Peltier element

A Peltier element [ pɛl.tje ] is an electrothermal transducer which, based on the Peltier effect (according to Jean Peltier , 1785–1845), generates a temperature difference when current flows through or a current flow ( Seebeck effect ) when there is a temperature difference . Peltier elements can be used both for cooling and - if the current direction is reversed - for heating. A common abbreviation for Peltier elements and Peltier coolers is TEC ( thermoelectric cooler ).

Principle, basics

The basis for the Peltier effect is the contact of two semiconductors with different energy levels (either p- or n-conducting) of the conduction bands . If a current is passed through two consecutive contact points of these materials, heat energy must be absorbed at the one contact point so that the electron can get into the energetically higher conduction band of the neighboring semiconductor material, which leads to cooling. At the other contact point, the electron falls from a higher to a lower energy level, so that here energy is given off in the form of heat.

Since n-doped semiconductors have a lower energy level of the conduction band, cooling takes place at the point where electrons pass from the n-doped to the p-doped semiconductor (technical current flow from the p-doped to the n-doped semiconductor).

The effect also occurs with metals, but is very slight here and is almost completely overlaid by the heat loss and the high thermal conductivity .

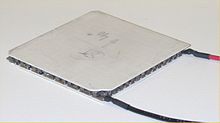

A Peltier element consists of two or more small cuboids each made of p- and n- doped semiconductor material ( bismuth telluride , silicon germanium ), which are alternately connected by metal bridges at the top and bottom. The metal bridges also form the thermal contact surfaces and are insulated by an overlying film or ceramic plate. Two different cuboids are always connected to one another in such a way that they form a series connection . The electrical current supplied flows through all the cuboids one after the other. Depending on the strength and direction of the current , the upper junctions cool down while the lower junctions heat up. The current thus pumps heat from one side to the other and creates a temperature difference between the plates.

The most common form of Peltier elements consists of two mostly square plates made of aluminum oxide - ceramic with an edge length of 20 mm to 90 mm and a distance of 3 mm to 5 mm, between which the semiconductor cuboids are soldered. For this purpose, the ceramic surfaces are provided with solderable metal surfaces on their facing surfaces.

Without further measures, the heat difference between the cold or hot side of the Peltier element and the environment (e.g. air) can mainly only be compensated for by thermal radiation, much less by convection. The amount of heat transported between the hot and the cold side remains the same, however, and so does the temperature difference. The temperature difference between the two sides can, depending on the element and current, be up to approx. 70 Kelvin for single-stage elements.

If the convection is increased on one side by means of an attached heat sink with a fan , a temperature closer to the ambient temperature will set on this side. The temperature on the other hand will vary further from the ambient temperature accordingly. A heating resistor can convert electricity into heat much more easily, so the cooling effect is the more interesting task of a Peltier element and so the hot side is typically actively ventilated in order to intensify the cooling effect.

The reverse of the Peltier effect is the Seebeck effect . It is thus possible to generate electrical voltage by creating a temperature difference between the two sides of a Peltier element (see also thermoelectric generator , energy harvesting ).

Efficiency

Important factors for the efficiency (similar to the efficiency ) of a Peltier element are the thermal conductivity and specific resistance of the semiconductor material used. The heat flow generated is proportional to the electrical current. The temperature difference between the sides creates a return flow of heat in the element, proportional to the temperature difference and the thermal conductivity. The flowing current creates heat loss, which increases quadratically with the current strength and is proportional to the specific resistance. The efficiency ( coefficient of performance ) as the ratio of the electrical energy used to the usable heat flow therefore falls - doubling the electrical current doubles the heat flow, but quadruples the heat loss. The heat return flow can be reduced if efficient heat conduction on the outer surfaces (heat sink, ventilation) is provided, and the temperature difference is thus kept low.

In summary, the efficiency decreases with increasing electricity and increases with good heat supply and removal.

Advantages and disadvantages

The greatest advantages of a Peltier element are the small size, the low weight, the avoidance of any moving components, gases and liquids. A refrigeration machine , on the other hand, always requires a refrigerant and in most cases a compressor .

By reversing the direction of the current, Peltier elements allow both cooling and heating. In this way, temperature control of components can also be achieved when the ambient temperature is above or below the setpoint temperature.

A disadvantage of the Peltier elements is the low efficiency of approx. 1/10 of the Carnot efficiency , which leads to a high electrical power consumption with a comparatively low cooling capacity or temperature difference. Furthermore, elements larger than 40 mm × 40 mm are hardly available.

use

Peltier elements can be used wherever cooling is required with a small temperature difference or without economic requirements. Peltier elements are used, for example, in cool boxes in which the use of a refrigeration machine is forbidden for reasons of space or would not be profitable because the required cooling capacity is low. A temperature difference between inside and outside is simply generated in an uncontrolled manner. The efficiency is low.

Peltier elements are used to cool particularly long-wave or sensitive CCD sensors . This significantly reduces the image noise with long exposure times (e.g. in astrophotography ) . Multi-stage Peltier elements are used to cool radiation receivers in infrared sensors.

Peltier elements are also being used more and more frequently in laboratory measuring devices for which temperature is an essential parameter, such as density measuring devices , viscometers , rheometers or refractometers .

In dew point mirror hygrometers, one or more Peltier elements connected in series usually cool the mirror down to -100 ° C. Here one takes advantage of the fact that the cooling capacity of Peltier elements can be quickly regulated electrically.

Diode lasers are often cooled and thermostated with Peltier elements in order to keep their emission wavelength and / or efficiency constant. Downstream optical elements of diode and other lasers are often thermostated with Peltier elements.

Peltier elements can be used both for cooling and - if the current direction is reversed - for heating.

Peltier elements are occasionally used as part of CPU coolers. The Peltier element allows the CPU to cool down to temperatures below the temperature inside the case, which either allows the CPU to be overclocked without sacrificing stability, or increases the service life of the processor. The element is installed on the bottom of a heat sink with a fan and supplied with the required power from the power supply unit . To date, however, such solutions have not been implemented due to their additional energy consumption, the electrical energy used is released as waste heat into the interior of the housing.

Photodiodes , e.g. B. for reading scintillators , can be cooled with Peltier elements due to their small area and thus reduce noise and dark current.

Peltier elements are used in diffusion mist chambers to maintain the temperature difference between the bottom and the lid.

The thermal cyclers , which are part of the basic equipment in molecular biology today, use Peltier elements to quickly heat and cool samples, which is necessary, for example, in the polymerase chain reaction .

Peltier elements are sometimes used in small air dehumidifiers . Here, the moist air flows over the cooling element, and the water it contains condenses as it cools down and is collected in a collecting container.

Web links

- www.siteware.ch/peltier : Clear explanation of the thermoelectric effects

- Application example of a Peltier element for CPU cooling

- www.peltier-element.de : Test series on voltage, short-circuit current and power as a function of the temperature difference

Individual evidence

- ^ Peltier basics. Retrieved January 9, 2020 .