Multi-chip module

A classic multi-chip module ( MCM , sometimes also MCP from English Multi Chip Package ) consists of several individual microchips (or dice ) that are housed in a common housing planar (next to one another) and look like a chip on the outside function and be used. From the outside, such chips are not directly recognizable, but look like many others. Today, the name MCM is also used for modules that, in addition to semiconductor dies, have micromechanical elements or discrete passive components such as B. Capacitors or resistors in SMD designs (see surface-mounted device ) . Such MCMs and MCMs with vertically arranged components (see below die-stacking) correspond much more to the characteristics of a system-in-package (see also " system-in-package ") .

The individual chips can be specially designed for integration in an MCM. Then you usually have to do with individual chips in completely different technologies that cannot simply be integrated into a single die. Examples here are primarily digital microcontrollers and their analog peripheral components and / or flash memories , sometimes also microprocessor cores and their otherwise external cache components, and finally, in cell phones, the combination of processor, SRAM and flash memory. In the field of intelligent sensors (such as pressure sensors ), z. B. Evaluation chip and micromechanics packed in a housing. This approach is usually a cheaper alternative to the monolithic integration of all components in a semiconductor (see “ System on a Chip ”) .

However, chips can also be used that are otherwise installed and used alone in the housing. This is the case when you want to save the development time for a completely integrated chip for small series or a quick shot. The connection to an MCM can be developed much faster.

For functionality it is usually necessary to electrically connect the individual chips to one another. This is done in the same way as they are otherwise used in microelectronics : direct bonding on miniaturized circuit carriers (lead frames, substrates, circuit boards ). Thus, an MCM is a special case of an electronic flat module (compact module). Another important assembly method is z. B. Flip Chip .

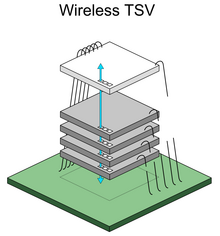

If several chips are stacked one on top of the other, one speaks of die -stacking or a system-in-package (SiP). So that the complete component does not get too high when the dies are stacked, the dies are sometimes ground thin beforehand with some effort. They are then potted like ordinary chips, bonded to the external pins and packaged in a housing. A new method of connecting stacked dies with one another is called TSV (for Through-Silicon-Vias ). As with multilayer circuit boards, the die layers are contacted through holes. Too many of these cannot be stacked directly on top of each other, otherwise overheating problems will arise due to the more difficult heat dissipation.