE Stifft: Geognostic description of the Duchy of Nassau in special relation to the mineral springs of this country , L. Schellenberg, Wiesbaden, 1831

- ↑ a b Der Bergwerksfreund: a newspaper for miners and smelters, for trades, as well as for all friends and promoters of mining and related trades, Volume 20, Reichardt, 1857

- ^ Donsbach's story ( Memento from April 26, 2018 in the Internet Archive )

- ↑ a b c d e Stahl und Eisen - Zeitschrift für das Deutschen Eisenhüttenwesen (27th year No. 43) of October 22, 1907, p. 1561

- ↑ Annual reports of the chambers of commerce and commercial corporations of the Prussian state: 1867, v. Decker, Berlin 1868

- ↑ a b Prussian statistics (official source work), Verlag der Königliche Wissense Ober-Hofbuchdruckerei (R. Decker), Berlin 1870

- ^ Journal of mining, smelting and salt works in the German Empire, Volume 16, W. Hertz, Berlin 1868

- ↑ Journal for mining, metallurgy and saltworks in the German Empire, Volume 18, Ernst, Berlin 1870