Clock key

A clock key (also clock key , French: Clef de Montre ) is a grip element for tensioning the drive spring or for winding up the weight of the clock .

In addition to the actual movement , a clock mechanism can also contain other assemblies, for example alarm clockwork , melody mechanism or striking mechanisms . These usually each have their own energy storage device, such as spiral springs or drive weights.

The tensioning of the drive spring and the winding up of the weight are colloquially referred to as pulling up .

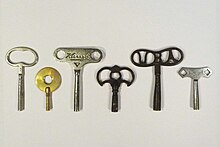

Designs

Socket wrench

Standard key with square

Plug -in clock keys are common for winding up spring-driven clockworks (wall clocks, table clocks). The square has established itself worldwide as a form-fitting connection between winding shaft and socket wrench . This is the square shaped end of a shaft or the spring core . The associated key is provided with an internal square that is only slightly larger than the square of the shaft.

Pendulum key

Some watches, such as B. French pendulum clocks , have a fine adjustment device with which the speed of the clockwork can be changed without touching the pendulum . There is also a small opening with a square in the dial above the 12 . The effective length of the pendulum is changed by turning this square.

There are double keys especially for such watches. At one end there is the inner square for pulling up the drive spring, at the other end there is a small inner square for fine adjustment.

Pocket watch key

Before the development of the crown winding system , pocket watches had two shafts with a square. One was used to wind the mainspring, the other to set the pointer. (see indication (clock) )

In order to protect the pocket watch key required for this from loss, the key was often attached directly to the watch chain.

Crank wrench

For winding the weight piece of regulators usually come crank key used.

The weights of old tower clocks are originally wound with cranks . Tower clocks that are still in operation are now often equipped with an electric elevator device.

Control knobs

From a technical point of view, adjusting knobs are also variants of clock keys , but are rarely referred to as such due to their shape and small size. Control knobs are mainly used on alarm clocks and small table clocks to set the alarm and time. Such knobs do not always have a square socket. To simplify production, many adjusting knobs have a round hole and are slotted at the end on the clockwork side. This end sits clamped on the square shaped end of a shaft. The slot enables a form fit between the adjusting knob and the corners of the shaft square.

Special key

Pluggable keys for technical clockworks, such as paper tape recorders or time clocks, can have a wide variety of shapes. There are star-shaped universal keys especially for watchmakers. These have several pens with inner square edges in five different sizes. Universal keys with even and odd sizes are common (see table Keys for large clocks )

Wrench

To make clock keys captive, they and the winding shaft are also provided with a thread. Such spanner or wrench are predominantly used on alarm clocks, travel clocks and table used.

If the winding is clockwise ( CW ), normal right-hand thread can be used. This is the case with most clocks that are wound from the dial side. Movements that are wound from the back or that have a longer running time (e.g. 1 month) are usually wound counter-clockwise ( CCW ). Then the clock key must be provided with a left-hand thread .

The various clockwork assemblies can also have different winding directions.

Using a wrench also prevents damage to the movement if the key is turned in the wrong direction.

It is not standardized whether the key has an external or internal thread.

material

Due to the forces to be transmitted and for the purpose of a long service life, watch keys consist almost exclusively of metals such as cast iron , zinc and brass . It was not until the middle of the 20th century that clock keys were made entirely or partially from plastic .

construction

Watch keys are cast in one piece from iron or zinc or assembled from individual parts by means of rivets , welding or brazing . When using plastic, injection molding is used.

Sizes

At the beginning of the watch production, each master craftsman worked according to his own ideas and experiences. There were no standards . Only with the transition to industrial watchmaking around 1900 did it become necessary to introduce uniform standards for toothing types , threads and also watch keys.

Although watch key manufacturers and dealers agree on this gradation, there is virtually no reliable source for a size gradation. The following tables have therefore been created using existing watch keys and dealer offers.

Key for large clocks

In Germany, keys for large clocks are graduated in steps of 0.25 mm (side length of the square). The clock keys are rarely marked with the size in millimeters. They usually have a size number or no marking at all. The following table shows the usual sizes for large clock keys in Germany.

size Square in mm 000 1.75 00 2.00 0 2.25 1 2.50 2 2.75 3 3.00 4th 3.25 5 3.50 6th 3.75 7th 4.00 8th 4.25 9 4.50 10 4.75 11 5.00 12 5.25 13 5.50 14th 5.75 15th 6.00

Keys for pocket watches

In Germany, a different gradation is used for pocket watch keys.

size Square in mm 00 2.00 0 1.90 1 1.80 2 1.75 3 1.65 4th 1.60 5 1.50 6th 1.40 7th 1.30 8th 1.20 9 1.15 10 1.05 11 1.00 12 0.95

Web links

- Uhrwerkstattforum: Technical clockworks - performance recorder Technical clockwork as a drive for the paper strip in a recording device (performance recorder)

- Big Ben: Winding the mechanism that powers the Great Clock Video on YouTube: Big Ben - Elevator of the great clock

- Pocket watch Watch Wiki: Pocket watch

Individual evidence

- ↑ Rudi Koch (Ed.): "BI-Lexicon Clocks and Time Measurement", VEB Bibliografisches Institut Leipzig, 1989, 2nd reviewed edition, p. 227

- ↑ ibid, pp. 15-16

- ^ Peter Held: "Uhrenbau Ein Werkbuch", historical watch books, publisher: Florian Stern, Berlin, 2012, pp. 149–150

- ↑ Rudi Koch (Ed.): "BI-Lexicon Clocks and Time Measurement", VEB Bibliografisches Institut Leipzig, 1989, 2nd reviewed edition, p. 227