High entropy alloys

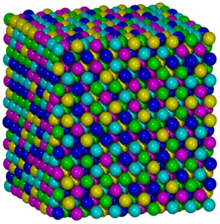

High-entropy alloys ( engl. High Entropy Alloy ) are materials consisting of a plurality of alloying elements are made with (almost) same alloy proportions. A lot of research is currently being carried out on them in materials science and engineering, as theoretically all imaginable material properties can be realized with them. Up to now, alloys consisted of one or two basic materials, the properties of which were improved by adding smaller amounts of alloying elements. An example is the importance of carbon in steel. For example, high entropy alloys can combine the TRIP and TWIP effects in one alloy.

history

High-entropy alloys have already been mentioned earlier in specialist articles, but they only found greater consideration after publications by Jien-Wei Yeh and Brian Cantor in 2004 or at the beginning of the 2010s, which independently of one another covered the field of high-entropy alloys described. The homatomic alloy FeCrMnNiCo also comes from Cantor. It is currently the most frequently examined high-entropy alloy.

Since high-entropy alloys have been examined more closely, the composition of matter Mo-Pd-Rh-Ru-Tc is also counted as a high-entropy alloy. This composition can be found in the form of particles on grain boundaries and on gas bubbles after fission in nuclear fuels. Since it contains the metastable isotope Tc-99m, which is used in medical technology , there is also greater research interest for this alloy.

definition

There is still no uniformly recognized definition of high-entropy alloys. Yeh originally defined high-entropy alloys as alloys that consist of at least 5 elements with an atomic fraction of 5 to 35 atomic percent . However, this definition is now recognized as insufficient. Otto et al. suggested that only alloys that form mixed crystals without intermetallic phases should be referred to as "true" high-entropy alloys, since the entropy decreases when an ordered, solid phase is formed.

Some authors already refer to alloys that are composed of 4 components as high-entropy alloys.

Alloy design

Conventionally, a main element (e.g. iron, aluminum, copper) is selected for the alloy design according to the properties. These elements are then improved by adding often small amounts of other elements or other properties are also added. Of course there are already binary alloy systems in which the amounts of the alloy components are almost the same (see Pb-Sn solders). However, research in the area of phase diagrams has so far concentrated on two- and three-phase systems and mainly on the edge areas or corner points, so that less is known about the middle areas in the phase diagram. Since systems with 4 or more components also have display problems in 2-dimensional space, even less is known about such systems.

Phase formation

With the help of Gibbs' phase rule , the maximum number of phases that theoretically result in an equilibrium system can be determined. At constant pressure there are 21 elements. Cantor designed an alloy of 20 different components (Mn, Cr, Fe, Co, Ni, Cu, Ag, W, Mo, Nb, Al, Cd, Sn, Pb, Bi, Zn, Ge, Si, Sb and Mg). All components had a share of 5 atomic percent. The result was mainly a face-centered cubic phase consisting mainly of Fe, Ni, Cr, Co and Mn, which also continued to exist in the solid state. Conventional alloys can only be mixed if the alloying elements have similar crystal systems (see Hume-Rothery rules). This does not apply to high entropy alloys.

thermodynamics

The high-entropy alloys produced all consist of mixed crystals. According to Yeh, this can be justified with the high entropy of mixing of any mixed crystal that has a large number of elements. Phases always try to adopt the lowest Gibbs energy level as possible . Therefore and with increasing entropy ( ) the probability of the formation of such stable high-entropy mixed crystals increases. The entropy of mixing can be calculated using the following formula:

with R the ideal gas constant , N the number of components and c i the atomic concentration of component i. It can be seen that alloys with the same concentration of components have a high entropy. You can also see that the entropy increases with additional components. An alloy consisting of 5 components (all with the same atomic concentration) has a mixing entropy of .

| parameter | property |

|---|---|

| ∆S mix | Maximize |

| ∆H mix | > −10 and <5 kJ / mol |

| Ω | ≥ 1.1 |

| δ | ≤ 6.6% |

| VEC | ≥ 8 for motor vehicles, <6.87 for short vehicles |

Furthermore, the enthalpy of mixing must be considered. This is calculated as follows:

with the binary enthalpy of mixing of components A and B and c i or c j of the atomic concentrations of components i and j. Zhang et al. found out through empirical studies that it is between −10 and 5 kJ / mol. Otto et al. describes that if it is already known in the investigated composition that two components also form mixed crystals in two-phase systems, the probability increases that mixed crystals will also form in multi-component systems.

Both thermodynamic parameters can be combined to form the new parameter .

where T m is the mean melting temperature of all alloy elements. should be greater than or equal to 1.1 for mixed crystal formation.

kinetics

The atomic radius of the individual components should be approximately the same so that mixed crystals form. Zhang et al. have introduced a new parameter to express the difference in atomic radii.

with r i the atomic radius of the element i and . For mixed crystal formation should be. In some alloys, intermetallic phases are formed.

Other properties

To assess whether the crystal structure is face-centered cubic (kfz) or body-centered cubic (krz), the valence electron concentration (VEC) can be considered. A mean valence electron concentration ≥ 8 will form a face-centered cubic crystal lattice, a mean valence electron concentration ≤ 6.87 will form a body-centered cubic crystal lattice. For valence electron concentrations in between, both kfz and krz crystal lattices will arise. In high entropy alloys containing chromium and vanadium, the valence electron concentration can also be used to predict the brittle σ phase .

Manufacturing

Special technologies are required to produce high-entropy alloys.

- Previous test samples were often melted in an electric arc or induction furnace .

- Another manufacturing option is mechanical alloying using a high-energy ball mill . Here, the pure metals are used in powder form. The ground powders can then be hot or cold isostatically pressed or spark plasma sintered for compaction . This method is particularly suitable for alloys in which the melting points of the individual components are very far apart (e.g. AlLiMgScTi).

- In addition, various alloys can be produced by gas phase processes (e.g. sputtering , molecular beam epitaxy ).

- Other options are thermal spraying , build-up welding and electroplating .

properties

Mechanical properties

The mechanical properties of the high entropy alloys depend heavily on the crystal structure formed. High-entropy alloys with a body-centered cubic crystal lattice often have a high yield strength and a low elongation at break (e.g. Al 7.5 Cr 22.5 Fe 35 Mn 20 Ni 15 ), while high-entropy alloys with face-centered cubic ones Crystal lattice is pronounced the other way around (e.g. CoCrMnNiFe).

In addition to its high elongation at break, CoCrMnNiFe also has very good mechanical properties at low temperatures. When cooling from room temperature to 77 K (−196.15 ° C), the yield point and the elongation at break increase. This is due to the formation of twins in the nanoscale due, a mechanism that does not occur at high temperatures. A possible application could be the use as a construction material at low temperatures . Due to the high strength, it can also be used as an energy absorption material. However, research has shown that these functions can also be achieved with conventional materials. When testing body-centered cubic AlCoCrNiFe up to 77 K in the notched impact test , the transition from deformation to brittle fracture could be observed.

Al 0.5 CoCrCuNiFe (face-centered cubic crystal lattice) shows a long service life and high fatigue strength in fatigue tests . However, aluminum oxide particles and microcracks had formed during the sample preparation , which means that the results show a high degree of scatter.

The single-phase, nanocrystalline alloy Al 20 Li 20 Mg 10 Sc 20 Ti 30 has a microhardness of 4.9 - 5.8 GPa with a density of 2.67 g / cm 3 , making it an alternative to ceramics (e.g. SiC ). However, the high cost of scandium is the limiting factor.

VNbMoTaW (body-centered cubic crystal lattice) has high tensile strengths even at very high temperatures ( tensile strength of approx. 650 MPa at 1400 ° C), which makes it suitable for applications in the refractory industry . However, the material is very brittle at room temperature and has a high density . There are still no publications on the creep properties .

By introducing oxides as so-called "ordered oxygen complexes" in z. B. titanium or zirconium alloys, materials with high strengthening and at the same time good ductility properties can be achieved.

Electrical and magnetic properties

CoCrCuNiFe (face-centered cubic crystal structure) has paramagnetic properties. The addition of titanium changes the crystal structure and, in addition to the face-centered cubic crystal lattice, there are amorphous areas and particles of the Laves phase in the nanoscale. The properties of the alloy change to superparamagnetic .

BiFeCoNiMn has a high magnetic coercivity . TaNbHfZrTi is a superconductor with a transition temperature between 5 and 7.3 K.

Other properties

The high-temperature oxidation behavior of high-entropy alloys has so far been little investigated. However, it has been shown that higher aluminum and chromium contents and lower iron contents have a positive effect on behavior.

The corrosion behavior in sulfuric acid or sodium chloride solution is comparable to that of stainless steels .

Individual evidence

- ↑ Shaoqing Wang: Atomic Structure Modeling of Multi-Principal-Element Alloys by the Principle of Maximum Entropy . In: Entropy . tape 15 , no. 12 , December 13, 2013, p. 5536–5548 , doi : 10.3390 / e15125536 , bibcode : 2013Entrp..15.5536W .

- ↑ according to HWAdmin: High-Entropy Alloys. In: Material magazine. March 21, 2017, accessed on January 16, 2019 (German).

- ^ High Entropy Alloys. Retrieved January 16, 2019 .

- ↑ KH Huang, Yeh JW. A study on multicomponent alloy systems containing equal-mole elements [MS thesis]. Hsinchu: National Tsing Hua University; 1996.

- ^ University of Bayreuth: Coordinated from Bayreuth: New DFG priority program on alloy research. Retrieved April 21, 2018 .

- ^ SC Middleburgh, DM King and GR Lumpkin: Atomic scale modeling of hexagonal structured metallic fission product alloys . tape 2 , no. 1 . Royal Society Open Science, London April 1, 2015, doi : 10.1098 / rsos.140292 .

- ↑ DB Miracle, ON Senkov: A critical review of high entropy alloys and related concepts . In: Acta Materialia . tape 122 , January 1, 2017, ISSN 1359-6454 , p. 448-511 , doi : 10.1016 / j.actamat.2016.08.081 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ a b J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin: Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes . In: Advanced Engineering Materials . tape 6 , no. 5 , 2004, ISSN 1527-2648 , p. 299-303 , doi : 10.1002 / adem.200300567 ( wiley.com [accessed January 16, 2019]).

- ↑ a b c F. Otto, Y. Yang, H. Bei, EP George: Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys . In: Acta Materialia . tape 61 , no. 7 , April 1, 2013, ISSN 1359-6454 , p. 2628–2638 , doi : 10.1016 / j.actamat.2013.01.042 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ Yu Zou, Soumyadipta Maiti, Walter Steurer, Ralph Spolenak: Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy . In: Acta Materialia . tape 65 , February 15, 2014, ISSN 1359-6454 , p. 85-97 , doi : 10.1016 / j.actamat.2013.11.049 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ a b B. Cantor, ITH Chang, P. Knight, AJB Vincent: Micro Structural development in equiatomic multi component alloys . In: Materials Science and Engineering: A . tape 375-377 , July 1, 2004, ISSN 0921-5093 , p. 213–218 , doi : 10.1016 / j.msea.2003.10.257 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ a b c d Y. Zhang, YJ Zhou, JP Lin, GL Chen, PK Liaw: Solid-Solution Phase Formation Rules for Multi-component Alloys . In: Advanced Engineering Materials . tape 10 , no. 6 , 2008, ISSN 1527-2648 , p. 534-538 , doi : 10.1002 / adem.200700240 ( wiley.com [accessed January 16, 2019]).

- ↑ a b c Yong Zhang, Ting Ting Zuo, Zhi Tang, Michael C. Gao, Karin A. Dahmen: Microstructures and properties of high-entropy alloys . In: Progress in Materials Science . tape 61 , April 1, 2014, ISSN 0079-6425 , p. 1–93 , doi : 10.1016 / j.pmatsci.2013.10.001 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ Sheng Guo, Chun Ng, Jian Lu and CT Liu: Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. Journal of Applied Physics, April 2011, accessed January 16, 2019 .

- ↑ Ming-Hung Tsai, Kun-Yo Tsai, Che-Wei Tsai, Chi Lee, Chien-Chang Juan & Jien-Wei Yeh: Criterion for Sigma Phase Formation in Cr- and V-Containing High-Entropy Alloys. In: Materials Research Letters. August 20, 2013, accessed January 16, 2019 .

- ↑ F. Otto, A. Dlouhý, Ch. Somsen, H. Bei, G. Eggeler: The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy . In: Acta Materialia . tape 61 , no. 15 , September 1, 2013, ISSN 1359-6454 , p. 5743-5755 , doi : 10.1016 / j.actamat.2013.06.018 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ Z. Wu, H. Bei, F. Otto, GM Pharr, EP George: Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys . In: Intermetallics . tape 46 , March 1, 2014, ISSN 0966-9795 , p. 131–140 , doi : 10.1016 / j.intermet.2013.10.024 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ AJ Zaddach, RO Scattergood, CC Koch: Tensile properties of low-stacking fault energy high-entropy alloys . In: Materials Science and Engineering: A . tape 636 , June 11, 2015, ISSN 0921-5093 , p. 373–378 , doi : 10.1016 / j.msea.2015.03.109 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ MA Hemphill, T. Yuan, GY Wang, JW Yeh, CW Tsai: Fatigue behavior of Al0.5CoCrCuFeNi high entropy alloys . In: Acta Materialia . tape 60 , no. 16 , September 1, 2012, ISSN 1359-6454 , p. 5723-5734 , doi : 10.1016 / j.actamat.2012.06.046 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ Khaled M. Youssef, Alexander J. Zaddach, Changning Niu, Douglas L. Irving and Carl C. Koch: A Novel Low-Density, High-Hardness, High-entropy Alloy with Close-packed Single-phase Nanocrystalline Structures. Materials Research Letters, December 9, 2014, accessed January 16, 2019 .

- ↑ New 'high-entropy' alloy is as light as aluminum, as strong as titanium alloys. Retrieved January 16, 2019 (American English).

- ↑ CM Liu, HM Wang, SQ Zhang, HB Tang, AL Zhang: Microstructure and oxidation behavior of new refractory high entropy alloys . In: Journal of Alloys and Compounds . tape 583 , January 15, 2014, ISSN 0925-8388 , p. 162–169 , doi : 10.1016 / j.jallcom.2013.08.102 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ ZD Han, N. Chen, SF Zhao, LW Fan, GN Yang: Effect of Ti additions on mechanical properties of NbMoTaW and VNbMoTaW refractory high entropy alloys . In: Intermetallics . tape 84 , May 1, 2017, ISSN 0966-9795 , p. 153–157 , doi : 10.1016 / j.intermet.2017.01.007 ( sciencedirect.com [accessed on January 16, 2019]).

- ^ Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Retrieved January 16, 2019 (American English).

- ↑ XF Wang, Y. Zhang, Y. Qiao, GL Chen: Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys . In: Intermetallics . tape 15 , no. 3 , March 1, 2007, ISSN 0966-9795 , p. 357-362 , doi : 10.1016 / j.intermet.2006.08.005 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ Chen-Zhong Yao, Peng Zhang, Meng Liu, Gao-Ren Li, Jian-Qing Ye: Electrochemical preparation and magnetic study of Bi – Fe – Co – Ni – Mn high entropy alloy . In: Electrochimica Acta . tape 53 , no. 28 , November 30, 2008, ISSN 0013-4686 , p. 8359-8365 , doi : 10.1016 / j.electacta.2008.06.036 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ S. Vrtnik, P. Koželj, A. Meden, S. Maiti, W. Steurer: Superconductivity in thermally annealed Ta-Nb-Hf-Zr-Ti high-entropy alloys . In: Journal of Alloys and Compounds . tape 695 , February 25, 2017, ISSN 0925-8388 , p. 3530-3540 , doi : 10.1016 / j.jallcom.2016.11.417 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ Ming-Hao Chuang, Ming-Hung Tsai, Woei-Ren Wang, Su-Jien Lin, Jien-Wei Yeh: Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys . In: Acta Materialia . tape 59 , no. 16 , September 1, 2011, ISSN 1359-6454 , p. 6308–6317 , doi : 10.1016 / j.actamat.2011.06.041 ( sciencedirect.com [accessed January 16, 2019]).

- ↑ Peter K. Liaw, Wei He, Lu Huang, Zhi Tang: Alloying and Processing Effects on the Aqueous Corrosion Behavior of High-Entropy Alloys . In: Entropy . tape 16 , no. 2 , February 2014, p. 895–911 , doi : 10.3390 / e16020895 ( mdpi.com [accessed January 16, 2019]).