Troop parachute PD-47

The PD-47 troop parachute ( Russian парашют десантный, образца 1947 ) was the first parachute developed in the Soviet Union after the Second World War . With its distinctive square parachute canopy, it was used successfully in the Soviet Union and many countries in Eastern Europe, sometimes well into the 1970s. In the GDR he was a training and parachute parachute for the air forces , paratroopers , combat swimmers , long-range and special reconnaissance officers, the Society for Sport and Technology and the Ministry for State Security .

development

In 1946, the Scientific-Experimental Institute for Airborne Systems ( Russian ниэи Пдс ) was founded in Moscow under the direction of Fedor D. Tkachev. It was responsible for the development of all parachute and airborne technology for the military and space travel of the Soviet Union. Since the early 30s, the Soviet Union, which at that time had already set up large paratroopers' associations and also made skydiving possible for interested civilians, developed various parachutes. These included models with a round and a square parachute canopy. In 1947, the PD-47 parachute was developed at the Moscow Institute of NA Lobanov, MA Alekseev and AI Sigaev, and a year later it was introduced by the military.

The development of a new parachute became necessary because the minimum and thus the lowering speed of the transport aircraft of the time was constantly increasing. With the previous parachutes it was possible to lower the aircraft at a maximum flight speed of 200 km / h. At higher speeds, the suspension lines or the canopy were damaged and the likelihood of suspension lines being thrown over or other incorrect openings increased significantly. Furthermore, the strong development push could injure the jumpers. In order to be able to jump up to a landing speed of 300 km / h in the future, design changes had to be made, which were incorporated into the development of the PD-47.

The PD-47 is mainly based on the MPLK-45 rescue parachute from 1945, which was developed for pilots and aircraft crews, which was also square in shape and produced little propulsion by the same principle. Tried and tested harnesses were also used, which hardly differed from the parachutes used up to then. With the exception of the round dome, the PD-47 also had many similarities with the parachute D-1, which was partly used in parallel.

construction

The PD-47-5 described below (also referred to as PD-47 Series 5) was the first important further development compared to the original model and was introduced around 1960. It differed from its predecessors primarily in terms of the auxiliary parachute, the way the automatic opening device was carried and the additional bag in the bag. These changes should make the opening process even more reliable. In addition, the inside of the packing cover lacked the possibility of looping the suspension lines without using a delay bag. Early versions of the PD-47 still had this, which also enabled automatic jumps without a delay bag and thus at lower dropping heights. Subsequent versions such as the PD-47-7 differed from the PD-47-5 mainly in the 4.5 m long connecting line between the parachute canopy and the delay bag. However, the PD-47 was also further modified and improved in the exporting countries, where some of them were produced under license.

The PD-47 consists of the parachute canopy with the suspension lines, the harness, the pack cover with the flexible protective tubes, the delay bag, the auxiliary parachute with spring mechanism, the pull-up line, the protective cover for the pull-up line, two connecting lines, a parachute passport and a carrying bag.

Main parachute

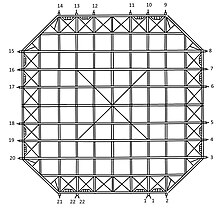

As has been the case for many years, the designers have used cotton in the weave of percale or batiste as the material for the PD-47 . The reason for this was the limited availability of expensive natural silk and the development of suitable synthetic fibers that was not yet completed at that time . The main parachute had a square basic shape with cut corners and consisted of a checkerboard pattern with adjacent square fields. Depending on the size of the fields, the parachute was made of eight or ten sections in one lane. The size of the two production models differed only slightly. The base of the eight-part version was 69 m² with dimensions of 8.60 × 8.53 m and the base of the ten-part version with the dimensions of 8.90 × 8.47 m measured 71 m². Between the fields, the parachute canopy was reinforced with 13 mm wide strips of fabric. The outer fields at the base edge and the middle of the canopy were additionally reinforced with a sewn-on fabric cross in order to distribute the forces that occur evenly over the parachute when the parachute is deployed. At the base edge, which had also been reinforced with 25 mm wide cotton strips, 16 small pockets were sewn into which the air caught during the unfolding process and thus accelerated the opening of the parachute.

The 24 cotton suspension lines had a uniform length of 6.5 m and were sewn directly to the base edge. Because the corners of the ten-part canopy variant, which were bevelled at 45 °, ran over two fields instead of one, there were only 24 suspension lines here too, despite the additional fields. The middle one was missing on each side and the two adjacent lines were also missing at the rear. So so-called keels were created on the side alone, the rear keel being significantly larger and the main part of the air escaping here. In contrast to the round canopies of other parachute designs, the PD-47 did not have a crown opening in the center of the parachute. Due to the keels, the PD-47 generated a slight forward speed of 1.5 to 2.0 m / s. In order to stabilize the rear section of the parachute somewhat, the two suspension lines next to the keel were doubled. The suspension lines ran in groups of six to the four D-rings of the main risers.

Harness and packing case

The PD-47 harness is made of 44 mm wide nylon straps and has a chest and two leg hooks. The reserve parachute was attached with two snap hooks at stomach level and the carrying straps of the reserve parachute were attached to two other fasteners at the level of the chest strap. The automatic activation device was mounted in the early versions below the right shoulder blade in a back brace. From there, a hose, through which the pull wire of the opening machine ran protected, went over the upper flap to the closures of the packing envelope. A second tube ran from the bag to the left front of the harness, where the handle for the manual parachute opening was tucked into a small pocket. The PD-47-5 also had a third short tube through which the end of the pull-up line was passed for automatic parachute opening. This meant that the locking pins could always be pulled straight up, regardless of the position in which the jumper fell.

The packing cover, reinforced with a wire frame, consisted of four flaps which were closed on three pin-and-eye closures with a pin each. Depending on the chosen opening variant, the parachute was packed in such a way that the pegs could be pulled out by the jumper, the automatic opening device, the pull-up line or a combination thereof. Basically, the jumper's opening handle was always connected to the pull cable - even with an automatic jump. If the snap hook was not yet or not correctly hooked into the aircraft, it could open the main parachute independently. The pin closures are covered with a flap after the packing process to prevent them from getting stuck and unintentional triggering. The PD-47-5 had a pocket for the automatic opening device on the lower right-hand side of the bag. As soon as the pegs were pulled out, the packing sleeve opened, supported by a total of eight elastic bands that were tensioned, and released the delay bag and, if necessary, the auxiliary parachute. In the further development of the PD-47-5, the lower section of the suspension lines was looped into the lower flap of the packing envelope for the first time and fixed with two small flaps on the side. With the opening process delayed in this way, the stabilizing moment of the opened auxiliary parachute should be used longer on a possibly spinning jumper and the deployment should be more reliable.

Opening introductions

The pull cord of the PD-47 had to perform various tasks. On the one hand, it should unlock the automatic opening device when jumping free-fall by pulling out the locking pin when jumping. On the other hand, the pull-up line could open the parachute immediately when jumping. It was provided with two loops for this purpose. The first loop was connected to the locking pins of the packing bag. The second loop was firmly connected to the deceleration bag and through its open tip with a thin cord to the apex of the parachute canopy. When jumping, the packing bag was opened first, then the deceleration bag unfolded and the parachute canopy was torn from the line as soon as the suspension lines were fully stretched. If the packing cover was to be opened by the pull cord, it also had a flexible fabric cover at the lower end, which slid over the locking pins and thus protected the aircraft from damage. The opening handle in the pocket on the harness was always attached to both free fall and automatic jumps. It was also connected to all three locking pins by a pull wire in the protective cable hose.

For free-fall jumps, the pull wire of the opening machine was attached to the pull wire of the opening handle for the jumper in front of the first locking pin. Opening machines had been developed before the introduction of the PD-47 in the Soviet Union. Both the PPD-10U and the KAP-3 were used, with the latter being the most common in various versions. It had two setting options. On the one hand, the free fall time could be set in one-second steps up to a maximum of 5 seconds. On the other hand, a barometric altimeter was built in, with which the opening height could be adjusted. As soon as the automatic opening device was triggered, the built-in spring pulled on the wire and opened the packing cover. The set opening height always referred to the sea level at normal pressure. The settings therefore had to be adjusted depending on the low or high pressure weather conditions and the altitude of the landing site. In contrast to modern digital successors, the KAP-3 could not measure the rate of descent and thus always triggered, even if the jumper had already opened the parachute. To check the clockwork and the altimeter, the machines had to be tested regularly in a vacuum chamber.

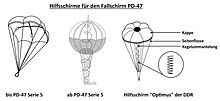

With the PD-47, various auxiliary parachutes have been used over the years to initiate opening. At first there were simple parachutes with eight or more suspension lines, which could not or only slowly unfold due to an unfavorable body position of the jumper when the flow was poor. In addition, the suspension lines could easily get caught on the jumper or on equipment carried along. That is why spherical auxiliary screens with internal helical springs were introduced with the PD-47-5. The upper hemisphere was made of orange nylon fabric and had an area of 0.22 m². The lower hemisphere was made of mesh fabric, followed by a cone with a loop to attach it to the delay bag. This, too, was made of mesh and allowed the air to flow into the upper hemisphere. The entire cone and the ball ran through the spring and the outer spoke frame of the auxiliary umbrella was also made of flexible spring steel. In this way, the auxiliary parachute could be stowed flat in the bag during the packing process.

The cotton delay bag ensured a controlled and slower parachute deployment during automatic and free fall jumps. The PD-47 was the first extensively introduced parachute with a deceleration bag in the Soviet Union. With it, the many cases of torn suspension lines, legs caught in the suspension lines or suspension lines thrown over the parachute canopy could be drastically reduced. He also slowed down the parachute deployment and thus reduced the forces acting on the jumper and the parachute. The deceleration bag was a 4.1 m long tube to the tip of which the parachute or the pull-up line was attached. As soon as the packing bag was open and the delay bag was pulled into the airflow and stretched, the suspension lines attached to it loosened, opening the bag of the delay bag and freeing the main parachute. Because the suspension lines and the parachute canopy were stretched first before the parachute fully unfolded, the opening had become much more reliable. If the jumper turned or spun in an uncontrolled manner during the deployment process, the deceleration sack produced a stabilizing force for a brief but decisive moment before the parachute opened fully. These characteristics made the PD-47 a reliable and popular parachute.

It was only in the 1960s that a connecting line connected the main parachute and the deceleration bag with each other even after the deployment. Until then, it fell to the ground separately, which is why it was colored orange to make it easier to find it.

use

The PD-47 was introduced as a uniform training and troop parachute for jumps from tethered balloons and airplanes with manual and automatic opening for all parachute users at the time. The following three opening variants were possible for the different types of jump:

- Freefall jump with automatic opening device, which was activated by pulling out the safety pin from the pull-up rope when jumping. After the set time or the specified opening height, the automatic opening device opened the packing envelope and released the auxiliary parachute with the delay bag. At the same time, the jumper had to count the ordered free fall time and then pull the handle, which also led to the opening of the bag.

- Automatic jump with a pull-up cord, which opened the packing cover directly when jumping by pulling out the three locking pins. This released the auxiliary parachute and initiated the parachute opening.

- Automatic jump, with the pull-up line firmly connected to the deceleration bag without an auxiliary parachute. The two-part pull-up rope first opened the packing cover when jumping and then pulled out the delay bag. The thin connecting cord broke and the jumper sank to the ground on the open parachute, while the deceleration bag got stuck on the pull-up line.

The last variant was mostly used when jumping out of a tethered balloon , because the parachute opened the fastest and with the least loss of height. For jumps from an airplane, the drop-off speed was limited to 300 km / h. The maximum jump weight was 120 kg and thus the PD-47 had a maximum sink rate of 5.2 m / s near the ground. With automatic parachute opening without an auxiliary parachute, it was possible to jump from balloons floating 400 m above the ground and from 120 m high and 180 km / h flying airplanes. Training jumps were, however, generally not carried out lower than 250 m dropping height. In order to be able to control the PD-47 precisely, it took some experience and a lot of strength. It was steered by pulling the front suspension lines down left or right, with the jumper pulling left to turn right and vice versa.

The parachutes were particularly sensitive to UV rays and moisture because of the cotton used . In well-ventilated storage locations, they could be stored in the packed state for up to 14 days at a humidity of 40 to 70% and temperatures of 0 to 30 ° C. If the PD-47 was not packaged, it could be stored under the same conditions for up to 3 months. Particular attention had to be paid to the humidity, because the cotton fabric quickly began to get mold stains and become moldy. Like UV rays, this greatly reduced the mechanical strength and the parachute had to be laboriously repaired or scrapped. The maximum useful life was 10 years.

Various patterns with square or round parachute canopies have been used as reserve parachutes over the years. In the Soviet Union, the PS-47 and PS-41 were mainly used in the first few years and were worn upright on the chest. Later it was mainly the reserve parachutes PS-41a, S-1P and S-2, as well as their licensed products in other countries. They were worn across the chest in order to reduce the number of knocked out teeth and chapped lips on the previously high edge of the reserve parachute.

use

After the Second World War, the Soviet Union supported the establishment of the armies in the Warsaw signatory states with material and personnel help and also delivered the PD-47 parachute to many countries. As early as 1953, for example, Czechoslovakia resumed parachute training with the PD-47. Other users were the armies of Hungary , Poland , Bulgaria and the GDR.

Soviet Union

The PD-47 was the most widely used jump parachute by civil and military users until the mid-1950s. As a troop parachute, it was used by paratroopers and the specialized units of all branches of the armed forces and various intelligence services that received parachute training. In 1948 the PD-47 was introduced into the armed forces and in the same year 67,325 jumps were made with it, 12 of which resulted in a fatal jump accident.

In the Soviet Union, the pilots of the air forces also completed their compulsory jumps with the PD-47, which was customary for regular preparation for emergency situations. Therefore, the fighter jet pilot and first man in space, Yuri Gagarin, jumped with the PD-47 for this purpose. Because of the inaccessible Russian expanse, the fire jumpers also used the PD-47 to be able to jump close to the fire for quick fire fighting. Since the 1930s, young men and women in the Soviet Union have been able to practice parachuting. After the Second World War, the PD-47 was also used for pre-military training and sport jumping at the DOSAAF (German: Voluntary Society to Support the Army, Air Force and Fleet) under the leadership of the armed forces. The PD-47 was used in the DOSAAF until the 1970s - sometimes with wide red and blue stripes on the parachute canopy.

In the paratrooper associations, the D-1 parachute replaced the PD-47 from 1955. It had a round parachute canopy, but was otherwise identical to the PD-47-5. For military use, the PD-47 could no longer be used due to the lack of a stabilization device from the late 1950s at the latest, when the drop-off aircraft were flying faster and faster. The stabilization device was tested with the PDPS-48, which was also based on the PD-47, in order to brake the jumper to a safe opening speed for the main parachute with a stabilization parachute after an airplane flying over 300 km / h took off and to stabilize him in the process .

German Democratic Republic

In the GDR, the first parachute jumps were carried out with the PD-47 in the 1950s. Following the example of the DOSAAF, the Society for Sport and Technology (GST) was founded in the GDR , which began early with parachute jump training. In 1956 the GST carried out the first parachute jumps from Soviet Li-2 aircraft using imported PD-47s. The PD-47 remained the training parachute in the GST until the 1970s and was replaced by the self-developed RS-4 / 3C parachute.

With the establishment of an army in the GDR, the air force became the first military user of parachutes. The PD-47 was used for the compulsory jumps of the pilots and parachute packers until the late 1960s. With the establishment of a paratrooper battalion and jumping reconnaissance units in the National People's Army (NVA), the PD-47 also came to the land forces. The first paratroopers began parachuting training in 1961. At that time, however, the PD-47 no longer allowed jumps from the high-speed Soviet transport aircraft, so that the in-house developments of the RS-4 series replaced the PD-47 in the jumping units from 1966. The PD-47s used in the GDR were models of the early variants with square spring auxiliary parachutes and suspension lines and the possibility of jumping without a delay bag.

From the late 1950s, the GDR had the PD-47 produced under license by VEB Bekleidungswerke Seifhennersdorf (BEWES). The parachutes of the Wehrmacht were already being made there during the Second World War . The PD-47s produced in the GDR all had eight lengths and were made of cotton batiste with a natural silk content of 50%. Because they were originally only intended for training jumps without equipment or weapons, the canopy reinforcements had been reduced. Therefore jumpers with a body weight of 90 kg or more were no longer allowed to carry additional equipment with them when jumping with the PD-47.

In the GDR in the 1950s, a synthetic fiber similar to nylon was developed with the name Dederon . In order to be able to use this light and resistant synthetic fiber in parachute construction, a slightly modified PD-47 made of this material with the designation RS-1 was developed and tested. However, the thermal loads caused by pulling the deceleration bag down from the parachute canopy were too great and resulted in damage. Only later could the finishing of the Dederon fibers be improved so that they could withstand these loads. But in 1962 it was possible to replace the thick suspension lines made of the cotton blend with lighter, thinner and nevertheless more tensile suspension lines made of Dederon and to deliver them to the troops with the parachutes under the designation PD-47D. The thinner suspension lines made it easier to pack the parachute, but also made it difficult to pull it down for steering because of its smoother surface.

In the NVA, the paratroopers were trained with the PD-47 in free fall of up to 10 seconds. Without a stabilization parachute, after a few automatic jumps, they jumped in free fall with increasing freefall times. The parachutists often had great difficulty finding a stable free-fall position, which made the reserve parachute, which was carried loosely in front of the chest, even more difficult. In this situation, the deployment of the auxiliary parachute was hindered and its suspension lines sometimes got caught on the jumper or the equipment. In order to solve this problem, the independently developed spring aid “Optimus” was used. This had a cylindrical shape with an internal helical spring and was made from a mixture of air-permeable and air-impermeable fabric on top.

One of the great things about the PD-47 was its controllability. During night jumps, however, the built-in feed system regularly led to collisions between jumpers, which were potentially very dangerous, due to poor visibility and the sluggish control. With the aim of eliminating this danger, a version of the PD-47 without feed was produced in Seifhennersdorf. In the modification known as PD-47 oK (without keel), only one suspension line was missing on each side and the large rear keel was closed in this way. The neutral sinking of the PD-47 oK also reduced the pendulum stability, so that part of the PD-47 was only exchanged for use during night jumps from 1964 onwards. In the early years all PD-47s were made of white material. Only later were parachute canopies delivered in a dark color and a few dozen with a multicolored stain camouflage print. The PS-47 and PS-41a were initially used as reserve parachutes in the GDR and later the BE-3 made of natural silk, which was developed from the PS-41a in the GDR, and from 1964 the BE-3D, which was made entirely of Dederon. The KAP-3 was used throughout as the automatic opening device.

Technical specifications

| Parameter | PD-47 |

|---|---|

| Cap shape: | Square with bevelled corners |

| Cap area: | 69 m² for eight and 71.5 m² for ten lanes |

| Max. Set down speed with immediate opening: | 300 km / h |

| Max jumping weight: | 120 kg |

| Sink speed with max. Jumping weight: | 5.2 m / s |

| Max. Opening time: | 4 s |

| Feed speed: | 1.5 - 2 m / s |

| Number of suspension lines: | 24 |

| Length of the suspension lines: | 6.5 m |

| Weight of main parachute and harness: | 16.4 kg |

| Packing cycle: | 14 days |

literature

- AM Lukin: Parachuting of the NVA. 1st edition, Society for Sport and Technology - Central Board, Halle (Saale) 1954.

- (Ed.) Head of the administration of the Air Force: construction and operation of parachutes - instructions for combat units and colleges of the Air Force (original: . УСТРОЙСТВО И ЭКСПЛУАТАЦИЯ ПАРАШЮТОВ - УЧЕБНОЕ ПОСОБИЕ ДЛЯ СТРОЕВЫХ ЧАСТЕЙ И УЧИЛИЩ ВВС ) Military publishing house of the Ministry of Defense of the USSR, Moscow 1955.

- Günter Schmitt: The technique and theory of the parachute jump. Society for Sport and Technology - Central Board, Berlin approx. 1956.

- Manual: Specifications and instructions for packing and performing jump training with the PD-47-5 (original: Техническое описаниеи инструкция по укладке и эксплуатацииии тренировотач3 .Пога 47 .

- Gerhard Leutert: Paratroopers of the NVA. 1st edition, Steffen Verlag, Friedland 2012, ISBN 978-3-942477-23-9 .

Individual evidence

- ^ History of the institute . Website of the Russian Parachute Institute. Retrieved January 5, 2015.

- ↑ Military Paratroopers Association of Slovakia (Ed.): Red Berets. Volume VII. No. 4, Bratislava, October 31, 2007, p. 8.

- ↑ Boris Kostin: Margelov ( Маргелов. ) Junge Garde, Moscow 2005, ISBN 5-235-02846-5 .

- ↑ Vladislav Artemov: Yuri Gagarin - a living legend (original: Юрий Гагарин - человек-легенда. ) OLMA Media Group, 2011.

- ↑ RA Stasevich, GI Filinov: Information manual for parachutists (original: СПРАВОЧНОЕ ПОСОБИЕ ПАРАШЮТИСТУ ), military publisher of the Ministry of Defense of the USSR, Moscow 1959, p. 76.

- ↑ Gudrun Pistiak: At 160 kilometers an hour towards the earth. In: Fliegerkalender der DDR 1987. Military publishing house of the German Democratic Republic, Berlin 1987, p. 7.

- ↑ RA Stasevich, GI Filinov: Information manual for parachutists (original: СПРАВОЧНОЕ ПОСОБИЕ ПАРАШЮТИСТУ ), military publisher of the Ministry of Defense of the USSR, Moscow 1959, p. 53 ff.