Displacement sensor

A displacement sensor is used to measure the distance between an object and a reference point or changes in length . The change in the path is converted into a standard signal or transmitted to the control unit via a fieldbus . Other terms for this are displacement measuring system , displacement transducer , distance sensor , position sensor or distance sensor . This article provides an overview of the functional principles from the field of automation technology ; there are other methods outside of this → see distance measurement . A detailed description can be found in the linked articles.

In contrast to this, proximity switches generate a switching signal when approaching an object.

Operating principles

Change in resistance

- The potentiometer transmitter has a wiper on a resistor to which a constant voltage is applied. It directly supplies an output voltage that is linearly dependent on the path. The disadvantage is the wear caused by the friction of the grinder.

- The strain gauge changes its electrical resistance by changing its length and cross-section.

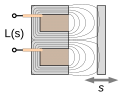

Variable inductance

With an inductive sensor , the inductance of a coil changes. Either the metallic object is measured without contact or a metallic core is moved in the coil with a probe head (plunger armature).

- The differential transformer (LVDT) has a moving core that influences the coupling factor to two secondary coils.

- In the case of the transverse anchor sensor , the air gap in a magnetic circuit is changed.

- With a short-circuit ring encoder, the effective air gap of a magnetic circuit is changed.

- The magneto-inductive distance sensor (MDS) measures the distance of a magnetic field even behind a non-magnetic partition.

- The eddy current sensor can also measure non-magnetic, but electrically conductive materials without contact.

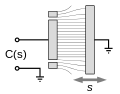

Variable capacity

The capacitive sensor consists of two metallic parts isolated from one another. Together with the device under test, it forms a capacitor with variable capacitance . The measuring effect is based on a geometric change in the distance between the two capacitor surfaces or a lateral displacement of these, which leads to a change in the effective capacitor surface.

Variable luminous flux

- After the silhouette method , a perpendicularly arranged for movement is light curtain shaded and therefrom determines the distance (optical microns).

- The fiber optic displacement sensor evaluates the brightness of a light barrier .

- The video extensometer uses a camera arranged at right angles to the movement to measure non-contact travel and elongation during tensile tests .

Count impulses

The incremental encoder has a periodic measuring standard (lines on glass or metal, magnetization on a magnetic tape, teeth on a rack). The sensor head is guided past it and emits signals that are counted up and down in the evaluation electronics. It only measures the difference to the position after switching on. Absolute encoders have several tracks and immediately show the absolute position.

The resolution can be increased by measuring the intensity of the signals within a graduation period.

- The glass scale uses this principle.

- The laser interferometer counts the interference from laser light.

Runtime measurement

The distance is calculated by measuring the time it takes a signal to traverse the measuring section.

- Laser range finders , the PMD sensor , LIDAR and radar sensors measure the transit time of electromagnetic waves.

- Ultrasonic sensors and the sonar measure the transit time of sound waves.

- The magnetostrictive displacement transducer determines the distance between a ring-shaped magnet by measuring the transit time of a torsion wave in a pipe.

Triangulation

The distance can be calculated by precisely measuring the angle within triangles.

- The laser triangulation sensor uses this principle.

Further procedures

- A spatially resolving photodiode converts the position of a point of light into changes in current.

- In fluid technology , the nozzle-baffle system can be used to convert a small path (0.017–0.02 mm) into a pressure signal.

With the conversion into a rotary movement, many angular position encoders can also be used, for example:

- Cable length encoder

- Distance pulse generator for rail vehicles

Smallest distances e.g. B. in the roughness measurement are optically measured by:

- Confocal technology : shifting the focal plane, measurement using a separate displacement sensor.

- Chromatic-confocal distance measurement : Distance is derived from the reflected wavelength.

- Conoscopic holography : Reconstruction of the distance from the angle information of the reflected light.

calibration

The assignment of the path change to an analog or digital signal and, if necessary, the definition of a zero point is carried out by calibration . For example, a change in travel of 1 mm corresponds to a voltage of 1 V.

In measurement technology , calibration is carried out by calibration laboratories . These are often certified by the German accreditation body .

Applications

Distance measurement is used, for example, when operating CNC controls or positioning systems. A strain sensor is used in materials testing or monitoring machines.

Displacement sensors can be used in automation technology e.g. B. can be used for quality assurance and for monitoring a running process . In this way, changes in height, outside diameter, thickness and length of the object can be controlled during the production process. If the corresponding value deviates from the target value, you can intervene in production.

References and literature

- ↑ Magneto-inductive distance sensors from Micro-Epsilon

- ↑ Jörg Böttcher: Online Compendium Measurement Technology and Sensor Technology: Capacitive and Inductive Distance Sensors. Accessed July 31, 2019 .

- ↑ Hans-Jürgen Gevatter (Ed.): Automation technology 2: Devices , Springer, 2000, p. 229, ( limited preview in the Google book search)

- T.Burkhardt, A.Feinäugle, S.Fericean, A.Forkl: Linear displacement and distance sensors: Contactless measuring systems for industrial use , Neuhausen 2004, ISBN 3937889078

- David S. Nyce: Linear Position Sensors: Theory and Application. , New Jersey, John Wiley & Sons Inc. (2003)