Spark extinction

In electrical switching technology, spark extinction is used when special components prevent the creation of an electrical arc at the switching contacts of each switching component or break it down quickly.

General

Every time a switching contact is opened or an overcurrent protection device melts , an arc is created (colloquially: spark , a channel that is conductive due to gas ionization). This can reach temperatures of several thousand degrees Celsius and lead to thermal destruction of the electrical conductors and neighboring insulation material.

The arc damages the contact surfaces and in the worst case can lead to contacts being welded together. The switch “sticks” and can no longer be separated. Sparking is also responsible for the erosion of the contacts and thus reduces the service life of a component.

The higher the current intensity and / or the voltage , the more energetic the resulting arc. With direct current , spark quenching is even more important, as there is no zero voltage crossing, as with alternating current , which can extinguish the arc by itself.

The function of spark quenching is based on the fact that the arc is artificially lengthened and thus cooled or the ionized gas layers are removed from the switching area using a suitable device and the arc is practically blown out. This can be done in a number of ways. With the geometric shape of the switching elements, it is possible to specify the direction of the arc. The arc can be accelerated with the help of thermals or a magnetic field ( blow magnet ). It is also possible to blow away the arc with compressed gas. Another possibility is to switch the switching process under oil or under protective gas such as. B. sulfur hexafluoride (SF 6 ). Also vacuum hinders the formation of arcs. For higher power fuses, sand is used, which is melted by the arc and forms an insulating glass plug.

Extinguishing switching arcs

When quenching switching arcs, a distinction is made between the methods of spark quenching according to the level of voltage.

Low voltage area

When switching low power and alternating voltage, the switching arc extinguishes automatically at low currents at the next zero crossing of the alternating voltage (e.g. power switch on devices or light switches and cam switches on electric cookers and machines).

In particular with direct voltage and currents from about 1 A and voltages from about 50 V, switching arcs and the like go out. The ionization of the isolating gap can become so strong even with 50 Hz AC mains voltage with large currents that it is sufficient to re-ignite the arc after a zero crossing, especially if the contacts are not far enough apart at this moment are. Attempts are therefore made to construct switches in such a way that the contacts move away from one another as quickly as possible using a spring . This type of contact is also known as a snap contact.

The energy stored in inductive loads can, if possible, be kept away from the switching contacts by briefly diverting the current flow during the switching process. The diversion can be done with a freewheeling diode with direct voltage, with a Boucherot element for alternating voltage or in simple cases only with a capacitor or a surge arrester ( varistor or suppressor diode ). For details, see protective circuit .

Also in parallel, but later than the main contacts open switch contacts can the flow of current or arc assume (eg in. Hart Gas - disconnectors or the contacting Hornableiter at counters of the tram - catenary ). With hard gas switches, this delayed opening contact runs in a chamber made of a material ("hard gas") which, when heated, emits gases that hinder the ionization or allow it to subside more quickly.

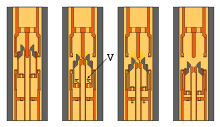

With horn arresters, the switching arc runs out of the area of the contacts in the direction of the expanding horns due to its own magnetic field, thereby increasing its length and, if necessary , extinguishing it by additional cooling with sheet metal or ceramic parts, the so-called deion chamber for arc quenching . This is z. B. used in contactors or circuit breakers in the low voltage range. With horn conductors that widen upwards, such as the Jacob's ladder , the thermal lift of the arch also contributes to its movement.

High voltage area

Arc quenching measures must quench the switching arc as quickly as possible in order to avoid damage to the contacts and insulating materials. This can be done by greatly increasing the length of the arc's path. Switch disconnectors and circuit breakers for high voltages based on this principle work with compressed air , which blows away the ionized air (arc). Another measure is the generation of a magnetic field with a blow magnet , which can also be designed in the form of a coil and through which the load current flows: the magnetic field deflects the switching arc, increases its length and extinguishes it.

Encapsulated switchgear systems are also used: encapsulating the contacts prevents air in the area of the contacts. Instead of air, there is a vacuum in the area of the contacts . Vacuum circuit-breakers are mainly used in medium-voltage networks with voltages from 5 kV to 30 kV with frequent switch inserts and are practically maintenance-free.

In addition to vacuum is used in circuit breakers and sulfur hexafluoride (SF 6 ) as the quenching gas used. Because of its very inert properties and a dielectric strength that is almost three times higher than that of air , SF 6 can be used to effectively reduce and interrupt switching arcs. The use of SF 6 , in combination with high pressure to reduce ionization, takes place in completely encapsulated switchgear such as self-blowing switches , which are designed for voltages from 6 kV to 1 MV. However, SF 6 is also the strongest known greenhouse gas , its global warming potential is around 22,800 times that of carbon dioxide (CO 2 ). However, the quantities released during production and maintenance are relatively small and therefore of little relevance to the greenhouse effect.

The quenching of the switching arc in oil switches is based on the effect that part of the oil in the area of the arc is chemically decomposed. The switching chamber and the switching contacts are completely under oil in an airtight housing. The arc creates hydrogen gas in the oil at high gas pressure and with very high thermal conductivity , which extracts heat from the arc and thus, in addition to the electrically insulating properties of the oil, leads to extinction. As a consumable, the oil must be constantly renewed and the decomposition products and impurities in the oil that arise during the switching processes must be removed. Oil switches have been replaced by more maintenance-friendly and electrically more powerful SF 6 switches since the mid-1970s .