Salient pole machine

A salient pole machine is a rotating electrical machine that is mostly designed as a three- phase synchronous machine, less often as a single-phase machine, and designed for low speeds. The salient pole machine is one of the largest electrical machines. Due to their design salient pole machines represent a cost-effective version of synchronous machines. This machine type is therefore the most common of all synchronous machines with electrical excitation .

construction

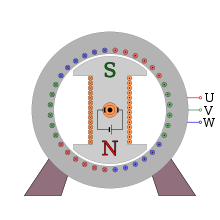

Salient pole machines consist of a stator and a rotor, which together form the main machine. With salient pole machines, a distinction is made between two types, depending on the winding arrangement:

- External pole machines : The structure of the stator of the external pole machine is similar to that of a separately excited DC machine , it contains the magnetic poles or the excitation of the machine. The pole pieces encompass the entire circumference if possible. The three-phase winding is housed in the rotor. The rotor is made of dynamo sheets, the windings are in slots; they are led to the outside via three slip rings . The main current flows through the slip rings.

- Internal pole machines : In the internal pole machine, the stator is constructed in the same way as in the full-pole machine or the asynchronous machine, it carries the three-phase windings in slots of a dynamo sheet package. The magnetic poles for excitation are in the rotor. The rotor is made of solid steel and has pronounced pole pieces on which the excitation winding is located. Because of this structure, it is possible to install a particularly large number of pole pairs. This means that slow-running machines can be built. The rotors of salient pole machines are also referred to as salient pole rotors or pole wheels because of their design . A special design of the internal pole machine is the claw pole machine built into motor vehicles as an alternator . Here the poles are formed using iron claws and the field winding is a single coil in the middle.

The pole coverage ratio is the part of the circumference taken up by the pole pieces and is 0.55 for smaller salient pole rotors and 0.75 for larger machines. A pole coverage ratio that is greater than 0.75 leads to a large pole piece spread.

With larger machines in particular, the internal pole design is more favorable because only the low excitation current can be transmitted via slip rings.

The pole wheels sometimes contain a squirrel-cage cage as in a squirrel-cage motor or an auxiliary winding with which a motor can start (start-up cage) or is used to dampen rotational vibrations (damper cage).

In large salient pole machines, conductors insulated with cross-linked polyethylene have also been used for the stator winding since 1998 . This makes it possible to allow a field strength of up to ten kilovolts per millimeter. These generators can generate high voltage directly , which means that a feed-in transformer is no longer required.

For low speeds, salient pole machines have a correspondingly large number of pole pairs . The number of pole pairs in these machines is at least three and a maximum of 50. These pole pairs require a correspondingly large space. For this reason salient pole machines have a large rotor diameter, which can be over 15 meters. Since the active volume is typical of the performance of the respective machine, the rotor length can be relatively small. Salient pole machines can be operated with a vertical shaft.

Speeds

Salient are mostly for speeds up to 1000 min -1 built. The lowest speed that can be achieved with salient pole machines is 60 min −1 . Corresponding to the speed, salient pole machines are divided into slow- speed machines with speeds of up to 125 min −1 and high- speed machines with speeds greater than 125 min −1 . In the case of hydropower generators, one speaks of high speed only from a speed of 250 min −1 . Higher speeds of over 20,000 min −1 can be achieved with the claw-pole generators typical for alternators in the automotive sector.

Rotor dimensioning

Calculation bases

When designing the rotor, a balanced relationship between armature length and pole pitch is sought. This ratio is between 3 and 4.5 for salient pole machines. The ratio is calculated using the formula:

The maximum rotor diameter is limited by the minimum inertia constant.

This inertia constant is between 1.5 and 3 Ws / VA for slow runners.

Limits

With slow rotors, rotor diameters of over 20 m can be achieved. With large rotor diameters (several meters), however, it is difficult to control the material expansion. Due to the limited mechanical strength of the pole wheel, the rotor peripheral speed is limited to 70 to 90 m / s. Machines of this size can only be assembled on site, as transport as a whole is impossible - the weight of the rotor and its dimensions do not allow this. The 14 generators of the Three Gorges Dam on the Yangtze River in China are among the world's largest salient pole machines . Each generator has a nominal output of 750 MVA at 75 revolutions per minute. The rotors have an outside diameter of 22 meters and each weigh 1,800 tons.

Run-of-river power plant generators

For use in run-of-the-river power plants as low-speed machines, salient pole machines are operated with the shaft in a vertical orientation directly above the Kaplan or Francis turbine . Normally, the guide bearings ( axial bearings ) are arranged above the generator rotor on the shaft, and both the turbine and generator rotor then “hang” on the shaft. This design is particularly common for large generators such as the generators at Hoover Dam .

The umbrella generator is a cheaper and lighter variant, in which there is only one guide bearing between the turbine and the generator and which is therefore similar in structure to an umbrella . Screen generators are used with comparatively lower powers, typically in the range below 30 MVA. The cost savings in the construction result from the fact that only the turbine rotor hangs on the shaft, while the generator rotor stands on the shaft and essentially only exerts pressure forces. This reduces the overall tensile loads on the shaft, which is why the construction can be dimensioned more cost-effectively. The disadvantage of shield generators is the more complex maintenance, since the guide bearing cannot be replaced without dismantling at least the generator rotor.

excitement

The excitation takes place by direct current, the power supply for the rotor takes place via slip rings. The direct current is usually generated by a separate exciter. In some types of machine, the magnetic field is generated by permanent magnets. With direct current excitation, however, better controllability is achieved. In order to determine the excitation current with sufficient accuracy, the magnetization characteristics are required for salient pole machines. These characteristics are determined from the idle characteristic and several stationary load points with pure reactive power output.

Exciter failure protection is essential for large machines .

cooling

There are three cooling options for salient pole machines:

- Air cooling

- Water cooling

- Combined air-water cooling

Due to the less crowded design of the salient pole machine, pure air cooling is often sufficient. However, pure air cooling is only used in smaller machines. In larger machines, the stator is water-cooled. For large machines in the megawatt range, pure water cooling or combined air-water cooling is used. There are also large generators in which both the stator and the rotor are water-cooled.

Operating behavior

Depending on the number of pole pairs , many mechanical north and south poles are formed along the mechanical circumference of the rotor. However, even with an ideal winding, the field distribution deviates more from the sinusoidal shape than is the case with full-pole machines .

Due to the pronounced poles, the machine does not have a constant air gap between rotor and stator, but rather the air gap fluctuates periodically when changing between pole piece and space in the entire machine circumference. In addition, the magnetic resistance R mL of the air gap on the circumference of the rotor is not constant. The magnetic resistance has a minimum in the pole center and a maximum in the pole gap. The different radial air gap distances have an influence on the rotating flow. This is noticeable in that the inductance of a winding L q which is opposite a pole gap is significantly smaller than the inductance L d of a winding which is opposite a pole.

The rotor field of the salient pole machine therefore has a magnetic asymmetry which is very pronounced. Tooth and rotor pole saturation occurs particularly under load. As a result, there are losses in the three-phase windings. These losses are known as lion heart losses (longitudinal field losses). The cause of the lion's heart losses is the tooth relief field. When the load changes, the rotor angle does not remain constant either. In addition, when changing from idling to payload, there is a strong increase in induction - but only on the side of the pole piece on which the torque-generating force acts. Asymmetrical pole pieces mean that the induction is evenly distributed over the entire pole piece and the losses in the three-phase windings are reduced.

Without DC excitation the salient developed the reaction torque M R . With the reaction torque, which makes up around 25% of the total torque of the machine, the machine can be loaded as a motor. As a result of the reaction torque, the overturning moment M K of the salient pole machine occurs. This tilting moment is the maximum torque of the machine, it occurs at a rotor angle that is less than 90 °. The knowledge of the reaction torque is used in the construction of reluctance motors .

use

Salient pole machines can be used as a motor and also as a generator. As a rule, only small machines are used for pure engine operation. Motors with salient pole rotors with outputs of up to ten kilowatts are used in group drives. But there are also machines with outputs of 250 kilowatts, and occasionally machines with up to 40 megawatts output are also used. In some areas of application such as B. in pumped storage power plants , they are used both as a generator and as a motor for pumping operation. The most common use is as a synchronous generator with low-speed drive machines .

Examples of prime movers:

- Piston engines, such as. B. Marine diesel

- Water turbines

- wind turbines

The rotor angle, which is slightly smaller than with full-pole machines, reaches a value of 20 ° to 25 ° in nominal operation.

Unit performance

The performance of salient pole machines has increased more than a hundredfold in 75 years. While in 1903 the largest salient pole machine installed had an output of 6.25 MVA, the output of the generator, which was installed in the Itaipú dam in 1978 , is 824 MVA. After 1978, the sizes of salient pole machines were only slightly increased.

The largest salient pole machine is currently installed in power house No. 3 of the Grand Coulee Dam on the Columbia River . It has an output of 825 MVA and a speed of 85.71 min −1 . The motor-generators used in pumped storage plants have a maximum output of 448 MVA. In most new systems, several medium-sized generators with outputs of up to 300 MVA are installed instead of large individual generators.

literature

- Dierk Schröder: Electric drives - control of drive systems. 3rd edition, Springerverlag, Berlin Heidelberg 2009, ISBN 3-540-89612-0

Individual evidence

- ↑ a b c Günter Boy, Horst Flachmann, Otto Mai: The master's examination in electrical machines and control technology. 4th edition, Vogel Buchverlag, Würzburg, 1983, ISBN 3-8023-0725-9 .

- ↑ a b G. Schenke: Electrical networks and machines. 7. Synchronous machines FB Technik, Dept. E + I ( Memento from December 5, 2013 in the Internet Archive ) (PDF; 406 kB)

- ^ A b c d Hanskarl Eckardt: Basic features of electrical machines. BG Teubner, Stuttgart 1982, ISBN 3-519-06113-9

- ↑ a b Siegfried Heier: Wind power plants, system design, network integration and control. 5th edition, Vieweg + Teubner, Wiesbaden, 2009, ISBN 978-3-8351-0142-5 .

- ^ A b c Rolf Fischer: Electrical machines. 12th edition, Carl Hanser Verlag, Munich and Vienna, 2004, ISBN 3-446-22693-1

- ↑ a b c d Friedhelm Noack: Introduction to electrical energy technology . Carl Hanser Verlag, Munich As 2003, ISBN 3-446-21527-1 .

- ↑ a b A. Senner: Electrical engineering. 4th edition. Verlag Europa-Lehrmittel, 1965

- ↑ Bosch technical briefing on generators. 1st edition, Robert Bosch GmbH, Stuttgart, 1974, VDT-UBE 301/1 De (1.80)

- ^ A b Paul Vaske, Johann Heinrich Riggert: Electrical machines and converters. Part 2 Calculation of electrical machines, 8th revised edition, BG Teubner, Stuttgart 1974, ISBN 3-519-16402-7 .

- ^ Detlev Roseburg: Electrical machines and drives. Fachbuchverlag Leipzig in Carl Hanser Verlag, 1999, ISBN 3-446-21004-0

- ^ A b c d e Franz Moeller, Paul Vaske (ed.): Electrical machines and converters. Part 1 structure, mode of operation and operating behavior, 11th revised edition, BG Teubner, Stuttgart 1970

- ^ Konrad Reif: Automobilelektronik: An introduction for engineers 3rd edition, Vieweg + Teubner Verlag, Wiesbaden, 2009, ISBN 978-3-8348-0446-4

- ^ A b c d Georg Flegel, Karl Birnstiel, Wolfgang Nerreter: Electrical engineering for mechanical engineering and mechatronics . Carl Hanser Verlag, Munich 2009, ISBN 978-3-446-41906-3 .

- ^ A b c d Felix von König: Construction of hydropower plants. Verlag CF Müller GmbH, Karlsruhe 1985, ISBN 3-7880-7249-0

- ^ Chronicle of electrical engineering, VDE. Retrieved September 15, 2012 .

- ↑ Regine Kapfhammer: History of ELIN Weiz , diploma thesis, Der Generatorenbau, chap. 10

- ^ Adolf J. Schwab: Electrical energy systems generation, transport, transmission and distribution of electrical energy. 3rd revised edition, Springer Verlag, Berlin-Heidelberg-Dartredt-London-New York 2012, ISBN 978-3-642-21957-3

- ↑ H. Mrugowsky: Experimental determination of the section characteristics of synchronous machines. In: etzArchiv Vol. 7, 1985, Online ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. (last accessed on March 7, 2013) (PDF file; 2.02 MB)

- ^ Paul Vaske, Johann Heinrich Riggert: Electrical machines and converters. Part 2 Calculation of electrical machines, 8th revised edition, BG Teubner, Stuttgart 1974, ISBN 3-519-16402-7

- ^ Andreas Kremser: Electrical machines and drives, fundamentals, motors and applications. 2nd edition, Teubner Verlag, Stuttgart, 2004, ISBN 3-519-16188-5

- ↑ a b Patent DE10121022A1 07.11.2002: salient pole synchronous machine. Voith Siemens Hydro Power Generation GmbH & Co. KG Online (last accessed on July 1, 2013)

- ^ Hans-Ulrich Giersch, Hans Harthus, Norbert Vogelsang: Testing electrical machines, standardization, power electronics. 5th edition, BG Teubner / GWV Fachverlage GmbH, Wiesbaden, 2003, ISBN 3-519-46821-2 .

- ↑ a b Ekbert Hering, Alois Vogt, Klaus Bressler: Manual of electrical systems and machines. Springer-Verlag, Berlin Heidelberg New York 1999, ISBN 3-540-65184-5 .

- ↑ Erich Hau: Wind turbines, basics, technology, use, economy. 4th completely revised edition, Springer Verlag, Berlin Heidelberg 2003, ISBN 978-3-540-72150-5 .

- ↑ Ali Farschtschi: Electrical equipment in theory and practice. 1st edition, VDE-Verlag GmbH, Berlin and Offenbach 2001, ISBN 3-8007-2563-0

Web links

- H. Mrugowsky: Experimental-analytical determination of the section characteristics of synchronous machines (last accessed on March 7, 2013) (PDF file; 934 kB)