Compressed air tram in Bern

| Compressed air tram in Bern | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Bear place with compressed air tram

| |||||||||||||||||||||

|

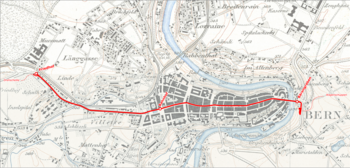

Range, 1890

| |||||||||||||||||||||

| Route length: | 2.927 km | ||||||||||||||||||||

| Gauge : | 1000 mm ( meter gauge ) | ||||||||||||||||||||

| Maximum slope : | 52 ‰ | ||||||||||||||||||||

| Minimum radius : | 30 m | ||||||||||||||||||||

| Bärengraben – Bahnhof – Friedhof | |||||||||||||||||||||

|

|||||||||||||||||||||

The Bern compressed air tram , also known as the Lufttram , was a tram operated by the Berner Tramway-Gesellschaft (BT) with compressed air railcars according to the Mékarski system in the Swiss federal city of Bern . It operated from 1890 to 1902 and was then replaced by an electric tram.

history

As early as 1882, the Bern Land Company applied for a tram concession in Bern. The concession expired, however, because the company could not produce a contract for the use of the streets and squares of the city. The Berner-Tramway-Gesellschaft received the concession for the construction of the Bärengraben - Bahnhof - Friedhof route on July 19, 1889, but only after it had undertaken to operate the tram with compressed air railcars. Other systems were excluded. The inclines were too big for a horse-drawn tram , a steam tram was undesirable because of the nuisance caused by smoke. If possible, the hydropower of the Aare should be used for the tram. A cable tram would have been too expensive; a conventional tram with electrical overhead lines was undesirable because of the disfigurement of the cityscape, and the technology for operation with accumulator railcars was not yet sufficiently developed.

The construction of the tram was given to Gaston Anselmier for a fixed amount of 410,000 SFr. to hand over. This amount also included the delivery of the vehicles to be fitted with the compressed air drive developed by the French engineer Louis Mékarski .

route

The 2.927 km long route led from Bärengraben through the old town of Bern to the train station, from there it followed Laupenstrasse and branched off into Murtenstrasse at Inselplatz. The end point was at the Bremgarten cemetery . The route was laid out in a single lane, but there were eight passing points . At the end of the route there were turntables with a diameter of three meters, because the pneumatic railcars could only run in one direction.

building

Wooden waiting halls were built near the cemetery, Inselspital and the bear pit . A depot and administration building with a workshop and official apartment for the depot manager was built near the Bärengraben. The depot had four tracks: two tracks were used to charge the railcars with compressed air, the third was only used as a siding and the fourth was used for repairs to the railcars. There was also a transfer table in the depot .

The compressors for the air supply to the railcars were installed in a building on the Aare 60 meters from the Matte power station . The four two-stage compressors were driven by the power station with a cable transmission and generated compressed air with a pressure of 32 atm . After compression, the air was passed through two air dryers, in which the water was separated by deflecting the air flow several times.

Two 670 meter long compressed air lines led from the compressor house to the tram depot, where the railcars could be filled. The second line was created because Mékarski did not trust the rubber seals used in the first line and therefore provided the second line with lead seals.

The depot at Grossen Muristalden 6 ⊙ has been preserved. From 1941, when the now electrified tram line to Bärengraben was shut down, it was converted into a car garage and later used as a depot for the Bern City Theater . The Altes Tramdepot restaurant has been located here since 1998 . The building, together with a bus shelter (Grosser Muristalden 1A ⊙ ), is one of the buildings in the inventory of the city of Bern that is worthy of protection and is intended to be a reminder of the aerial tram.

vehicles

| Railcar, compressed air tram, Bern | |

|---|---|

|

Car no. 7 of the Bern compressed air tram around 1890 near Bärengraben

|

|

| Numbering: | 1-10 |

| Number: | 10 |

| Manufacturer: | Mékarski Consortium: |

| Year of construction (s): | 1890 |

| Retirement: | 1901 |

| Axis formula : | B. |

| Gauge : | 1000 mm ( meter gauge ) |

| Length over buffers: | 6.8 m |

| Total wheelbase: | 1.6 m |

| Empty mass: | 8.3 t |

| Service mass: | 9.3 t |

| Top speed: | 15 km / h |

| Starting tractive effort: | approx. 30 kN |

| Driving wheel diameter: | 700 mm |

| Control type : | Walschaert |

| Number of cylinders: | 2 |

| Cylinder diameter: | 130 mm |

| Piston stroke: | 220 mm |

| Cylinder pressure: | 12–5 atm |

| Boiler overpressure: | 30 atm |

| Tank capacity: | 2120 liters |

| Drive: | two-cylinder piston machine operated with compressed air |

| Brake: | Direct acting air brake |

| Speedometer: | Hipp |

| Seats: | 16 |

| Standing room: | 25th |

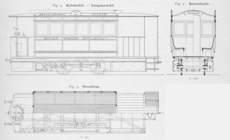

Ten compressed air railcars, which were called automobiles , were procured for the operation of the line . They were built by a consortium under the direction of Mékarski, the developer of the technology for the compressed air drive. It owned the Société des Moteurs à Air Comprimé von Mékarski with its headquarters in Paris, the machine works in Bern run by Ludwig and Schopfer and the machine works P. Blanchod & Cie. , a predecessor of the Ateliers de constructions mécaniques de Vevey , in Vevey . Originally, trailer operation was planned during peak times, but this was rejected by the supervisory authority.

The railcars could only run in one direction and were therefore turned on a turntable at the end of the route. The air supply was located under the floor of the car in ten cylindrical pressure vessels with a total volume of 1820 liters . After the first attempts, the volume of air carried turned out to be too small, so that two additional tanks with a capacity of 150 liters each were installed under the benches inside the car. The first axis was driven by a two-cylinder piston engine, the second axis was driven by coupling rods. The engine was completely encased and only accessible via the maintenance hatches on the side.

Hot water was used to heat the air so that no ice could form in the piston machine due to the evaporation cold that occurs when the compressed air is released. The water was in a vertical front of the cart leader standing 100-liter carried tank and was heated with steam during the maintenance stop at the depot for charging the air tanks. The air flowing to the cylinders of the piston steam engine flowed through the tank from bottom to top. At the top of the tank was the pressure control valve that the driver operated. The vehicle had two brake cylinders, which were also operated using the vehicle's compressed air supply.

The car body was a sheet metal construction with sliding doors and retractable windows. Inside there were two longitudinal benches for eight people each, the rear platform was designed for standing room for twelve. The cars were equipped with an air brake. Outside, kerosene lamps provided the track lighting and also served as signal light. For the interior lighting, kerosene lamps were also used, which were attached to the end walls. A hot water heater with radiators under the longitudinal benches should heat the interior in the cold season. The water was supposed to be heated with a coke -fired oven in the cab floor.

business

The first test drives were carried out on May 31, 1890. It turned out that the air supply was insufficient, so that the railcars could no longer enter the depot after driving from the bear pit to the cemetery and back. To remedy this deficiency, the air volume on the railcars was increased by additional tanks and the curve at the entrance was converted from a 25 m radius to a 30 m radius so that it was easier to drive.

Regular operations began on October 1, 1890. A drive from the bear pit to the cemetery took 20 minutes . During the day the railcars ran every ten minutes, from 8 p.m. only every twenty minutes. The operating time was from 6:30 a.m. to 10:50 p.m. In addition to the seven designated stops, the wagons also stopped at other places at the request of travelers. The cars ran with a driver and a conductor on the rear platform, who was known as a ticket agent . Seven railcars were needed to operate the tram: five were on the move, two were in the charging station in the depot. The actual charging process only took eight minutes, but the whole process of connecting and disconnecting the cables and turning off the vehicle took 20 minutes. The speed in the streets was set at 12 km / h in the old town and 15 km / h in the less busy outlying areas. At the request of the supervisory authority, speedometers from the Hipp system had to be installed.

The air tram was in operation for ten years. When the water level in the Aare was low, problems arose because the compressors could not draw enough air to operate the tram. In winter, the air lines from the compressor house to the depot sometimes froze, so that operations had to be stopped. Sometimes trams got stuck because the drivers were not careful with the air supply.

literature

- A. Bertschinger: The tramway system in the city of Bern: System Mekarski . In: Schweizerische Bauzeitung . tape 16 .

- Part 1 . No. 25 , December 20, 1890, pp. 154–157 , doi : 10.5169 / seals-16470 .

- Part 2 . No. 26 , December 27, 1890, pp. 160–163 , doi : 10.5169 / seals-16471 .

Web links

Individual evidence

- ↑ Transport companies. Accessed January 1, 2020 .

- ↑ a b c d e f Swiss construction newspaper

- ↑ Swiss construction newspaper. P. 160. Sp. Right

- ↑ Grosser Muristalden 6. Old tram depot. In: Building inventory of the city of Bern. 2017, accessed January 9, 2020 .

- ↑ Grosser Muristalden 1A. Bus shelter. In: Building inventory of the city of Bern. 2017, accessed January 9, 2020 .

- ↑ Schweizerische Bauzeitung, p. 156, column links

- ↑ Claudia Hermann: With compressed air through the city . In: Schweizerisches Verkehrshaus (Ed.): Verkehrshaus Magazin . No. 17 , March 2015, p. 8-9 ( issuu.com ).

- ↑ a b Schweizerische Bauzeitung, p. 157, column left

- ↑ Swiss construction newspaper. P. 156. Sp. Right

- ↑ Schweizerische Bauzeitung, p. 157, column on the right

- ^ History. In: tram-bus-bern.ch. Retrieved January 12, 2020 .