Lumber

Construction wood (also construction wood ) is wood that is used as a building material for the construction of buildings and other structures . Depending on the shape and degree of processing, a distinction is made between various timber products, which are classified into the categories solid wood, glued laminated timber and wood-based materials . Various standards define quality requirements and properties that the timber products must meet, depending on their use. Higher quality classes are sometimes differentiated from construction timber as so-called solid construction timber. The disposal of construction and demolition wood ( waste wood disposal ) is regulated in the waste wood ordinance .

properties

Wood is a good building material for many reasons, e.g. B. because of the low density with high rigidity at the same time , the good processability , the resistance ( durability ), load-bearing capacity , etc. These properties depend heavily on the type of wood , the wood components used ( heartwood , sapwood ), the processing, the wood protection and many other factors from.

Various standards help ensure certain qualities in construction timber. In Germany z. B. According to DIN 1052, only certain types of wood are permitted for use for load-bearing purposes:

- Conifers : spruce , fir , pine , larch , Douglas fir , western hemlock , southern pine and yellow cedar .

- Hardwoods : Oak , Beech , Teak , Keruing , Afzelia , Merbau , Angélique (Basralocus) , Bongossi and Greenheart .

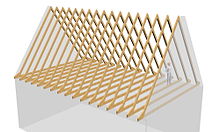

The processing of timber in construction takes place in the area of shell construction (erection and repair of roof structures , construction or assembly of prefabricated houses , repair and new construction of half-timbered houses , etc.). These activities fall into the realm of carpenters .

Other wood products are used in the building industry, but they do not actually belong to construction timber. These are e.g. B. windows , doors or parquet . In concrete construction too , wood is often used for auxiliary structures, e.g. B. as formwork , which is also not counted as construction timber.

Solid wood

As solid wood or hardwood timber products referred to, the cross-sections of a tree trunk worked out and possibly by machining (drilling, milling, planing, etc.) were processed. In contrast to glued laminated timber and wood-based materials, the structure of the wood is not changed mechanically or mechanically and chemically.

When it comes to solid wood, a distinction is made between round wood and sawn wood :

Construction timber

Construction round wood consists of delimbed, debarked or round peeled tree trunks or trunk sections, also known as round wood . These are often used without further processing as a post / peg , for example as posts or supports , driven piles (pilot), masts , palisades , for the construction of playground equipment and in hydraulic engineering , e.g. B. as dolphins used.

In Germany, quality requirements for structural timber are in DIN 4074 Part 2 Timber for timber components; Quality conditions for building timber. (Softwood) defined.

Processing logs directly is one of the most original forms of use of wood in construction. However, since whole trunks tend to tear open all the way down to the core, a more complex drying process and the use of suitable carpenter connections is a prerequisite. Modern building timber, on the other hand, is usually milled to an exact diameter and kiln dried .

Typical areas of application for round timber, historical and current, partly for technical reasons, partly because of the rustic appearance:

- Traditional log house construction , especially where material is used on site, such as more remote farms and huts, forest and hunting lodges , alpine huts , barns and stacks , and the like

- simple outbuildings (warehouses, agricultural buildings, car shelters, pavilions)

- Equipment for playgrounds

- Fences , railings and similar barriers

- simpler bridges (footbridges and cycle paths), footpaths for hiking trails and alpine trails , boat and bathing jetties , and the like

- Poles for low voltage overhead lines or telephones

- Noise barriers

- Avalanche barriers and hydraulic engineering

- Palisades

Lumber

Lumber is made from round timber by sawing it parallel to the trunk axis, has a minimum thickness of 6 mm and usually a rectangular or approximately rectangular cross-section. It can be cut with sharp edges or still have remains of the contour of the tree trunk.

Requirement for use as structural timber for load-bearing purposes, such as B. roof trusses , in Germany the sorting is according to the load-bearing capacity according to DIN 4074 (part 1 for coniferous sawn timber and part 5 for hardwood sawn timber ). The sorting according to the Tegernsee customs , which was often used in the past, is no longer relevant for construction timber, but is still commercially available. DIN 4074 was included in the building regulations list as a product standard and has been introduced by the building authorities . Lumber for structural purposes must therefore meet the sorting criteria of this standard.

Solid structural timber

As construction timber refined lumber is known that meets 4074 increased quality requirements according to an association agreement between the collar German carpenters and monitoring Konstruktionsvollholz against the DIN. It consists of softwood squared timbers of the wood types pine, fir, larch, Douglas fir or spruce. A distinction is also made between solid structural timber for the visible area (KVH-Si) and solid structural timber for the non-visible area (KVH-NSi). As a rule, KVH is a finger-jointed solid wood product made from softwood. This means that any length can be produced. According to EN 1995-1-1, Section 3.2, Paragraph 5, finger joints must meet the requirements of EN 385. According to EN 1995-1-1 / NA, NCL to 3.2, finger-jointed solid wood may only be used in service classes 1 and 2. The usage classes are defined in EN 1995-1-1, Section 2.3.1.3. For KVH, the strength, rigidity and bulk density values for solid wood apply. The characteristic values are given in EN 338.

In Germany, lumber is divided into different product classes according to DIN 4074-1, depending on the cross-sectional shape and dimension:

- Squared timber

- As a squared timber , the timber is referred to by fogging (forms of the squared timber by ax) or sawing with four in right angle to one another is provided protruding edges which the cross-sectional area yield. Squared timber is used both in construction and in furniture joinery . They serve as table legs, struts, armrests and much more. As structural lumber, squared lumber has a minimum thickness of 4 cm according to DIN 4074 structural lumber (or 6 cm DIN 68252 for commercial goods in general), the cross-section height being a maximum of three times the width. Boards and planks that are mainly subjected to edgewise bending must be sorted like squared timber according to DIN 4074-1 and marked accordingly. Important areas of application of square timber are or were z. B. Rafters , columns and trusses .

- bar

- The bar is the colloquial form for the technical designation of a square timber, which more or less relates to the type of application / purpose or dimension. The longer side of the cross section of the beam measures at least 20 cm. Often beams are used to construct wooden joist ceilings .

- Plywood

- For efficient use of the raw wood and the industrial production of dimensionally stable and crack-minimized beams, two to five boards, planks or square timbers are glued together flat-sided and parallel to the fibers to form beams.

- Laminated beams from two or three solid wood layers are as a duo beams and triple beams called. The terms lamellar timber , lamellar beams and glued timber should be avoided due to the risk of confusion with glued laminated timber . Laminated timber may only be used in service classes 1 and 2 in accordance with DIN EN 1995-1-1 / NA, Section NCL NA.3.8, Paragraph NA.2 and requires general building inspectorate approval in accordance with Paragraph NA.1. With the exception of the modulus of elasticity parallel to the fiber, according to approval Z-9.1-440, the strength, rigidity and bulk density values for solid wood apply.

- As with solid structural timber and glued laminated timber, wood layers with finger joint connections are usually used. The only difference to glued laminated timber is the use of larger individual cross-sections.

- Glued laminated timber is manufactured in accordance with European DIN EN 14080: 2013, whereby in Germany the associated application standard DIN 20000-3: 2015 must be observed. The previous general building authority approval Z-9.1-440 continues to apply for the time being.

- Bohle

- As structural timber, a plank has a thickness of at least 40 mm and a width of at least three times its thickness.

- board

- A board has a maximum thickness of 40 mm and a width of at least 80 mm. Boards for the production of glued laminated timber can also have a thickness greater than 40 mm.

- bar

- A lath is also up to 40 mm thick, but in contrast to a board has a maximum width of 80 mm.

Glued laminated timber

With glued laminated timber larger dimensions, freer forms and higher strengths can be achieved than with solid timber. The natural limitations of the dimensions are overcome, and wide-span engineering structures ( timber engineering ) can be carried out, which are economically and structurally competitive with reinforced and prestressed concrete .

As a rule, the individual wood layers in glued laminated timber run parallel to the shorter side of the cross-section. The opposite is often the case with laminated timber.

Wood-based materials

Wood-based materials are materials that are produced by chopping wood and then joining the structural elements together. Examples are plywood , chipboard materials ( chipboard , OSB panels ) or wood fiber materials ( hardboard , MDF panels ).

Norms

Various standards are relevant for construction timber:

EN standards

- EN 1995-1-1: 2010-12 Corresponds to the European standard EC5 and is only valid in conjunction with the corresponding national standards.

- DIN EN 1995-1-1 / NA: 2010-12. It replaces DIN 1052: 2008-12

- ÖNORM B 1995-1-1 (2004 / A1: 2008) / NA: 2009 In Austria the national annex (NA) has been introduced by the building authorities (6/2009) and must be used there.

- EN 338: 2003 Structural timber for load-bearing purposes - Strength classes

- EN 1194: 1999 Timber structures - Glulam - Strength classes and determination of characteristic values

DIN standards

- DIN 1052: 2008-12 Calculation and dimensioning of timber structures - General dimensioning rules and dimensioning rules for building construction.

- DIN 4074:

- DIN 4074-1 (2003-06) Sorting wood according to load-bearing capacity - Part 1: Softwood lumber.

- DIN 4074-2 (1958-12) Timber for wooden components ; Quality conditions for building timber (softwood).

- DIN 4074-5 (2003-06) Sorting wood according to load-bearing capacity - Part 5: Hardwood lumber .

- is also binding for Austria as ÖNORM DIN 4074-x

- DIN 68252-1 Terms for sawn timber , shape and dimensions.

Web links

- Private website depicting traditional methods of making construction timber by cutting and sawing logs. Georg Hefter, accessed on March 6, 2019 .

Individual evidence

- ↑ Examples based on the use of round timber . rundholz-seibald.at (accessed October 26, 2016).

- ↑ Sorting of structural timber according to load-bearing capacity - sorting criteria for softwood and hardwood according to DIN 4074-1 and -5. In: Holzfragen.de. Expert office for wood protection, accessed on March 6, 2010 .

- ↑ Hans-Joachim Rüpke: Finger-jointed solid wood, glued laminated timber and glued laminated timber - useful information about the use as load-bearing wooden components outdoors on Holzfragen.de

- ↑ Product description glued laminated timber (Duobalken® / Triobalken®) on Balkenschichtholz.org