Viscometer

A viscometer is a physical measuring device for determining viscosity (resistance of a liquid to forced movement). A statement about the viscosity of a liquid can only be made when a product is set in motion . There are different types of viscometers, which differ in the measuring method. Contrary to the widespread opinion that, in contrast to rheometers, only Newtonian liquids can be measured with viscometers , viscometers are also used for the characterization of non-Newtonian liquids .

Falling body viscometer

This measurement method is based on Stokes' law. The liquid to be measured is located in a measuring cylinder with a radius . With a Höppler falling ball viscometer , a ball with a radius falls through the liquid. Since, when the speed of the ball depends on the viscosity, an equilibrium is established between the gravitational force acting on the ball , the static buoyancy and the frictional force , the ball sinks to the ground at a constant speed.

With Stokes' law it then follows for the dynamic viscosity of the liquid:

- : Density of the sphere

- : Density of the liquid

- : Acceleration due to gravity ( m / s² at the earth's surface)

- : Fall speed

Viscosity measuring cup (Ford cup, flow cup)

In this process, the liquid is poured into a beaker that runs out conically at the bottom into a hole (nozzle) with a precisely known diameter. The viscosity of the liquid can be determined on the basis of the volume of the cup, the nozzle diameter and the measured duration for the liquid to drain. This type of viscosity measurement is described in the standards ASTM D 1200: 1994 and DIN EN ISO 2431: 2011 (withdrawn standards: DIN 53211, DIN EN 535 - October 1996). It was especially used when testing lacquers, paints, resins and liquids with a similar viscosity, especially in the Anglo-Saxon region. Usually the drain time is simply given here as a measure of the viscosity (with reference to the standard and nozzle size). There are also immersion flow cups in which the liquid is withdrawn by dipping the measuring cup so that filling is not required. The quick and easy handling, the inexpensive structure of the measuring instrument (a cup) and the ability to carry out in-process measurements speak in favor of viscosity measurement with the flow cup. However, the method is unsuitable for precise viscosity determinations, since the viscosity range is very limited, the sample quantity is very high and the necessary temperature control is impossible. The viscosity is measured as the flow time in "DINsec".

Engler viscometer

A thermostated precursor version of the flow cup was developed by Carl Engler around 1890 . The viscosity was measured as the flow time in "Engler degrees". It could not prevail either. Since it was an official instrument for the characterization of petroleum, Ubbelohde created extensive tables for converting Engler degrees into viscosities.

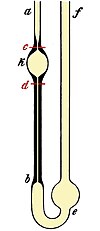

Capillary viscometer

The underlying measuring principle is the flow of the liquid to be measured through a thin tube. A fixed volume of liquid V runs at constant pressure p through a capillary of length l and radius r and the time t required for this is measured. The kinematic viscosity can then be determined by multiplying the time in seconds by the constant of the capillary. Capillary viscometers are z. B. Ostwald , Ubbelohde or Cannon-Fenske capillaries.

According to the Hagen-Poiseuille law , the kinematic viscosity is then proportional to the flow time t:

K is the capillary constant, which only depends on the type of viscometer. K is always specified for commercially available capillary viscometers, e.g. B.

- Flow time 45 s, K = 0.022

- Flow time 85 s, K = 0.011

- Flow time 125 s, K = 0.008.

Then with the dynamic viscosity :

With

- = dynamic viscosity in Pa * s

- = kinematic viscosity in m² / s

- = Density

The capillary viscometer should not be confused with the high pressure capillary rheometer, which is used for the rheometric characterization of highly viscous, non-Newtonian substances.

Rotational viscometer

A rotation viscometer is a physical measuring device which determines the viscosity by means of the deflection of a torsion element (spring rotating element). A distinction is made between different types of viscosity (Newtonian or non-Newtonian). Contrary to the widespread opinion that only Newtonian liquids can be measured with viscometers, viscometers are also used for the characterization of non-Newtonian systems. Rotational viscometers are usually speed or shear rate controlled. The most common methods worldwide are measurements in accordance with ISO 1652 (LV measuring prisms) and ISO 2555 (RV measuring prisms). These measurements are so-called "relative measurements". This means that the measurement is carried out with an undefined gap width between the measuring body (spindle) and the wall of the sample vessel. This principle is also often known as the “Brookfield method”. The advantage of this measurement is the simple, fast and precise test execution and good reproducibility of the results e.g. B. for quality control. By setting different speeds (speed ramps), the user can characterize the flow behavior of his sample (Newtonian or non-Newtonian). In addition to measurement with the standard spindle set, rotary viscometers can be supplemented with various measuring systems for different applications. By using cylindrical measuring systems such as the DIN adapter according to DIN 53019, the small sample adapter, the ultra-low adapter or the Thermosel oven for viscosity measurements at higher temperatures, absolute measurements can also be carried out. With this absolute measurement method, the sample is measured under defined shear conditions, i. H. the measurement takes place using measuring geometries in which the gap width is mathematically defined. This gives the user additional information about the shear stress and the shear rate. The Wells / Brookfield cone-plate viscometer should also be mentioned as a further measuring system, which offers the advantage of working with a very small sample volume under absolute measuring conditions. Special applications and difficult samples, e.g. B. tend to channel formation, test gliding or pastes and substances with particles require the use of viscometers with special measuring bodies. Mention should be made of the Helipath system with T-spindles for non-flowing or poorly flowing samples, cross (Vane) spindles for creep test and determination of the yield point and the spiral adapter for high-viscosity soldering pastes.

Mooney viscosity

This method is very often used to measure the viscosity of rubber and compounds. A standardized method for determining the Mooney viscosity (see DIN 53523) measures the torque of the mixture when the temperature increases (external temperature usually 100 ° C) with the Mooney viscometer. After the appropriate preheating time, the rotor rotates at a constant 2 / min. The rotors used are also standardized in two sizes (L for large 38.1 mm (1.5 inches), S for small 30.5 mm (1.2 inches)) (see DIN 53523). The disk-shaped rotor, 5.55 mm thick, rotates in the center of a chamber with a height of 10.60 mm (27/64 inches) and 50.9 mm (2 inches), the shaft is 11 mm. The shear disk viscometer is a torsional rheometer of the double-sided plate-plate viscometer type. Because of the completely closed test chamber, the flow conditions at the edge of the disk differ greatly from the flow of a pure plate-plate viscometer. This results in a shear rate of about 1.56 1 / s at the edge of the rotor. The torque measured is converted into MU (8.3 Nm = 100 MU). As a result of the measurement, the Mooney viscosity is given as follows:

| Mooney viscosity (M)

8.3 Nm = 100 MU |

used rotor | Preheating interval in min. | Measuring interval in min. | Outside temperature | Viscosity in Mooney units |

| ML (1 + 4/100 ° C) = 76 MU | L = large | 1 min. | 4 min. | 100 ° C | 76 |

| ML (5 + 4/121 ° C) = 68 MU | L = large | 5 min. | 4 min. | 121 ° C | 68 |

|

Shear stress Shear stress |

|

| The Mooney Unit = MU or Mooney Unit = ME can be converted using the standard conversion Torque 84.6 kg cm = 8.3 Nm = 100 MU can be specified. |

|

Process viscometer

Process viscometers are used for the " in situ " measurement of the viscosity in a process plant, e.g. B. in a reactor or in a pipeline. The advantage is that no samples have to be taken.

An elegant method is not to integrate your own measuring device into the process, but to determine the viscosity directly from the torque and the speed of the stirrer drive of a reactor. Suitable stirring drives ( measuring stirrer ) represent the values of an interface available.

Quartz viscometer

With the quartz viscometer, the viscosity is determined by a piezomechanical quartz sensor which is immersed in the measuring liquid. This is characterized by its application possibilities in the area of viscosity measurement at high pressures (up to 10 kbar) and high temperatures (up to over 250 ° C) as well as by its extensive chemical resistance. The oscillation of the quartz is generated by applying a high-frequency electric field and the viscosity is determined from the specific influence of the oscillation behavior by the surrounding measuring liquid. Due to the lack of moving parts, the quartz viscometer is suitable for inline measurements and is also suitable for determining viscosity at high temperatures and high pressures. The measurement, which is based on high shear rates, is independent of the flow form and the quartz viscometer can therefore be installed in any pipeline with any flow.

See also

Web links

Individual evidence

- ↑ Houben-Weyl Methods of Organic Chemistry . 2nd Edition. Volume I: Analytical Methods, Purification. Georg Thieme Verlag, 2014, ISBN 978-3-13-199182-9 , p. 1019 ( books.google.de ).

- ↑ Examples of capillary constants

- ↑ Toni Humar: Mooney viscosity measurements. savatech.eu, accessed September 4, 2016 .

- ↑ M. Pahl, W. Glissle, H.-M. Laun: practical rheology of plastics and elastomers . VDI-Verlag GmbH, Düsseldorf 1995, ISBN 3-18-234192-8 , p. 230 .

- ^ Fritz Röthemeyer, Franz Sommer: Rubber technology: materials, processing, products . Hanser, Munich 2006, ISBN 3-446-40480-5 , pp. 529 ( books.google.de ).

- ↑ Data sheet: Mooney-Viscometer (PDF) on ffinstruments.com, accessed on September 4, 2016.

- ^ Ricardo d'Agostino, Pietro Favia, Francesco Fracassi: Plasma Processing of Polymers . Springer Science & Business Media, 1997, ISBN 0-7923-4859-1 , p. 407 ( books.google.de ).

- ↑ Berthold Bode: Viscometer QVis. (No longer available online.) Archived from the original on January 8, 2015 ; accessed on January 8, 2015 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ WP Mason, M. Hill: Measurement of the viscosity and shear elasticity of liquids by means of a torsionally vibrating crystal. In: Transactions of the ASME (= Journal of Lubricating Technology. Volume 69). 1947, pp. 359-370.

- ↑ Berthold Bode: Fundamentals of quartz viscometry. Retrieved May 2, 2018 .

- ↑ Berthold Bode: Development of a quartz viscometer for measurements at high pressures. Dissertation from the TU Clausthal, 1984.