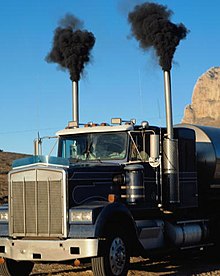

Diesel soot

Diesel soot particles are always produced when diesel fuel is burned in diesel engines . Together with other particles, they form fine dust . Exhaust gases that visibly contain diesel soot are also known as black smoke .

Formation of diesel soot

Hydrocarbon flames tend to produce soot in fuel-rich conditions . However, fuel-rich conditions are unavoidable in diffusion flames . As a result, direct-injection petrol engines are also affected by “diesel” soot formation, as the amount of fuel injected increases, especially at higher loads and higher engine speeds, while the time available for mixture preparation is reduced. Large droplets of fuel cannot evaporate sufficiently, are cracked by the combustion temperature and are therefore a source of unburned carbon (soot). The highest amount of soot is recorded at full load , while speeds of just a few percent under full load lead to a significant reduction in soot emissions.

Soot formation mechanisms

Soot consists of a large number of particles of different shapes and sizes. Measurable parameters include the particle density, the soot volume fraction and the mean particle diameter. The formation and growth of soot are divided into particle formation, coagulation and surface processes as well as an agglomeration of the primary particles.

Particle formation

Both by oxidation processes and by thermal pyrolysis , the fuel molecules are broken down into acetylene under low-oxygen conditions . In this case, hydrogen cleaved from the molecule, so that there are initially small, less saturated hydrocarbons. These reactions are endothermic and therefore strongly dependent on temperature. Acetylene reacts with CH or CH 2 to form C 3 H 3 , which can then form a so-called aromatic ring through recombination and rearrangement. The subsequent addition of acetylene results in high molecular weight polycyclic hydrocarbons (PAHs) through further H abstraction and C 2 H 2 addition. Such condensation processes are characterized by the fact that the more construction steps are required, the more they depend on the air ratio. During the agglomeration (Latin coagulation) of the planar PAHs , the first three-dimensional structures emerge from the gas phase.

The structure of the hydrocarbon molecules present in diesel oil is also important for particle formation. Carbon-rich molecules with numerous double bonds, e.g. B. aromatics, form soot and PAH more easily than alkanes (paraffins and naftens). In Sweden, soot and PAH formation in diesel engines was determined depending on the aromatic content in various diesel fuels, e.g. B. examined by AVL MTC AB in the Jordbro south of Stockholm. Because of these results, the Swedish government has reduced taxes on diesel fuels with lower aromatic content. Swedish diesel fuel never has more than 5 percent by volume aromatics and never more than 0.02 percent by weight polyaromatic hydrocarbons (PAH).

Surface growth

Further dehydrogenation and addition of acetylene increases the particle size and mass while the number of particles remains constant. Here, too, acetylene plays an important role, since growth again takes place via H abstraction / C 2 H 2 addition mechanisms between the nuclei and the gas phase. The ratio of hydrogen (H) to carbon (C) continues to decrease, as a result of which, with increasing size, the particles lose their affinity for acetylene through a decrease in their radical and ionic properties. Surface growth is possible relative to acetylene formation and polymerization even at low temperatures and low HC concentrations. For this reason, enough time is available for this reaction phase in technical combustion processes. About 95 percent of the total amount of soot is formed via the surface growth.

Coagulation

Particle collisions lead to an increase in the size of the soot particles, known as coagulation. The number of particles decreases at a constant soot mass. As surface growth continues, particle coagulation quickly leads to the formation of larger particles. The coagulation has a decisive influence on the size distribution of the soot, whereby the size distribution of particles in the exhaust gas can be described by a logarithmic normal distribution function.

Agglomeration

This describes the formation of chain-like structures that arise when there are no longer enough hydrocarbons in the gas phase or when the reactivity of the particles decreases. Neither of the two conditions is met during the combustion and expansion phase, which means that agglomerates only form after a certain period of time outside the combustion chamber. These aggregated particles can consist of several thousand individual particles and have a diameter in the size range from 50 to 100 nanometers (nm).

Soot oxidation

Most of the soot is oxidized inside the cylinder. The high specific surface area of the particles enables effective oxidation , with molecular oxygen and radicals such as HO • being possible oxidizers . Below about 1800 K, the influence of oxygen on the particle lifetime is negligible. The oxidation times increase exponentially as the temperature falls.

Particle reduction in diesel engines

In the past few years, the soot emissions from diesel engines could be reduced considerably through improved combustion technology. Both the emitted mass and the particle concentration decreased. In the case of supercharged engines, when accelerating due to incomplete combustion (which can no longer be compensated by the control system), there may be a short-term significant increase in the soot mass, the so-called soot surge. In order to further reduce soot emissions, particulate filters have increasingly been offered by automobile manufacturers in recent years . The efficiency of the particle filter is also very good for ultra-fine dust . The only gradual decrease in particle emissions is due to the long service life of older vehicles.

Diesel that is very low in aromatic compounds and low in sulfur is sold at many petrol stations - mostly under separate brand names.

Filter technology for diesel vehicles

The particle filters currently used for equipment ex works are so-called wall-flow filters, in which the exhaust gas flow is directed through a porous wall. The particles are deposited on the porous wall as they pass through, which results in a surface filtrate. On the surface of the wall, a filter cake is formed from the separated particles. The filter efficiency is up to over 99 percent.

The exhaust gas has to flow both through the growing soot cake and through the filter wall. The exhaust back pressure increases due to the growing soot layer build-up, which results in increased fuel consumption. When a loading limit value is exceeded and to protect the particle filter from excessively high temperatures during regeneration, measures are therefore initiated to regenerate the particle filter.

The particle filtrate consists predominantly of combustible soot and hydrocarbons adhering to it. A small part consists of non-flammable components. In the simplest form of filter regeneration, the particle filter temperature is raised above the ignition temperature of the soot (approx. 600 ° C). During this operating phase, the engine does not work with optimum efficiency, which means that additional fuel consumption is required. After regeneration, the soot layer is burned up down to the non-combustible components (the filter ash ). The main combustion product is carbon dioxide .

Identified health hazards

Diesel soot was previously only considered likely to be carcinogenic, i.e. H. carcinogenic. On June 12, 2012, the World Health Organization finally classified diesel soot as definitely carcinogenic after a long-term scientific study and thus placed it on a par with asbestos and arsenic . This applies to relatively coarse particles, such as those caused by open fire or heating systems, as well as to smaller particles from engines. However, the smaller the particles, the more dangerous they are: some coarse particles can even be filtered by the nose, while the particles of modern diesel engines can even penetrate the skin into the bloodstream and reach the brain via the bloodstream.

The particles that modern diesel engines emit are classified as fine dust and are very fine and smaller than ten micrometers or even smaller than a tenth of a micrometer in diameter and can therefore penetrate deep into the lungs . The ultrafine particles even go into the bloodstream and are distributed throughout the body. The pollution of the air by these ultrafine particles, which arise when diesel fuel is burned in modern diesel engines due to the high injection pressures and the resulting extremely fine atomization of the diesel, can currently hardly be recorded using measurement technology, as the systems installed for air quality measurement are not designed for this . In animal experiments with very high concentrations of fine dust, a significant increase in cancer disease could be demonstrated , depending on the animal species examined . Further studies have shown that carcinogenic changes occur in various types of particulate matter. In people who are exposed to a very high dust concentration for a long time, diseases, especially of the lungs, have been proven and recognized as occupational diseases (for example, dusty lungs in underground workers). It is not yet known whether there is a threshold above which such diseases occur. Since fine dust occurs independently of human activities, meaningful long-term epidemiological studies are very difficult to carry out, as an unpolluted comparison group cannot be determined.

Political measures

Since January 1, 2005, new EU limit values for fine dust according to EC Directive 1999/30 / EC have been in effect. In the first year, the limit values were not observed at 41 measuring stations on more than the permissible 35 days. The most frequent exceedances occurred in large cities on busy streets, Stuttgart and Munich were the leaders with 107 days.

Epidemiological calculations of diesel soot mortality in Germany

The epidemiologist Heinz-Erich Wichmann calculated 14,400 additional deaths per year from diesel soot alone. The statistical interval ranges from around 10,000 to 19,000. The parameters used are based on studies of the long-term effects of particulate matter and the corresponding mortality. The Umwelt- und Prognose-Institut (UPI) in Heidelberg previously calculated on a different basis of data only about 8500 deaths per year as a result of lung cancer from diesel soot.

Both sources do not contradict each other, since the calculations by H. Erich Wichmann (Study 2352 by the Federal Environment Agency) include not only mortality from lung cancer, but also from other diseases caused by diesel soot.

See also

swell

- Institute of Environmental Medicine in Umeå

- H. Erich Wichmann: Assessment of positive health effects through the use of particle filters in diesel vehicles in Germany. Umweltbundesamt Berlin 2003. Report 2352, especially page 32 on mortality (PDF; 610 kB).

- Federal Environment Agency Berlin Future Diesel. Emissions legislation for passenger cars, light commercial vehicles and trucks - update of the limit values for diesel vehicles (PDF; 1.8 MB) 2003. Report 2353, in particular page 25 on mortality.

Individual evidence

- ↑ H. Holtei: Newer measurement methods for determining diesel engine emissions. In: VDI Commission for keeping the air clean, VDI Society for Vehicle Technology: Reducing emissions from automobile exhaust gases - diesel engines. VDI-Verlag Düsseldorf 1985, ISBN 3-18-090559-X , pp. 319–334.

- ↑ Wissenschaft.de: Diesel soot - Seven surprising answers - Bild der Wissenschaft, from December 1, 1999 , accessed on February 17, 2017

- ↑ Brigitte Fritsch: Automobile manufacturer on the way to sustainability: Individual transport on the move into the 21st century . Diplomica Verlag, 2014, ISBN 978-3-8428-9883-7 , p. 71 ( limited preview in Google Book search).

- ↑ Rolf Isermann: Model-based control, regulation and diagnosis of internal combustion engines . Springer-Verlag, 2011, ISBN 978-3-642-55698-2 , p. 180 ( limited preview in Google Book Search).

- ↑ patent-de.com: Method for improving the response behavior of turbochargers - Document DE10061796A1 , accessed on February 17, 2017

- ↑ Hans-Josef Allelein, Elmar Bollin, Helmut Oehler, Udo Schelling, Harald Schwarz: Energy technology systems for energy conversion. Compact knowledge for studies and work . Springer-Verlag, 2012, ISBN 978-3-8348-2279-6 , pp. 203 ( limited preview in Google Book search).

- ↑ Ultrafine Particulate Matter and the Benefits of Reducing Particle Numbers in the United States - A Report to the Manufacturers of Emission Controls Association (MECA) , Prepared by Gladstein, Neandross & Associates, July 2013

- ↑ Gunter Zimmermeyer, Bernhard Lüers, Bastian Holderbaum: The way to a clean diesel engine. In: Hazardous substances - cleanliness. Air . 77, No. 6, 2017, ISSN 0949-8036 , pp. 215-223.

- ↑ IARC: DIESEL ENGINE EXHAUST CARCINOGENIC, June 12, 2012 (PDF; 190 kB).

- ↑ Fine dust (PM10): exceedances per year; complete data. (No longer available online.) Archived from the original on September 27, 2007 ; Retrieved October 20, 2011 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.