Hybrid Synergy Drive

Hybrid Synergy Drive (abbr. HSD ) is a brand name for the hybrid drive system of Toyota . This is or was for the Toyota Prius (all models), Toyota Corolla Hybrid, Toyota Auris Hybrid, Toyota Auris Touring Sports , Toyota Yaris Hybrid, Toyota RAV4 Hybrid, Toyota Camry Hybrid, Toyota C-HR Hybrid and for various Lexus models such as CT200h, RX400h, GS450h and LS600h offered. In America and Japan it is also offered in other Toyota models and is licensed to Nissan, Ford and Mazda.

Hybrid cars are far more popular in the US than in Europe. In 2010, 291,000 hybrid vehicles were sold in the US, compared to only 110,000 in Europe. Hybrid cars are the most common in Japan. 492,000 units were sold there in the same year.

Versions

The drive system used in the first mass-produced vehicle with hybrid drive ( Toyota Prius 1997) became known as the Toyota Hybrid System (THS) . In 2003 the second generation of the Prius (NHW20) with the improved THS-II came onto the market. This system appeared under the brand name Hybrid Synergy Drive (HSD for short). The Hybrid Synergy Drive has been the drive unit of the Toyota Prius since model year 2003 (as of May 2006). A more powerful version of the THS-C is used in hybrid vehicles from the Lexus brand . The manufacturer markets this system under the name Lexus Hybrid Drive. A further developed HSD was introduced in the third version of the Toyota Prius (since 2009). The Toyota Auris HSD (since 2010) and the Lexus CT 200h , which has been available since 2011, use an identical system to the Prius 3.

use

The first car with HSD was the Toyota Prius. Toyota is now also installing the HSD in other automobiles. These are: Toyota Alphard , Toyota Auris , Toyota Auris Touring Sports , Toyota C-HR , Toyota Camry , Toyota Highlander , Toyota Previa , Toyota Prius Plug-in Hybrid , Toyota Prius + , Toyota RAV4 and Toyota Yaris .

At Toyota subsidiary Lexus , the HSD, which is called Lexus Hybrid Drive there, is offered in the following models: Lexus CT , Lexus IS , Lexus GS , Lexus HS 250h , Lexus LS 600h , Lexus NX and Lexus RX .

Toyota also licenses this technology to Nissan , Ford and Mazda : Nissan offers the HSD in the Nissan Altima , Ford in the Ford Escape Hybrid and Mazda since 2013 in the Mazda3 .

From 1997 to 2019 Toyota sold over 13 million HSD vehicles. The HSD comprises 24,000 patents and Toyota granted competitors free use of the HSD for their vehicles until 2030 in order to further spread the economical HSD technology and its advantages.

construction

The HSD is a unit consisting of an internal combustion engine and two motor-generators as well as a high-capacity accumulator and an electronic control unit. The HSD is a power-split hybrid drive in which the power of the combustion engine and the electric motors are distributed with the help of the power split device . The structure of the HSD is described using the example of the third generation Toyota Prius.

Power split device

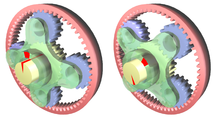

Yellow (and largely covered): the sun gear; it is connected to the motor generator MG1 in the HSD. Blue: the planet gears; the internal combustion engine of the HSD drives the planet carrier shown in green. Red: the ring gear; it is connected to motor generator MG2 and gives torque to the drive wheels.

The Power Split Device consists of a planetary gear and an electronic control. It determines the transmission ratio of the transmission between the internal combustion engine and the output shaft. It also makes it possible to adjust the power flow depending on the control of the motor-generators. There is no coupling, all components are positively connected to each other in every operating state .

The internal combustion engine is connected to the planet carrier, the sun gear to the smaller motor generator MG1. The ring gear of the planetary gear is the power delivery point of the HSD. The larger motor generator MG2 is also connected to this.

The internal combustion engine

All vehicles with HSD that have been on the market to date (2016) use a spark-ignition four-stroke combustion engine with camshaft adjustment . Since the second generation of the Prius, it has been operated in the Atkinson cycle . It has four cylinders, a displacement of 1.8 liters and an output of 73 kW (Toyota Prius & Auris, Lexus CT 200h).

The motor-generators

The two electrical units of the HSD are called "motor generators" by Toyota because they can function as both a generator and a motor. They are abbreviated as MG1 and MG2. The electrotechnically correct designation for this type of motor is three-phase synchronous machine with permanent magnet excitation .

The less powerful MG1 (42 kW for model generation 3) is used to start the combustion engine and mostly as a generator while driving. By changing its speed, the transmission ratio with which the internal combustion engine delivers its power to the ring gear and thus to the drive wheels is also set.

The more powerful MG2 is used as a direct drive motor and as a recuperation brake to recover braking energy. The third generation of the Prius has an output of 60 kW.

Batteries

An important element of the HSD is the high-performance battery pack. This is considerably more powerful than the starter batteries used in conventional cars. It is a nickel-metal hydride battery , while starter batteries are almost without exception lead-acid batteries . A lithium-ion battery with 4.4 kWh is used in the Prius PHV, which will be available from 2012 (net charging window used approx. 3.0 kWh). In the Toyota Prius + a smaller Li-Ion battery is used.

The voltage of the Ni-MH battery pack is 201.6 volts. It has a maximum output power of 27 kW (third generation), which is also the maximum power available for the electric motors with which the combustion engine can be supported. For comparison: the voltage of a conventional car starter battery is 12 volts, its maximum output approx. 2 kW.

The high-performance battery of the HSD was designed for high cycle stability. Since it is also never fully charged and discharged (from 40% to usually 60%, with recuperation downhill up to a maximum of 80%), its service life is as long as that of the vehicle itself. The evaluation of the data is approx. 36,000 Toyota Prius showed that these vehicles - and thus also the batteries - were extremely reliable. In a test carried out in the USA, the performance of a new Toyota Prius was compared with that of a vehicle that had driven more than 300,000 km after ten years. Acceleration and consumption remained almost the same, which suggests that the performance of the battery had hardly decreased.

In addition to this battery pack, every car with HSD also has a conventional, considerably smaller 12-volt battery. If, in the event of a fault, the high-voltage circuit and the high-performance Ni-MH battery fail while driving, this ensures that the on-board electronics continue to function with 12 volts DC. Since this battery is not intended to start the combustion engine, it has a lower capacity than conventional starter batteries.

The boost converter

The Boost Converter, which has existed since the second generation of the Prius, increases the voltage of the Ni-MH battery from 201.6 volts to a maximum DC voltage of up to 650 volts (Prius 3, up to 500 V for Prius 2), which means - after conversion into three-phase current - the motor-generators are fed. When MG1 and / or MG2 work as a generator, it converts their three-phase current of up to 650 volts (up to 500 V for model generation 2) into DC charging voltage of just over 200 volts.

Inverter

By means of a inverter ( inverter ) 650 V is DC voltage into a variable-frequency three-phase current converted by which the motor generators are supplied. Both electric motors, the boost converter and the inverter, are water-cooled by a circuit that is independent of the combustion engine. A second inverter converts the direct voltage of 201.6 volts from the hybrid battery into a three-phase alternating voltage of the same level in order to feed the air conditioning system. This inverter has been integrated in the housing of the electric drive / air conditioning compressor since model generation 3.

Position and speed sensors

A number of sensors are active in the HSD. The most important are: Position and speed sensors for MG1 and MG2, with which not only the current speed, but also the exact angular position of both motors can be determined. By measuring the current balance, the exact torque acting on the respective motor generator is also known.

Additional sensors record the position of the accelerator and brake pedals and the position of the gear lever.

Control electronics

Several electronic modules, so-called ECUs (Electronic Control Units), work in the HSD.

- HV ECU (High Voltage Electronic Control Unit): It controls the flow of energy between the battery and the two motor generators. The HV ECU also monitors the safe operation of the hybrid drive and saves operating data for easy troubleshooting. In the event of a fault, it can shut down the high-voltage circuit with the help of three relays.

- Skid Control ECU: It controls and monitors regenerative braking.

- Battery ECU: It monitors the charge status of the battery pack and controls the cooling.

Stages of development

Since its introduction in 1997, the HSD has seen numerous improvements. The internal combustion engine of the Toyota Prius I had a displacement of only 1.5 liters and an output of 43 kW, whereas the Prius ZVW30, which was presented in 2009, had an internal combustion engine with a displacement of 1.8 liters and an output of 73 kW. The largest combustion engine that is used in an HSD today is a V8 engine with a displacement of 5 liters and an output of 290 kW in the Lexus LS 600h. In parallel to the performance of the combustion engine, the performance of the electric motors and thus the performance of the overall system also increased.

The two motor-generators in the first-generation Prius were operated with a voltage that was identical to the voltage of the battery pack of 274 volts. The first Prius model sometimes had problems with overheating of the power electronics. Therefore, this was water-cooled from the second generation. In this generation, the battery voltage has been reduced to 201.6 volts, which is increased to 500 volts for the motor generators with the boost converter. In the Prius III, the converter works with a peak voltage of 650 volts.

Due to the direct connection, the speed of MG 1 was identical to the speed of the sun gear in the Prius of the first and second generation and the speed of MG 2 was identical to the speed of the ring gear. The third generation HSD (used e.g. in the Prius ZVW30 from 2009), on the other hand, has another planetary gear that halves the speed of the ring gear and thus that of the sun gear. In the Prius of the first and second generation, the maximum permissible speed of MG 1 limited the maximum speed at which you can drive in purely electric mode. Thanks to the additional planetary gear, it is now possible to drive electrically at higher speeds, which is particularly important with the Prius PHV, which has significantly more powerful batteries. An additional transmission is also used in the THS-C, a further development by Lexus.

Since the internal combustion engine is operated with HSD with a high degree of efficiency, there is also little waste heat to heat the engine, catalytic converter and vehicle interior. This problem was met in the third generation HSD, as used in the Prius ZVW, with a heat recovery system. It was further improved in the Toyota Prius + , which was unveiled in 2012.

A newly developed "pitch and bounce control" control system was also used in this vehicle, which dampens the vehicle's rocking caused by nodding movements on poor roads by appropriately activating the drive.

function

The Hybrid Synergy Drive is easy to use for the driver; To ensure this and to ensure an optimal operating condition, a number of control loops are constantly active.

Driving with the HSD

The regulation of the speed and load distribution of all motors as well as the charge status of the batteries are controlled fully automatically by the electronics of the HSD. The driver only chooses whether he wants to drive forwards or backwards and how much he wants to accelerate or brake. As with a conventional car, the accelerator and brake pedals accelerate and brake, but the electronics decide which motors or generators are used and how. By selecting different travel programs, it is possible to influence the switching points of the electronics. In this way, the vehicle can either be driven as sportily as possible or as sparingly as possible. Alternatively, you can drive exclusively electrically for a certain time.

Pressing the accelerator pedal while stationary usually causes the electric motor MG2 to accelerate first; When a certain speed is reached, the combustion engine is started fully automatically and without jerking. It can now contribute to the acceleration, take over the acceleration alone, or both accelerate and charge the batteries at the same time with the help of the electric motors now acting as generators. When braking, if the braking power is low, the generators first brake and the energy is fed into the batteries. The conventional brakes are only involved in the braking process if the required braking power is higher than the battery charging power. All of this happens fully automatically and cannot be influenced by the driver.

The operating modes of the HSD

The gear ratio and thus the speed of the internal combustion engine is set via the speed of the sun gear, that is to say of the motor generator MG 1. The combustion engine can be operated over a wide range of speeds from standstill to maximum speed. However, the maximum speed of MG 1 limited the controllable range in the models before the Prius III; With the THS and THS-II, the combustion engine cannot rotate at low speeds at the speed of its maximum output; therefore, the power of the internal combustion engine and the large motor generator MG 2 are used together for quick start-up. The combustion engine cannot be stopped at very high speeds, since in this case the maximum speed of MG1 (or both electric motors in the Prius III) would also be exceeded. The combustion engine and one of the two motor-generators both serve to propel the vehicle and can perform this task alone or in combination. Motor generator MG 1 serves primarily as a generator and starter. The hybrid vehicle can assume the following operating states:

- Starting with a pure electric drive, power is supplied by the battery; MG 1 and MG 2 rotate in opposite directions, the carrier of the planetary gears is stationary.

- Driving with the combustion engine:

- MG 1 stands

- The combustion engine drives the vehicle, MG 1 charges the battery

- Combustion engine and MG 2 drive the vehicle, MG 1 supplies the required electricity

- The combustion engine and MG 2 drive the vehicle, the accumulator supplies the required electricity

- Rolling : The combustion engine is off, the MG 1 applies a slight pre-braking, should it be necessary to brake, the braking energy can be used to charge the battery

- Braking with the motor generator: The combustion engine is off, braking energy is used to charge the accumulator

- Braking with the motor generator and the hydraulic ("conventional") brake; Braking energy is used to charge the accumulator.

- Motor brake: This mode is only activated if the accumulator is already too charged to absorb more energy when the braking power is low (usually on long downhill journeys). The braking energy is then converted into heat by the motor, which turns without fuel, in order to prevent the disc brakes from overheating and wearing out.

Advantages and disadvantages of the concept

An internal combustion engine cannot operate at a speed close to zero. A mechanical clutch is therefore required to start off in cars with manual transmissions. With automatic transmissions, the power generated when the car is at a standstill (in gearbox position D) and at very low speeds is fed into the hydraulic converter . In both cases, engine power is converted into heat and can therefore no longer be used. In contrast to the combustion engine, an electric motor - as with the Hybrid Synergy Drive - can be operated from zero speed, as it then already supplies usable torque . In contrast to a mechanical coupling, there are no friction losses here either.

A gasoline engine has a lower output at low speeds . In order to have a power reserve available in the car at all times, the low engine speed that is optimal in terms of consumption is rarely used. Rather, the driver selects a lower gear and thus a higher speed than is actually necessary for the required power. The internal combustion engine is thus operated with a relatively low load. The efficiency of a gasoline engine is significantly reduced at low loads, which u. a. caused by throttle losses .

In a conventionally powered car, the driver or the automatic transmission can drive with a high load and high efficiency by accelerating in high gear; however, if more power is required, it can only be achieved by increasing the speed, i.e. by selecting a lower gear. Shifting and changing the speed of the internal combustion engine take time.

Since the energy density of batteries available today is far lower than that of gasoline or diesel, the batteries of a purely electric vehicle are disproportionately quickly emptied or disproportionately large, heavy and expensive when driving overland and motorway, despite the significantly higher efficiency of the electric motor. This speaks in favor of hybrid drives, which combine both advantages.

advantages

The Hybrid Synergy Drive allows the speed and power of the combustion engine to be regulated relatively independently of the required drive power. If the combustion engine is used, it can be operated with a constantly high load and thus with high efficiency. With the Hybrid Synergy Drive, a rapid power requirement can be served directly with the motor generator MG 2, while the gear ratio is changed in parallel with the aid of motor generator MG 1 in order to increase the speed and power of the internal combustion engine. As a result, the internal combustion engine can always be operated with a high degree of efficiency without sacrificing comfort.

Further advantages are:

- The combustion engine does not idle unnecessarily; With the exception of the warm-up phase, the internal combustion engine is only started if it can also be operated with good efficiency; At low speeds or when little or no drive power is required, the combustion engine is switched off. This happens not only when stopping at a red light, but also when driving downhill, when the driver takes off the accelerator completely, or, for example, in a speed limit of 30 .

- The HSD enables uninterrupted acceleration over the entire speed range. The internal combustion engine is always started and stopped smoothly and without any interruption of tractive power.

- If the driver of a car with a manual shift takes off the accelerator completely, the fuel consumption drops to 0 due to the overrun cut-off. However, the vehicle is then always braked by the engine brake, even if the driver did not want to brake at all. In a vehicle with HSD, the same braking effect is achieved with the help of the electric motors, which in this case feed a certain amount of power into the accumulators as a generator. If this regenerative brake is not desired, it can be stopped by lightly tapping the accelerator pedal, with which an effect like that of a freewheel can be achieved. In a car with a manual gearshift, the driver would have to put it in neutral and switch off the engine, which is not advisable for safety reasons, as switching off the engine would also render systems such as power steering and brake booster inoperable.

- Since a large part of the braking energy that arises is used to charge the batteries (= recuperation ), brake wear is lower, and so is consumption when driving up and downhill. Braking energy can also be reused in some conventionally powered cars; However, the batteries of the Hybrid Synergy Drive allow a higher charging current and thus greater braking power to be used for recuperation than would be possible with conventional starter batteries.

- The overall efficiency of the HSD is around 45% compared to 40% of a diesel engine and 35% of a conventional Otto engine.

- While the combustion engine is idle, the car is extremely quiet to noiseless, which contributes to relaxed driving (red traffic lights, traffic jams, downhill driving). This is also useful when the car is to be moved in a noise-sensitive environment.

- When the internal combustion engine warms up to heat the interior or to warm up the catalytic converter quickly (to minimize pollutant emissions), it charges the battery.

- The HSD drives like a car with an automatic transmission. The driver only chooses whether he wants to drive forwards or backwards.

- The steadily increasing number of electrical consumers in recent years places a much greater load on the electrical system of today's cars than was previously the case, for which batteries and alternators have to be dimensioned accordingly (examples: start-stop system , auxiliary heating , seat heating , rear window heating , lighting , Car radio , etc.); The alternator and batteries increase the weight of the vehicle, but are not required for driving. With the Hybrid Synergy Drive, very powerful batteries and generators are carried along, which are not only used when the vehicle is stationary, but also when driving.

- With the high-performance batteries required for the hybrid drive, when the combustion engine is at a standstill, units can be fed that would overload the existing battery capacity in conventional cars (e.g. the air conditioning).

- The electrical operation of auxiliary units, which are driven by the combustion engine in conventional cars, allows more efficient operation (air conditioning, power steering, water pump for engine cooling, brake booster).

- Since the engine cooling is operated electrically, the combustion engine can be switched off safely immediately after a longer full load requirement, without heat accumulation in the engine block, because the cooling water pump can continue to run even when the combustion engine is at a standstill.

- A major advantage of this hybrid concept is the avoidance of partial load runs in which conventional gasoline engines can only be operated with very poor efficiency. Diesel engines , however, work considerably more efficiently than gasoline engines in partial load operation - the HSD does not benefit to the same extent compared to diesel engines when it comes to partial load runs. Therefore, the consumption benefit from the combination of diesel engine and HSD is rather limited.

- Since an engine that works in the Atkinson cycle produces less waste heat, the engine cooling system can be made smaller. This not only lowers manufacturing costs, space requirements and weight, but also reduces the air resistance due to a smaller radiator surface, and it shortens the warm-up phase of the internal combustion engine due to the smaller amount of coolant. This lowers pollutant emissions, which are highest in all gasoline engines during the warm-up phase.

disadvantage

Compared to a comparable vehicle with a combustion engine:

- The batteries and power electronics carried along increase the weight of the vehicle and reduce the size of the available trunk. Since the hybrid battery is housed under the rear seat of the Auris II and Yaris, there are still no trunk restrictions compared to the non-hybrid versions. In the case of the Yaris and Auris, the hybrid variant is slightly heavier than the pure gasoline engine variants, but lighter than the diesel models.

- Since the combustion engine is operated with high efficiency, less waste heat is generated for the interior heating. In the 3rd generation Prius, this is compensated for by exhaust gas heat recovery. Otherwise, energy from the hybrid system has to be used for heating, which somewhat diminishes the advantage at the start of the journey.

- The combustion engine initially turns relatively high when the accelerator pedal is strong (e.g. on the acceleration lane on a motorway entrance). This can be perceived as annoying due to the resulting engine noises. The continuously variable transmission needs a little time when accelerating strongly / accelerating to adjust the transmission ratio and thus to lower the engine speed of the combustion engine.

- The maximum total system output of the Prius III (100 kW) is only available for a few seconds to max. three minutes available - until the battery is empty. After that, the car only has the power of the combustion engine (73 kW). The full system performance is only available again after a sufficiently long journey with less than 73 kW load, during which the battery is being recharged. This disadvantage is noticeable on long journeys at full throttle on the mountain and also when pulling a trailer. When accelerating for a short time z. B. but it does not occur when overtaking, because afterwards and before the battery is charged again.

- The underuse of the brakes due to recuperation sometimes leads to the build-up of rust on the brake discs , which has to be sanded off again through targeted braking.

Compared to an electric car:

- "Cheap driving with electricity from the socket" is only possible with additional accessories (the vehicle then becomes a "plug-in hybrid").

- Due to the small battery, the purely electric range is only a few kilometers (typically 2–3 km). With additional batteries from third-party providers, ranges of up to approx. 30 km can be achieved.

Special features / peculiarities

- The hybrid components do not increase the weight of the vehicle to the extent that the weight of the additional electric motors and batteries initially appears, because it is partly offset by the omission of other assemblies such as clutch, alternator, starter and gearbox.

- The power provided by the electric motors in addition to the combustion engine at full load of the overall system is determined by the maximum permissible current, i.e. H. the maximum output power of the accumulator of 27 kW (third generation) is limited. This is lower than the maximum power of the electric motors. If the combustion engine is not operated at full load, it can generate additional electricity via the generator, which is then used again in the second electric motor. In this case, the electric motor can deliver more than the battery power of 27 kW to the wheels, e.g. B. when reversing.

- The combustion engine can only be switched off while driving up to a certain speed; If the combustion engine is stationary, the faster the vehicle drives, the higher the speed of the electric motors. The maximum permissible speed of the electric motors thus limits the maximum speed up to which the combustion engine can be switched off. MG 1 had a limiting effect on Prius models of the first and second generation, as its speed was significantly higher than that of MG 2. An additional reduction gear is installed in the third generation of the Prius so that MG 1 and MG 2 run at almost identical speeds.

- Since the systems required for driving (power steering, oil pump, brake booster, air conditioning) must also be available when the combustion engine is at a standstill, they must also function independently of this. They are therefore powered electrically, which, however, contributes indirectly to savings in fuel consumption, since the hybrid system can generate electrical energy efficiently.

- The Hybrid Synergy Drive reduces fuel consumption, among other things, by recovering kinetic energy into electrical energy when the vehicle is braked . At a largely constant speed, e.g. B. when driving on the motorway, HSD has a lower consumption advantage. The basic fuel consumption advantage through the variable ratio and the engine operated in the Atkinson cycle, however, also persist on the highway, as this engine has the highest efficiency of all internal combustion engines with spark ignition.

Trivia

- The Prius was used as a generator to supply the house electrical system (in the event of a power failure due to a storm). A maximum of 1000 W could be drawn from a voltage converter connected to the Prius DC high-voltage electrical system. As soon as the drive battery was empty, the combustion engine started to recharge it. In this way, 1 kWh of electricity could be generated from one liter of gasoline consumption, which is quite competitive with electricity generation with a small gasoline-powered generator. The advantage here is that there is no unnecessary idle consumption and that exhaust gases are cleaned via the catalytic converter.

See also

Web links

- Description of the Hybrid Synergy Drive at Toyota

- Control of an electromechanical transmission for hybrid vehicles

- Interactive animation that clearly shows the interaction of the two engine generators with the combustion engine

annotation

- ↑ Explanatory calculation: One kilowatt hour (kWh) is 60 kilowatt minutes. 1.3 kWh are therefore 78 kilowatt minutes. 78 kilowatt minutes / 27 kilowatts = 2.88 minutes. In reality, the possible delivery time of the maximum power is well below 2.88 minutes, since the battery is neither fully charged nor completely discharged to increase the service life.

Individual evidence

- ↑ Archive link ( Memento from October 16, 2011 in the Internet Archive )

- ↑ toyota.de, accessed on January 7, 2015 ( Memento from October 23, 2014 in the Internet Archive )

- ↑ https://www.reuters.com/article/us-toyota-patents/toyota-to-give-royalty-free-access-to-hybrid-vehicle-patents-idUSKCN1RE2KC

- ↑ Burress, Timothy A., et al. Evaluation of the 2010 Toyota Prius hybrid synergy drive system . No. ORNL / TM-2010/253. Oak Ridge National Laboratory (ORNL); Power Electronics and Electric Machinery Research Facility, 2011 (PDF, 7.24 MB), available on September 7, 2018.

- ↑ a b c d Autoshop101.com Toyota Hybrid System, Course 71, Section 2, Online, PDF ( Memento from October 2, 2011 in the Internet Archive )

- ↑ a b Green Car congress: Toyota previews Prius V at www.greencarcongress.com from May 24, 2011, available on September 7, 2018.

- ↑ a b Specs of the Toyota Prius III

- ↑ The 200,000-mile question: How does the Toyota Prius hold up? ( Memento from September 25, 2011 in the Internet Archive )

- ↑ 3rd Generation Toyota Hybrid (eCVT) Transaxles Youtube Video from Weber State University In the video, John D. Kelly explains the difference between the third generation HSD with second planetary gear and the previous versions (English)

- ↑ Diezeitistreif.ch questions and answers about the new Toyota Auris ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ^ Werner Clement: Vehicle transmission online at Google Books

- ↑ Süddeutsche Zeitung of June 2, 2004: The great hubris of the hybrid, article by Heiko Barske Online ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ online ( Memento from July 1, 2008 in the Internet Archive )

- ↑ http://box.motorline.cc/autowelt/pdf/toyota_prius_funktion.pdf (PDF, 388 kB), available on September 7, 2018.

- ↑ Ice storm 2013: Toyota Prius powers Thornhill man's home thestar.com