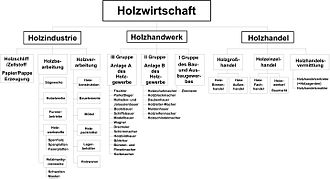

Timber industry

The timber industry is the branch that deals with the economic utilization of the raw material wood . It includes the timber trade, the timber industry and the timber trade.

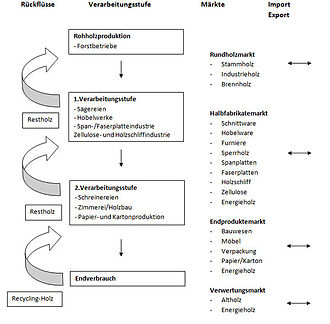

The timber industry gets its raw material from the forestry that produces the wood , the international timber trade and, to a small extent, from recycling . For the production and refinement of wood-based materials, the development of machine and plant systems is part of the corporate purpose of large companies in the wood-based materials industry from a technical and economic point of view. Large quantities of by-products are generated in the woodworking processes. These are further processed as by- products or used to generate bioenergy ( cascade use ).

More than a third of the earth's land mass is covered with forest. The life of around a quarter of the world's population is directly or indirectly dependent on the forest and its products. Wood as a building material and energy carrier plays an important role in this context. The pressure on forests and wood will continue to increase due to population growth. The timber industry has become global since the end of the Cold War at the latest. The material flows are therefore complex, since many countries are importers and exporters at the same time. The transport costs for wood are now relatively low, which is why it is traded globally.

Structure of the timber industry

Timber trade

The collective term timber trade is understood to mean the economic activity of procuring goods that mainly consist of the raw material wood and / or conveying them to further processing buyers or end consumers. The transactions are summarized under the term Holzmarkt. The central task of the wood trade is to supply the processing craft businesses, wood-based materials manufacturers and construction companies as well as do-it-yourselfers with wood and wood products. The price development for wood is primarily determined by its character as a raw material and the technical development in processing and use. Due to the increasing demand for the renewable material, prices will rise globally in the medium to long term. From a global perspective, the following categories represent the most important types of products for retail: raw wood , sawn timber , waste wood , panel trade, pulp and paper .

Raw wood trade

Since 1985 the international raw wood trade has increased by a good 40%. The proportion of coniferous wood is more than 50% of all round wood exports. The largest exporter of softwood is Russia with a share of over a third. The main importing countries of coniferous wood are Japan and China, both of which have only small available wood reserves. In terms of volume, tropical logs are the most exported from Malaysia, Gabon, Papua New Guinea, Indonesia and Myanmar. The main importing countries again include China and Japan as well as India.

Cutlery trade

Between 1985 and 2000 the global cut goods trade increased by 40%. 90% of sawn timber exports come from North America and Europe. The USA is one of the most important importers, and 40% of its needs come from Canada. The rest of the sawn timber trade takes place mainly in Europe, but Asia is also increasingly developing into an important import market.

Record trade

The trade in panels pressed from wood experienced an upswing in the 1990s with the MDF panel . Germany and China are the main exporters of fiberboard. Particleboard is mainly exported from Canada and Germany. Asia (Indonesia, Malaysia and China) shows high growth rates with the production of plywood . The USA is the largest importer of wood-based panels.

Pulp and wood pulp trade

World trade increased by 75% between 1985 and 2000. The main exporters are Canada, the USA, Sweden and Brazil. The most important import countries are the USA, Japan and Germany.

| Trade types | |

|---|---|

| Trade types | Offers purchased, mostly raw wood goods, for further processing to other trading companies, commercial wood processing companies, or bulk consumers. |

| Timber retail | The timber retail trade is the sale of semi-finished wood products for production. Retail goods are mainly sold to private households. |

| Timber foreign trade | Includes the import and export of wood from abroad. |

| Raw wood trade | The raw wood trade supplies forest wood to the sawmill industry, wood-based materials industry and the paper and pulp industry. |

| Product groups | |

|---|---|

| raw materials | Trunk wood, industrial wood, sawing by-products, waste paper, waste wood / raw wood trade |

| Semi-finished goods | Veneer, plywood, sawn timber, chipboard, fiber boards, cellulose, wood pulp, timber trade, trade in other semi-finished wood products |

| Finished goods | Construction timber, building elements, interior work, furniture and furnishings, transportation materials, industrial uses, paper products |

Timber industry

The term wood industry describes all companies that deal with the treatment and processing, or with the refinement and utilization of the raw material wood. The branches of the wood industry include the sawmill industry, the wood-based materials industry, the veneer industry and the pulp and paper industry. The semi-finished and finished goods produced in the individual sectors are in turn used in other economic sectors.

Wood craft

Numerous professional fields are represented in the wood industry. In addition to traditional training such as carpenter / carpenter, carpenter or handicraft professions such as turner or wooden toy maker and niche trades such as boat builder or cooper, there are also many professions that are generally in demand in industry. The wood craft has a tradition wherever wood is available as a local raw material.

Importance of the timber industry

Economical meaning

The contribution of the timber industry to the national economy of a country is usually given as a percentage of the gross domestic product . The higher the proportion, the greater the economic importance. However, a large proportion of forest does not necessarily mean that the timber industry plays an important role in the national economy, as this depends on the other economic sectors in the country. From a global perspective, the contribution of the wood industry to GDP has decreased as other economic sectors have grown faster. The added value increases with increasing processing depth. If only round timber is produced in a country and no further processing is carried out, the entire potential for added value cannot be exploited.

Sustainable use of wood

The term sustainability is used for the first time in the German language in the font Silvicultura oeconomica, which was written in 1713 by Hans Carl von Carlowitz. In the forestry sense, sustainability means a long-term, responsible use of resources or that no more wood may be felled than can grow back. In 1987, the World Commission for Environment and Development defined the concept of sustainability in the Brundtland Report as a procedure that allows all people living today to meet their needs without endangering the opportunities of future generations.

With regard to the use of wood, sustainability means that the supply of wood as a raw material is to be ensured through long-term management of the forests and that the utilization of the raw material is planned in such a way that the raw material is also available to future generations.

Wood as a building material plays an important role in minimizing the consequences of climate change . Sustainably used commercial forests, in which as much wood is removed as it grows back, are natural CO 2 stores, as the tree stores the carbon in the wood that has been removed from the atmosphere . The raw material wood therefore makes a contribution to carbon fixation with long-term use, especially through cascading use.

The global goal of sustainable wood use is particularly endangered by various human activities in the rainforests and primeval forests. The reasons for the endangerment of the tropical rainforests include, in addition to legal and illegal logging, also the clearing of forest fires for agricultural purposes. 56% of total raw timber to be seen around the world about the firewood used, especially in emerging and developing countries to a overuse leads or destruction of forest land. In some developing countries, up to 80% of the timber yield is used as fuelwood. This is why there is often no sustainable use of wood, especially in emerging and developing countries. The reasons for this are poor political and economic framework conditions, a lack of knowledge, corruption, the growing world population and poverty.

Measures to preserve rainforests and primeval forests are the establishment and maintenance of protected areas, whereby these are often endangered by political and economic instability, sustainable forest management and the introduction of certificates and labels for sustainable forest management. The following organizations belong to the most important certificates and labels:

| abbreviation | complete designation | description |

|---|---|---|

| FSC | Forest Stewardship Council | The FSC was founded in 1993 by environmental groups, socially responsible organizations and representatives from industry. The FSC is an accreditation organization for certification and inspection companies. In a broader sense, the certification of wood products according to the FSC also includes the product chain. |

| PEFC | Program for the Endorsement of Forest Certification Schemes | PEFC is an international forest certification system that aims to promote the local, sustainably produced raw material wood through natural forest management. |

| ITTA | International Tropical Timber Agreement | The International Tropical Timber Agreement is an international environmental and trade agreement and a government organization with the aim of ensuring sustainable international trade in tropical timber. |

| CITES | Convention on International Trade in Endangered Species of Wild Fauna and Flora | CITES is an agreement and an international organization that aims to control international trade in wild animals and plants to such an extent that the survival of wild animal and plant species is not endangered. |

| EFI | European Forest Institute | The EFI is an international organization of European countries. The main objective is research on forest policy, including the various aspects that must be taken into account when designing forest policy. |

| FLEGT | Forest Law Enforcement, Governance and Trade | The FLEGT action plan was adopted by the EU Commission in 2003 and aims to prevent illegally felled timber from being imported into the EU and thus to contribute to the fight against illegal logging and more sustainable forestry in the timber exporting countries. |

| ATFS | American Tree Farm System | The ATFS is the largest certification system in America. The ATFS standard for certification belongs to the

American Forest Foundation, a national non-profit organization. |

| CSA (SFM) | The Canadian Standards Association Group Sustainable Forest Management System (SFM) | The CSA (SFM) is Canada's official national standard for sustainable forest management. |

| SFI | Sustainable Forestry Initiative | The SFI is a North American non-profit organization.

The SFI program only certifies states in the United States and Canada. Program participants must comply with all applicable laws. |

Cascade use

The term cascade use means the multiple use of a raw material over several stages. If possible, wood should be used as a material in a first step. This has the decisive advantage that the CO 2 saving is twice as effective: By using wood products, CO 2 emissions from other raw materials are avoided. In addition, the secondary use of waste and waste wood as an energy source can prevent additional emissions from fossil fuels.

Raw materials and products from the timber industry

raw materials

The raw materials used in the timber industry can be divided into the following categories:

| Round wood | Felled, decapitated and / or delimbed trees as well as tree parts in a round and (lengthways) undivided shape. |

| Logs | A range of logs intended for material use, particularly in the sawing or veneer industry. |

| Solid wood / solid wood | Wood products are referred to as solid wood, the cross-sections of which have been carved out of a tree trunk and possibly further processed by cutting. The structure of the wood is not changed mechanically or mechanically and chemically. |

| Lumber | Sawn timber is a timber product that is made by sawing round timber parallel to the trunk axis. It can be sharp-edged or have tree edges. |

| Lumber | Lumber is wood that is used as a building material for the construction of buildings and other structures. Depending on the shape and degree of processing, a distinction is made between various timber products, which are classified into the categories solid wood, glued laminated timber and wood-based materials. Various standards define quality requirements and properties that the timber products must meet, depending on their use. |

| Glulam BSH | Glued laminated timber is understood to be composed of at least three board layers and wood glued in the same grain direction. They are mainly used in timber engineering, i.e. with high static loads. |

| Wood-based materials HWST | Wood-based materials are materials that are produced by chopping wood and then joining the structural elements together. The size and shape of the wood particles ultimately determine the type of wood material and its properties. |

| Industrial wood | Industrial wood is raw wood that is not processed further as solid wood or sawn wood, but is mechanically shredded or chemically digested in further processing for the production of HWST panels, wood-based materials, cellulose or paper. |

| old wood | Waste wood is wood that has already been used for a purpose. Waste wood can be recycled materially, for example in the wood-based materials industry, or thermally. |

| Waste paper | Waste paper is paper waste that is collected in households or businesses. It is used to make recycled paper and other paper products such as cardboard. An important process when using waste paper is printing ink removal (deinking). |

Product groups

The products of the timber industry are diverse. They range from building materials for interior and exterior construction to wooden houses, to a wide variety of everyday objects for furniture, to musical instruments and raw materials for paper, cardboard, the chemical industry and firewood. One possibility to distinguish the products is the material and energetic use.

Material use

- Semi-finished goods

- Finished goods

- HWST

- Paper carton

- cellulose

- Furniture

- Lumber

- Tonewood

- Veneers

Energetic use

- Pellets

- Logs

- briquette

- Bioenergy

Timber industry in Germany

The largest part of the timber industry in Germany is medium-sized and predominantly based on craft. Most of these are family businesses located in rural areas, including sawmills, timber trade, furniture, packaging and prefabricated construction industries. There are only a few companies that have a large industrial structure. These large industries produce mainly in the wood-based materials and pulp and paper industries.

Timber trade

The assortment of the timber trade is diverse. This includes sawn timber, planed goods or wood-based panels as well as construction elements such as ceiling and facade cladding or doors. There is also the specialization of the trade in raw wood and veneers, which supplies the sawmills, wood-based materials industry or the paper industry. The timber trade achieved a turnover of almost 13 billion euros in 2008.

Foreign trade

The export surplus based on the values of the entire German foreign trade in wood results mainly from the balance of the upper group of finished goods, as can be seen in the graphic. The net export in 2012 amounts to around five million euros. The positive trade balance is mainly due to the paper and printed products product group.

Timber industry

Along with stone, wood is the oldest material known to man. In the Middle Ages and in the early modern period, many smaller timber companies emerged in Germany. Since the beginning of the use of steam and electricity in the 19th century, one can speak of a wood industry in Germany. At the same time, traditional small-business craft structures were retained. Due to the strong natural forest cover, there are companies in the wood industry all over Germany. Traditionally located near larger forest areas, many companies are small to medium-sized and are often still family-owned.

Timber transport

Until the middle of the 20th century, rafting was a common means of transporting bulky logs over long distances. With the advent of the railroad, it increasingly took over the transport of logs. The current share of round wood transports by rail is around 9%. Today a large part (around 90%) of the more extensive timber transports are carried out with the help of trucks due to the flexible use. From these the logs felled in the forest, piled up in piles and sold are removed for further use. Transport by ship only plays a marginal role at around 1%.

Sawing industry

The wood cut in the forest is mostly first processed in the sawmill, where the raw wood is processed into sawn timber. The German sawmill industry is by far the largest consumer of raw wood in Germany and thus the most important link between forestry and the timber industry. More than 37 million cubic meters of wood were cut and processed in the local sawmills in 2012.

The sawing industry is distributed very differently in Germany. While there are many smaller sawmills in the densely wooded southern Germany, medium-sized to very large sawmills have settled in northern and eastern Germany. While small factories tend to process regional wood, large sawmills also pay off to buy over longer distances or to import from abroad.

Almost three quarters of German sawmills are softwood companies. This means that more than 90% of the coniferous wood is cut there. By contrast, only around nine percent of the sawmills are designated hardwood businesses with a comparable concentration. 17% of the sawmills are mixed operations. Both groups of wood species are cut there.

Wood materials industry

The wood-based materials industry has around 15,000 employees and an annual turnover of around 5.6 billion euros. In Germany, around 20 million cubic meters of wood are required for the manufacture of wood-based materials every year.

Veneer industry

Only valuable woods of good quality are processed into veneers. The hardwoods beech and oak dominate, each with around 30% market share. Wood types such as birch, cherry, ash and coniferous wood range from five to seven percent. Maple has a market share of ten percent.

Pulp and paper industry

With a turnover of over 15 billion euros and 40,000 employees, Germany is the largest paper producer in Europe. In a global comparison, the German paper industry ranks fourth. Every year, more than ten million cubic meters of weak forest wood and saw raw materials are required for the production of paper , cardboard and cardboard in Germany. The annual production is almost 23 million tons. Around 3000 different types of paper are produced.

Carpenters and timber construction

The German carpentry and timber construction industry had sales of around 6.3 billion euros in 2013. The number of employees is growing steadily due to the continuing growth in construction activity in the area of new construction and renovation. A good 80% of the companies have between one and nine employees. Only a very small proportion of three percent has more than 20 employees. The future development in the German carpentry trade depends very much on how timber construction develops. The largest share of sales is 49% in existing buildings. In the entire residential construction sector, the trend is still increasing.

Furniture industry and prefabricated construction

In Germany, furniture worth around 16.2 billion euros was produced in 2013 , which means a decrease in production of three percent compared to the previous year. The decline can be observed in almost all areas. The export quota of the furniture industry is around 35%. The most important sub-sectors of the industry are office and shop furniture as well as kitchens and seating furniture.

Carpenters and joiners

The focus of the industry is on interior design and furniture construction. Almost 185,000 people are employed in more than 42,000 companies. They generate an annual turnover of more than 17 billion euros.

Energy generation

In the context of the discussion on the question of renewable energies, wood plays an important role as a renewable raw material. By far the most important bioenergy carrier in Germany is wood, which is used in the form of logs, wood chips or pellets. The domestic consumption of wood raw materials has increased continuously over the past two decades and is currently around 130 million cubic meters per year. The wood raw materials include forest wood, waste wood (used wood), landscape maintenance material, but also industrial waste wood that is already contained in forest wood. A total of around 77 million material and around 53 million cubic meters are used for energy every year.

Wood craft

Vocational training

The wood craft has a long tradition in Germany due to the historical use of wood. Numerous professional fields are represented in the wood industry. In addition to traditional training such as carpenter, carpenter or (art) craft professions such as turner or wooden toy maker and niche trades such as boat builder or cooper, there are also many professions that are generally in demand in industry. The training follows i. d. Usually the dual system of company and vocational school.

- Accountant

- Construction machinery operator

- Professional drivers

- Business economist

- Office clerk / man

- Chemical laboratory assistant

- Chemist

- Controller

- Dispatcher

- Electrician

- Energy and system electronics technician

- Energy system electronics technician

- Precision mechanic

- Forklift driver

- Commercial clerk / woman

- Woodworking mechanic

- Wood technician

- Holzwirt / in

- Hotel specialist

- Industrial electrician

- Industrial clerk / man

- Industrial mechanic

- IT clerk / woman

- Parquet layer

- Paper technologist

Education

Classic courses in the wood industry at technical colleges and universities are wood management, wood technology, wood construction and finishing. We are also looking for process technicians, mechanical engineers, chemists, paper engineers, wood managers and IT engineers / computer scientists. Numerous universities offer diploma and specialization courses in wood construction, wood industry or wood technology in the field of civil engineering or production technology. Among others in Germany at the following institutions:

| Educational institution | courses |

|---|---|

| University of Applied Sciences Rottenburg aN | Timber industry |

| University of Hamburg | Timber industry |

| DHWB Mosbach | Wood industry and wood technology |

| Bielefeld University of Applied Sciences | Civil engineering |

| University of Applied Science and Art | Civil and wood engineering |

| www.hawk-hhg.de | Wood technology |

| Technical University of Braunschweig | Civil engineering |

| RWTH Aachen | Wood technology and civil engineering |

| University of Karlsruhe | Civil engineering |

| Technical University Berlin | Civil engineering |

| Technical University of Munich | Civil engineering |

| Technical University Dresden | Wood technology and timber industry |

| Ostwestfalen-Lippe University of Applied Sciences | Wood technology |

| Rosenheim University of Applied Sciences | Wood processing, wood technology, wood construction and expansion, interior construction |

| University of Cooperative Education Dresden | Wood and wood-based panel technology |

| Leibniz University Hannover | Civil engineering |

| Deggendorf University | Civil engineering |

| Rhine-Main University of Applied Sciences | Wood and steel construction |

| University for Sustainable Development Eberswalde | Wood technology |

| BA-Melle | Wood technology, focus on the furniture, interior design and construction industries |

Economic importance

In the timber industry, the statistics for 2010 show 93,451 companies with a turnover of 165.4 billion euros, added value of 50.5 billion euros and 1.04 million total employees .

In 2011 there were 93,624 companies in the wood industry in Germany. They generated sales of EUR 173.95 billion and employed 1.042 million people. The deviations from the graphic result from the time lag and the absence of forestry employees.

Total wood balance in Germany

The total wood balance records the total amount and consumption of wood and wood-based products, i.e. all wood-based materials, in Germany. The total volume includes the domestic felling, the domestic volume of waste paper and waste wood, imports and the outflow of stocks.

Logging

In 2012 around 52.3 million cubic meters of wood were felled in Germany. Around 75% of the logging was in coniferous wood such as spruce, fir, Douglas fir and larch, and a good 40% of the total logging took place in private forests.

Further data can be found in the article raw wood .

Total volume

The graphic shows the total wood volume in the time series from 1991 to 2012 in million m³. With the exception of 2007 (Hurricane Kyrill) and 2009 (peak of the economic crisis), the total volume in Germany has leveled off at a stable level. According to the official logging statistics, the level of felling in German forestry is regularly around 93% below the level of domestic consumption of raw wood. In 2012, 124.4 million m³ of wood or wood products were imported into Germany, which corresponds to a reduction of 4.4% compared to the previous year.

Total usage

The graphic shows that total use has increased steadily, which is largely due to the increase in exports. Domestic consumption is largely constant at 100 million m³ annually.

Waste wood

In 2010 the trade volume amounted to 8.1 million tons, of which 9% were used internally. Around a fifth of the waste wood goes to waste wood processors and a good three quarters is sold directly to the end user. Distribution via the disposal companies to end users takes place primarily to domestic customers. 19% of the waste wood from the German disposal system goes to the chipboard industry and 78% to energy recovery.

Waste paper volume

The domestic volume of waste paper accounts for 19% of the total volume and has remained largely constant at 44.5 million m³ annually.

Associations of the timber industry in Germany

Umbrella associations of the German timber industry

| abbreviation | complete designation |

|---|---|

| DHWR | German timber industry council |

| HDH | Main association of the German wood industry |

Raw wood consumer

| abbreviation | complete designation |

|---|---|

| EGR | Arbeitsgemeinschaft Rohholz eV |

| DeSH | German Sawmill and Wood Industry Association |

| BAV | Federal Association of Waste Wood Processors and Recyclers |

| VHI | Association of the German Wood Materials Industry |

| BS wood | Glued laminated timber |

| VDP | Association of German Paper Mills |

Timber industry

| abbreviation | complete designation |

|---|---|

| VDM | Association of the German Furniture Industry |

| VdDP | Association of the German Upholstered Furniture Industry |

| so | Association of office, seating and contract furniture |

| VdDW | Association of the German Home Furniture Industry |

| AMK | Working group The Modern Kitchen |

| VdDK | Association of the German Kitchen Furniture Industry |

| BDF | Federal Association of German Prefabricated Buildings |

| LETTER | Federal association for interior construction, element and prefabricated construction |

| IFN | Veneer + Nature initiative |

| HPE | Federal Association of Wood Packaging, Pallets, Export Packaging |

| vdp | Association of the German Parquet Industry |

| VFF | Association of windows and facade |

| IPM | Pro Solid Wood Initiative |

| dlv | Network shopfitting |

| Carpenter joiner Germany | Carpenter Carpenter Germany Federal Guild Association |

| Timber construction Germany | Timber construction Germany Bund Deutscher Zimmermeister in the Central Association of the German Building Industry |

| Funeral supplies | Federal Association of Funeral Needs |

| Glued wood construction | Study group wood glue construction |

| Wooden pavement | Association of wood pavers |

Trade and service providers

| abbreviation | complete designation |

|---|---|

| CDH | Central Association of German Business Associations for Trade Brokerage and Sales |

| VDMA | Association of German mechanical and plant engineering |

| GD wood | General Association of German Timber Trade |

literature

- Taschenbuch der Holztechnik, André Wagenführ, Frieder Scholz, 2nd edition 2012, Carl Hanser Verlag, ISBN 978-3-446-42605-4

Individual evidence

- ^ FOA Yearbook 2000 and Timber Bulletin United Nations 2004

- ^ RVR: Framework agreement for the round timber trade in Germany

- ^ RVR: Framework agreement for the round timber trade in Germany

- ↑ Publication "Naturally Wood, Forestry and Wood Management in Germany", Holzabsatzfond (2008)

- ↑ Archive link ( Memento from October 29, 2014 in the Internet Archive )

- ↑ Timber construction Germany: Management report and statistics. Retrieved January 12, 2020 .

- ↑ https://www.destatis.de/DE/PresseService/Presse/Pressemitteilungen/2014/01/PD14_014_421.html

- ↑ Publication "Naturally Wood, Forestry and Wood Management in Germany", Holzabsatzfond (2008)

- ↑ Brief info on bioenergy. Retrieved January 12, 2020 .

- ↑ Seintsch, Björn: Cluster forest and wood according to the new economic branch classification, tables for the federal territory and the states 2000 to 2011

- ↑ http://literatur.vti.bund.de/digbib_extern/bitv/dn049040.pdf

- ↑ Archive link ( Memento from October 6, 2014 in the Internet Archive )

Web links

- German Timber Industry Council V. (DHWR) - umbrella organization of the German timber industry

- Main Association of the German Wood Industry (HDH) - the leading association of the German wood industry

- Arbeitsgemeinschaft Rohholz e. V. (AGR)

- Initiative Holz Pro Klima - Why wood protects the climate

- Information from the state of North Rhine-Westphalia on the state's timber industry

- Internet presence of the German saw and wood industry Bundesverband e. V. , on May 9th, 2013 emerged from the Federal Association of the German Sawing and Wood Industry (VDS) and the Federal Association of Sawing and Wood Industry Germany e. V. (BSHD)

- Internet presence of the Gesamtverband Deutscher Holzhandel e. V. (GD Holz) , with comprehensive information on the wood trade, wood properties, wood use, etc.