Piezoelectricity

Piezoelectricity is the ability of some materials (notably crystals and certain ceramics) to generate an electric potential[1] in response to applied mechanical stress. This may take the form of a separation of electric charge across the crystal lattice. If the material is not short-circuited, the applied charge induces a voltage across the material. The word is derived from the Greek piezein, which means to squeeze or press.

The piezoelectric effect is reversible in that materials exhibiting the direct piezoelectric effect (the production of electricity when stress is applied) also exhibit the converse piezoelectric effect (the production of stress and/or strain when an electric field is applied). For example, lead zirconate titanate crystals will exhibit a maximum shape change of about 0.1% of the original dimension.

The effect finds useful applications such as the production and detection of sound, generation of high voltages, electronic frequency generation, microbalances, and ultra fine focusing of optical assemblies. It is also the basis of a number of scientific instrumental techniques with atomic resolution, the scanning probe microscopies such as STM, AFM, MTA, SNOM etc.

Megasonic cleaning uses the piezoelectric effect to enable removal of submicron particles from substrates. A ceramic piezoelectric crystal is excited by high-frequency AC voltage, causing it to vibrate. This vibration generates an acoustic wave that is transmitted through a cleaning fluid, producing controlled cavitation. As the wave passes across the surface of an object, it causes particles to be removed from the material being cleaned. The technology was originally developed by the U.S. Navy as an element in anti-submarine warfare[2].

History

Discovery and early research

The first demonstration of the direct piezoelectric effect was in 1880 by the brothers Pierre Curie and Jacques Curie. They combined their knowledge of pyroelectricity with their understanding of the underlying crystal structures that gave rise to pyroelectricity to predict crystal behavior, and demonstrated the effect using crystals of tourmaline, quartz, topaz, cane sugar, and Rochelle salt (sodium potassium tartrate tetrahydrate). Quartz and Rochelle salt exhibited the most piezoelectricity.

The Curies, however, did not predict the converse piezoelectric effect. The converse effect was mathematically deduced from fundamental thermodynamic principles by Gabriel Lippmann in 1881. The Curies immediately confirmed the existence of the converse effect, and went on to obtain quantitative proof of the complete reversibility of electro-elasto-mechanical deformations in piezoelectric crystals.

For the next few decades, piezoelectricity remained something of a laboratory curiosity. More work was done to explore and define the crystal structures that exhibited piezoelectricity.

World War I and post-war

The first practical application for piezoelectric devices was sonar, first developed during World War I.

The use of piezoelectricity in sonar, and the success of that project, created intense development interest in piezoelectric devices. Over the next few decades, new piezoelectric materials and new applications for those materials were explored and developed.

Piezoelectric devices found homes in many fields. Ceramic phonograph cartridges simplified player design, were cheap and accurate, and made record players cheaper to maintain and easier to build.

World War II and post-war

During World War II, independent research groups in the United States, Russia, and Japan discovered a new class of man-made materials, called ferroelectrics, which exhibited piezoelectric constants many times higher than natural materials. This led to intense research to develop barium titanate and later lead zirconate titanate materials with specific properties for particular applications.

Development of piezoelectric devices and materials in the United States was kept within the companies doing the development, mostly due to the wartime beginnings of the field, and in the interests of securing profitable patents. New materials were the first to be developed — quartz crystals were the first commercially exploited piezoelectric material, but scientists searched for higher-performance materials.

Japanese efforts in materials research created piezoceramic materials competitive to the U.S. materials, but free of expensive patent restrictions. Major Japanese piezoelectric developments include new designs of piezoceramic filters, used in radios and televisions, piezo buzzers and audio transducers that could be connected directly into electronic circuits, and the piezoelectric igniter which generates sparks for small engine ignition systems (and gas-grill lighters) by compressing a ceramic disc. Ultrasonic transducers that could transmit sound waves through air had existed for quite some time, but first saw major commercial use in early television remote controls.

Materials

Many materials, both natural and man-made, exhibit the piezoelectric effect:

Naturally-occurring crystals

- berlinite (AlPO4), a rare phosphate mineral that is structurally identical to quartz

- cane sugar

- quartz

- Rochelle salt

- topaz

- tourmaline-group minerals

Other natural materials

- Bone: Dry bone exhibits some piezoelectric properties due to the apatite crystals, and the piezoelectric effect is generally thought to act as a biological force sensor.[3][4] This effect was exploited by research conducted at the University of Pennsylvania in the late 1970s and early 80s which established that sustained application of electrical potential could stimulate both resorption and growth (depending on the polarity) of bone in-vivo. [5]

Man-made crystals

- gallium orthophosphate (GaPO4), a quartz analogic crystal

- Langasite (La3Ga5SiO14), a quartz analogic crystal

Man-made ceramics

The family of ceramics with perovskite or tungsten-bronze structures exhibits piezoelectricity:

- barium titanate (BaTiO3)—Barium titanate was the first piezoelectric ceramic discovered.

- lead titanate (PbTiO3)

- lead zirconate titanate (

[Template:ZirconiumTemplate:Titanium]Template:Oxygen 0<x<1)—more commonly known as PZT, lead zirconate titanate is the most common piezoelectric ceramic in use today. The article's lead section may need to be rewritten.

The article's lead section may need to be rewritten. - potassium niobate (KNbO3)

- lithium niobate (LiNbO3)

- lithium tantalate (LiTaO3)

- sodium tungstate (NaxWO3)

- Ba2NaNb5O5

- Pb2KNb5O15

Polymers

- Polyvinylidene fluoride (PVDF): PVDF exhibits piezoelectricity several times greater than quartz. Unlike ceramics, where the crystal structure of the material creates the piezoelectric effect, in polymers the intertwined long-chain molecules attract and repel each other when an electric field is applied.

Lead-free piezoceramics

More recently, there is growing concern regarding the toxicity in lead-containing devices driven by the result of restriction of hazardous substances directive regulations. Hence, there is an enormous insurgence in the compositional development of lead-free piezoelectric materials.

- Sodium potassium niobate (KNN). In 2004, Saito el al.[6] have found for the composition close to MPB, the material’s properties are close to PZT ceramics, and its Curie temperature is also high. For an grain-orientated ceramics can be match to those optimum modified PZT compositions.

- Bismuth ferrite (BiFeO3) is also a promising candidate for replacement lead-based ceramics.

Applications

Piezoelectric crystals are now used in numerous ways:

High voltage and power sources

Direct piezoelectricity of some substances like quartz, as mentioned above, can generate potential differences of thousands of volts.

- The best-known application is the electric cigarette lighter: pressing the button causes a spring-loaded hammer to hit a piezoelectric crystal, producing a sufficiently high voltage that electric current flows across a small spark gap, thus heating and igniting the gas. The portable sparkers used to light gas grills or stoves work the same way, and many types of gas burners now have built-in piezo-based ignition systems.

- A similar idea is being researched by DARPA in the United States in a project called Energy Harvesting, which includes an attempt to power battlefield equipment by piezoelectric generators embedded in soldiers' boots. However, these energy harvesting sources by association have an impact on the body. DARPA's effort to harness 1-2 Watts from continuous shoe impact while walking were abandoned due to the impracticality and the discomfort from the additional energy expended by a person wearing the shoes. Other energy harvesting ideas include harvesting the energy from human movements in train stations or other public places[7][8].

- A piezoelectric transformer is a type of AC voltage multiplier. Unlike a conventional transformer, which uses magnetic coupling between input and output, the piezoelectric transformer uses acoustic coupling. An input voltage is applied across a short length of a bar of piezoceramic material such as PZT, creating an alternating stress in the bar by the inverse piezoelectric effect and causing the whole bar to vibrate. The vibration frequency is chosen to be the resonant frequency of the block, typically in the 100 kilohertz to 1 megahertz range. A higher output voltage is then generated across another section of the bar by the piezoelectric effect. Step-up ratios of more than 1000:1 have been demonstrated. An extra feature of this transformer is that, by operating it above its resonant frequency, it can be made to appear as an inductive load, which is useful in circuits that require a controlled soft start.[1] These devices can be used in DC-AC inverters to drive cold cathode fluorescent lamps. Piezo transformers are some of the most compact high voltage sources.

Piezoelectric sensor

The principle of operation of a piezoelectric sensor is that a physical dimension, transformed into a force, acts on two opposing faces of the sensing element. Depending on the design of a sensor, different "modes" to load the piezoelectric element can be used: longitudinal, transversal and shear.

Detection of pressure variations in the form of sound is the most common sensor application, e.g. piezoelectric microphones (sound waves bend the piezoelectric material, creating a changing voltage) and piezoelectric pickups for electrically amplified guitars. A piezo sensor attached to the body of an instrument is known as a contact microphone.

Piezoelectric sensors especially are used with high frequency sound in ultrasonic transducers for medical imaging and also industrial nondestructive testing (NDT).

For many sensing techniques, the sensor can act as both a sensor and an actuator - often the term transducer is preferred when the device acts in this dual capacity, but most piezo devices have this property of reversibility whether it is used or not. Ultrasonic transducers, for example, can inject ultrasound waves into the body, receive the returned wave, and convert it to an electrical signal (a voltage). Most medical ultrasound transducers are piezoelectric.

In addition to those mentioned above, various sensor applications include:

- Piezoelectric elements are also used in the detection and generation of sonar waves.

- Power monitoring in high power applications (e.g. medical treatment, sonochemistry and industrial processing).

- Piezoelectric microbalances are used as very sensitive chemical and biological sensors.

- Piezos are sometimes used in strain gauges.

- Piezoelectric transducers are used in electronic drum pads to detect the impact of the drummer's sticks.

- Automotive engine management systems use a piezoelectric transducer to detect detonation, by sampling the vibrations of the engine block.

- Ultrasonic piezo sensors are used in the detection of acoustic emissions in acoustic emission testing.

Actuators

As very high voltages correspond to only tiny changes in the width of the crystal, this width can be changed with better-than-micrometer precision, making piezo crystals the most important tool for positioning objects with extreme accuracy — thus their use in actuators.

- Loudspeakers: Voltages are converted to mechanical movement of a piezoelectric polymer film.

- Piezoelectric motors: piezoelectric elements apply a directional force to an axle, causing it to rotate. Due to the extremely small distances involved, the piezo motor is viewed as a high-precision replacement for the stepper motor.

- Piezoelectric elements can be used in laser mirror alignment, where their ability to move a large mass (the mirror mount) over microscopic distances is exploited to electronically align some laser mirrors. By precisely controlling the distance between mirrors, the laser electronics can accurately maintain optical conditions inside the laser cavity to optimize the beam output.

- A related application is the acousto-optic modulator, a device that scatters light off of sound waves in a crystal, generated by piezoelectric elements. This is useful for fine-tuning a laser's frequency.

- Atomic force microscopes and scanning tunneling microscopes employ converse piezoelectricity to keep the sensing needle close to the probe.

- Inkjet printers: On some inkjet printers, particularly those made by Epson, piezoelectric crystals are used to control the flow of ink from the inkjet head to the paper.

- Diesel engines: high-performance common rail diesel engines use piezoelectric fuel injectors, first developed by Robert Bosch LLC, instead of the more common solenoid valve devices.

Frequency standard

The piezoelectrical properties of quartz are useful as standard of frequency.

- Quartz clocks employ a tuning fork made from quartz that uses a combination of both direct and converse piezoelectricity to generate a regularly timed series of electrical pulses that is used to mark time. The quartz crystal (like any elastic material) has a precisely defined natural frequency (caused by its shape and size) at which it prefers to oscillate, and this is used to stabilize the frequency of a periodic voltage applied to the crystal.

- The same principle is critical in all radio transmitters and receivers, and in computers where it creates a clock pulse. Both of these usually use a frequency multiplier to reach the megahertz and gigahertz ranges.

Piezoelectric motors

Types of piezoelectric motor include the well-known travelling-wave motor used for auto-focus in reflex cameras, inchworm motors for linear motion, and rectangular four-quadrant motors with high power density (2.5 watt/cm3) and speed ranging from 10 nm/s to 800 mm/s. All these motors work on the same principle. Driven by dual orthogonal vibration modes with a phase shift of 90°, the contact point between two surfaces vibrates in an elliptical path, producing a frictional force between the surfaces. Usually, one surface is fixed causing the other to move. In most piezoelectric motors the piezoelectric crystal is excited by a sine wave signal at the resonant frequency of the motor. Using the resonance effect, a much lower voltage can be used to produce a high vibration amplitude.

Reduction of vibrations

The TU Darmstadt in Germany researches ways to reduce and stop vibrations by attaching piezo elements. When the material is bent by a vibration in one direction, the system responds to the bend and sends electric power to the piezo element to bend in the other direction.

Such an experiment was shown at the Material Vision Fair in Frankfurt in November 2005. Several panels were hit with a rubber mallet, and the panel with the piezo element immediately stopped swinging.

The research team sees future applications in cars and houses to reduce noise.

Piezoelectric ceramic fiber technology is being used as an electronic dampening system on some Head tennis rackets.[9][10]

Crystal classes

Of the thirty-two crystal classes, twenty-one are non-centrosymmetric (not having a centre of symmetry), and of these, twenty exhibit direct piezoelectricity (the 21st is the cubic class 432). Ten of these are polar (i.e. spontaneously polarize), having a dipole in their unit cell, and exhibit pyroelectricity. If this dipole can be reversed by the application of an electric field, the material is said to be ferroelectric.

- Piezoelectric Crystal Classes: 1, 2, m, 222, mm2, 4, -4, 422, 4mm, -42m, 3, 32, 3m, 6, -6, 622, 6mm, -62m, 23, -43m

- Pyroelectric: 1, 2, m, mm2, 4, 4mm, 3, 3m, 6, 6mm

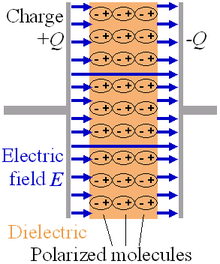

Mechanism

In a piezoelectric crystal, the positive and negative electrical charges are separated, but symmetrically distributed, so that the crystal overall is electrically neutral. Each of these sites forms an electric dipole and dipoles near each other tend to be aligned in regions called Weiss domains. The domains are usually randomly oriented, but can be aligned during poling (not the same as magnetic poling), a process by which a strong electric field is applied across the material, usually at elevated temperatures.

When a mechanical stress is applied, this symmetry is disturbed, and the charge asymmetry generates a voltage across the material. For example, a 1 cm cube of quartz with 2 kN (500 lbf) of correctly applied force upon it, can produce a voltage of 12,500 V. [11]

Piezoelectric materials also show the opposite effect, called converse piezoelectric effect, where the application of an electrical field creates mechanical deformation in the crystal.

Mathematical description

Piezoelectricity is the combined effect of the electrical behavior of the material:

Where D is the electric charge density displacement (electric displacement), is permittivity and E is electric field strength, and Hooke's Law:

Where S is strain, s is compliance and T is stress.

These may be combined into so-called coupled equations, of which the strain-charge form is:

where is the matrix for the direct piezoelectric effect and is the matrix for the converse piezoelectric effect. The superscript E indicates a zero, or constant, electric field; the superscript T indicates a zero, or constant, stress field; and the superscript t stands for transposition of a matrix.

The strain-charge for a material of the 4mm (C4v) crystal class (such as a poled piezoelectric ceramic such as tetragonal PZT or BaTiO3) as well as the 6mm cystal class may also be written as (ANSI IEEE 176):

where the first equation represents the relationship for the converse piezoelectric effect and the latter for the direct piezoelectric effect.[12]

Although the above equations are the most used form in literature, some comments about the notation are necessary. Generally D and E are vectors, that is, Cartesian tensor of rank-1; and permittivity is Cartesian tensor of rank-2. Strain and stress are, in principle, also rank-2 tensors. But conventionally, because strain and stress are all symmetric tensors, the substript of strain and stress can be re-labeled in the following fashion: ; ; ; ; ; . (Different convention may be used by different authors in literature. Say, some use ; ; instead.) That is why S and T appear to have the "vector form" of 6 components. Consequently, s appears to be a 6 by 6 matrix instead of rank-4 tensor. Such a re-labeled notation is often called Voigt notation.

In total, there are piezoelectric 4 coefficients, dij, eij, gij, and hij defined as follows [13]:

where the first set of 4 terms correspond to the direct piezoelectric effect and the second set of 4 terms correspond to the converse piezoelectric effect.

See also

- Electronic components

- Ferroelectric effect

- Electret

- Magnetostriction

- Electrostriction

- Charge amplifier

- Piezoresistive effect

References

International Standards

- ANSI-IEEE 176 (1987) Standard on Piezoelectricity

- IEEE 177 (1976) Standard Definitions & Methods of Measurement for Piezoelectric Vibrators

- IEC 444 (1973) Basic method for the measurement of resonance freq & equiv series resistance of quartz crystal units by zero-phase technique in a pi-network

- IEC 302 (1969) Standard Definitions & Methods of Measurement for Piezoelectric Vibrators Operating over the Freq Range up to 30MHz

Other references

- ^ Principles of Instrumental Analysis. 6th Edition, 2007. Skoog, Holler, and Crouch. Chapter 1, Sec. 1C-4, Pg. 9.

- ^ ProSys, Inc. - What is Megasonic Cleaning?

- ^ Electrical Properties of Bone: A Review, Roderic Lakes

- ^ Robert O. Becker and Andrew A. Marino, Electromagnetism & Life, State University of New York Press, Albany, ISBN 0-87395-560-9 Chapter 4: Electrical Properties of Biological Tissue (Piezoelectricity)

- ^ Pollack, S.R., Korostoff, E., Starkebaum, W. y Lannicone, W. (1979) Micro-electrical studies of stress-generated potentials in bone. in Electrical Properties of Bone and Cartilage, (Edit. Brighton, C.T., Black, J. & Pollack, S.R.), Grune & Stratton, Inc., New York.

- ^ Saito, Y. et al. Nature 432, 81-87 (2004)

- ^ Japan: Producing Electricity from Train Station Ticket Gates

- ^ 'Crowd Farm' — MIT project on harvesting energy of human movement in urban settings, like commuters in a train station or fans at a concert.

- ^ "Isn’t it amazing how one smart idea, one chip and an intelligent material has changed the world of tennis?" Accessed February 27, 2008

- ^ "Advanced Cerametrics - Ceramic Fibers and Components, Energy Harvesting Materials"Accessed February 27, 2008

- ^ Sensor Sense: Piezoelectric Force Sensors

- ^ Damjanovic, Dragan, 1998, Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics, Rep. Prog. Phys. 61, 1267–1324.

- ^ Kochervinskii, V. V., 2003, Piezoelectricity in Crystallizing Ferroelectric Polymers, Crystallography Reports, 48(4), 649–675.

- 'The piezoelectrical effect'

- 'Piezo Tutorial Force Equations'

- Gautschi, Gustav H., 2002, Piezoelectric Sensorics, Springer, ISBN 3540422595, [2]

- 'History of Piezoelectricity'

- "Piezoelectric Constitutive Equation" from Engineering Fundamentals

![{\displaystyle \{S\}=\left[s^{E}\right]\{T\}+[d^{t}]\{E\}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/88c730a6c15c93312ca9bf57bd4a7876f18a22ac)

![{\displaystyle \{D\}=[d]\{T\}+\left[\epsilon ^{T}\right]\{E\}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/6796c67cea6776871fb045a554842d7e615261b2)

![{\displaystyle [d]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/ef4f4d84e860f2ffd5b55eec14cfbf735dd01689)

![{\displaystyle [d^{t}]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/ce92f74e9b6337507d823effde217ab06692f45e)