Steinmetz circuit

The Steinmetz circuit , named after Charles P. Steinmetz , is an electrical circuit for operating three-phase asynchronous motors on a single-phase alternating current network. The circuit is only used for smaller three-phase asynchronous machines with squirrel cage rotors up to 2 kW .

Basics

In order for the rotor to rotate in a three-phase motor , the stator must be supplied with alternating current . Normally, the three outer conductors in the stator generate a rotating field that is created by the 120 ° phase shift between the outer conductor alternating voltages. If an outer conductor fails or if only a single-phase AC voltage is available (for example a household socket), the motor cannot start on its own; it would have to be started by hand. With the Steinmetz circuit, a three-phase asynchronous motor can still start up automatically in this case. However, the torque and power are lower.

The operating capacitor in the Steinmetz circuit

For the Steinmetz connection, a star or delta connection must be made, depending on the nominal voltage of the motor , to match the existing mains voltage. In Europe this is usually 230 V. A metal-paper capacitor or a polypropylene film capacitor with self-healing properties is common as the operating capacitor , which is connected from one of the two feeding terminals to the third free terminal, depending on the desired direction of rotation. The size of the capacitance depends on the motor power as well as on the operating voltage of the motor. With reference to DIN 48501, which was withdrawn years ago, a guideline value of approx. 70 µF per 1 kW motor output for an operating voltage of 230 V is recommended in various specialist books and forums. The general formula for calculating the operating capacitor with the capacitance C and a power P of the electric motor at the nominal voltage U is:

- with angular frequency

- Source:

- with angular frequency

An auxiliary phase is generated by the capacitor. However, instead of 120 °, this only has a phase shift of less than 90 °. So only an elliptical rotating field is generated, which is sufficient to specify a direction of rotation for the motor so that it starts up automatically. However, as a result, the motor also has a wavy torque curve and, depending on the required torque, humming noises occur with twice the mains frequency. The capacitor and the coil of the motor together form a series resonant circuit . During operation, the voltage across the capacitor is therefore higher than the mains voltage. As with the capacitor motor, it should be designed for 400… 450 V alternating voltage so that it is not destroyed. Due to the capacitor, the currents in the individual strings are different. The starting current of the motor depends on the required torque and is a multiple of the nominal current. Since the operation of larger motors results in increased single-phase loads on the network, the operation of motors with Steinmetz circuit is limited to 1.5 kW depending on the supplier.

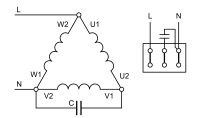

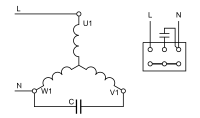

Circuit examples

With the Steinmetz circuit, the motor can be operated in a triangle or a star, depending on the coil voltage. The delta connection is preferred.

Torque and power

The starting torque of a motor in Steinmetz circuit is significantly lower than that of three-phase motors that are supplied with real three-phase current. Depending on the size of the operating capacitor is the starting torque M A of between 20% and 50% - at an average of about 30% - of the nominal torque M N .

If the required starting torque is higher, a starting capacitor C A can be connected in parallel with the operating capacitor C B during start-up . The capacitance of the starting capacitor can be twice as high as the capacitance of the operating capacitor. After starting up, the starting capacitor must be switched off, for example using a centrifugal switch or time relay, as otherwise the motor winding would overheat. The starting capacitor allows the tightening torque to be increased to almost 100%. As a rule, it is dimensioned so that the starting torque is 90%.

Three-phase motors in Steinmetz circuit are not suitable for heavy starting due to the weakened starting torque, even with a starting capacitor . Starting capacitors are mostly bipolar electrolytic capacitors and only suitable for short-term operation.

The output of a three-phase motor operated in a Steinmetz circuit is around 80% of the rated motor output.

Application of the Steinmetz circuit

The Steinmetz circuit is suitable for applications without a three-phase current connection or for machines in which you want to keep the direction of rotation safely without having a capacitor motor available. The disadvantage of the Steinmetz circuit is that the torque , especially the starting torque, is lower. To get the same performance you have to use a bigger motor. Like the capacitor motor, the Steinmetz circuit is limited to drives with an output of up to around two kilowatts for economic reasons . The operating capacitor is a significant cost factor in larger motors and also a source of unreliability.

With the advent of three-phase frequency converters , the area of application was further restricted, because they can generate the three-phase three-phase current required for a three-phase motor from a direct or alternating voltage. This means that it is possible to operate a three-phase motor on single-phase AC voltage without any restrictions.

The Steinmetz circuit is sometimes used to drive concrete mixers , fans, feed mixers, older washing machines and circulation pumps in heating systems. Older washing machines used pole-changing motors for the wash and spin cycle. That was partly solved in such a way that the z. B. executed sixteen-pole winding used for washing three-strand, but the powerful two-pole centrifugal winding two-strand. The already necessary large capacitor could then be used both for washing (Steinmetz circuit) and for spinning (capacitor motor).

Individual evidence

- ^ A b Hans-Dieter Stölting, Achim Beisse: Small electrical machines. BG Teubner Verlag, Stuttgart 1987, ISBN 978-3-519-06321-6 , pp. 20, 30-31, 70-72.

- ↑ a b c d e f Günter Springer: Electrical engineering. 18th edition, Verlag Europa-Lehrmittel, 1989, ISBN 3-8085-3018-9 , p. 295.

- ↑ a b c Franz Moeller, Paul Vaske (ed.): Electrical machines and converters . Part 1 structure, mode of operation and operating behavior, 11th revised edition, BG Teubner, Stuttgart 1970, pp. 152, 156–158.

- ↑ a b c d e Klaus Tkotz, Peter Bastian, Horst Bumiller and others: Electrical engineering. 27th revised and expanded edition. Verlag Europa-Lehrmittel Nourney Vollmer GmbH & Co. KG, Haan-Gruiten 2009, ISBN 978-3-8085-3188-4 , p. 457.

- ↑ Wilfried Plaßmann, Detlef Schulz (ed.): Handbook of electrical engineering. 5th corrected edition, Vieweg + Teubner GWV Fachverlage GmbH, Wiesbaden 2009, ISBN 978-3-8348-0470-9 , pp. 834-835.

- ↑ a b Rolf Fischer, Hermann Linse: Electrical engineering for mechanical engineers . 10th edition, Vieweg + Teubner Fachverlage GmbH, Wiesbaden 2000, ISBN 978-3-519-26325-8 , p. 273.

- ↑ Hans-Jürgen Bederke, Robert Ptassek, Georg Rothenbach, Paul Vaske, Heinrisch Frohne (eds.): Moeller guidelines for electrical engineering . Volume VIII, Electrical Drives and Controls, 2nd revised edition, BG Teubner Verlag, Stuttgart 1975, p. 27.

- ↑ Motor capacitors (accessed November 2, 2017)

- ↑ a b Andreas Kremser: Electrical machines and drives. Basics - engines and applications. 2nd edition, BG Teubner Verlag, Stuttgart 2004, ISBN 3-519-16188-5 , pp. 128-132.

- ^ Nolle E .: Manuscript for the lecture: Electrical machines (parts 1 and 2). (PDF; 1.9 MB) University of Esslingen; Faculty: Mechatronics and Electrical Engineering, 2007, p. 74 , accessed on September 14, 2013 (Section 3.6.2.6 Steinmetz circuit).

- ↑ a b E. Nolle, A. Beshta: Electrical machines and drives. National Mining University of Ukraine, Dnipropetrovsk 2013, ISBN 978-966-350-418-6 , pp. 84–85.

- ↑ Otto Weidling: The electric motor for the machine tool. Published by Julius Springer, Berlin 1935, p. 35.

- ^ A. Senner: Electrical engineering. 4th edition. Verlag Europa-Lehrmittel, 1965, p. 210.

- ↑ Information from Amelec Electronic on the Steinmetz circuit . (accessed on November 7, 2017).

- ↑ a b c d Ernst Hörnemann, Heinrich Hübscher: Electrical engineering specialist training in industrial electronics. 1st edition. Westermann Schulbuchverlag GmbH, Braunschweig, 1998, ISBN 3-14-221730-4 .

- ↑ Drive technology Carl Rehduss spur gears, spur gear motors . P. 2/2, (accessed on November 9, 2017).

- ^ A b Günter Boy, Horst Flachmann, Otto Mai: The master's degree in electrical machines and control technology. 4th edition, Vogel Buchverlag, Würzburg, 1983, ISBN 3-8023-0725-9 , pp. 160-161.

- ↑ Data sheet motor capacitors from Conis. Page 15, (accessed Nov. 7, 2017).

- ^ Wilhelm Hille: Expertise for electrical professions. 7th revised edition, Springer Fachmedien, Wiesbaden 1983, ISBN 978-3-519-46800-4 , p. 251.

- ^ Hans-Ulrich Giersch, Hans Harthus, Norbert Vogelsang: Electrical engineering for technical schools. Electrical machines with an introduction to power electronics, 4th revised edition, Springer Fachmedien, Wiesbaden 1998, ISBN 978-3-322-92707-1 , p. 321.

- ↑ J. Stepina: The single-phase asynchronous motors: structure, theory and calculation , Springer-Verlag 2013, 216 pages, page 104.

- ↑ Type plate and measurement on a pole-changing washing machine motor.

Remarks

- ↑ The overvoltage depends on the speed and load. For this reason, the capacitor voltage U C is set to 1.2 times the mains voltage. (Source: Franz Moeller, Paul Vaske (Ed.): Electrical machines and converters .)

- ↑ In the past, power supply companies allowed AC motor outputs of up to 3 kW. (Source: Ernst Hörnemann, Heinrich Hübscher: Electrical engineering specialist training in industrial electronics .)