Metallic effect pigment

Metallic effect pigments , outdated bronzes are platelet-shaped, metallic pigments . The optical effect of these effect pigments is based on the alignment of the platelets parallel to the surface of the surrounding system, on which a directed reflection occurs. They are listed in the Color Index under CI Pigment Metal.

Metallic effect pigments are used to achieve gloss effects in printing inks , plastics, cosmetics and paints (see metallic paint and metal flake paint ) . Aluminum (CI Pigment Metal 1, historically silver bronze ) and brass (CI Pigment Metal 2, gold bronze ) have the greatest economic importance . It is estimated that the world market for metal effects is 25,000 tons annually.

history

Metallic effect pigments are the oldest subgroup within the effect pigments next to pearlescent pigments . The basic idea developed in the fourth to third centuries BC from the gold beating trade in Egypt . The waste that arises when gold is knocked out into very thin foils was stirred into the forerunners of modern paint systems so that they were given a golden color. Brass has been used instead of expensive gold since the 18th century AD . Later, fine aluminum flakes were also made, which were used to create a silver hue.

The first process for the large-scale production of aluminum pigments was developed in the USA in 1910 ( tamping process ). Since it was a dry milling process, the risk of an explosion was very high, so that the process was quickly replaced by a wet milling process called the “Hall process” after the inventor and patent holder. Dry grinding is still common for brass pigments.

Classification

Leafing and non-leafing types

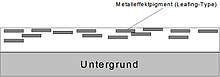

A basic distinction is made between leafing and non-leafing pigments . With the former, the platelets orient themselves on the surface after application in the coating film . This creates a strong metallic gloss impression, which, however, is not smudge-proof and scratch-proof. Areas of application are printing inks, reflective varnishes and aerosol varnishes , as the optical effect is decisive in these applications. Brass pigments are basically leafing types.

Non-leafing pigments are distributed evenly in the film matrix after application. As a result, they are protected against abrasion and attack by chemicals, which is why they appear grayer in color and less “metallic shine”. In addition, they can be combined with colored pigments to create colored metallic effects. This is only possible in low concentrations with leafing pigments, as these cover up the colored pigments evenly distributed in the paint due to the concentration on the paint surface. The main areas of application for non-leafing are automotive paints, paints for cell phones or electrical parts and general industrial paints .

Surface texture

The standard types are also known as cornflakes due to their shape . These are flakes that are very irregularly shaped and have an uneven surface. The cornflakes represent the original form of the metallic effect pigments. Rounded flakes with a smooth surface have been available since the early 1990s. These are also known as silver dollars because of their shape and appear brighter and brighter than the cornflake types and are therefore used in many modern paint finishes. Silver dollar types are made from a specially adjusted semolina with a spherical surface. This is not crushed during grinding, but only deformed.

High purity types

In the past, aluminum types with a very high aluminum content were often used for high-quality paintwork, such as for automobiles. These types offer significantly better corrosion protection compared to standard types. However, due to the two-layer technology that has now prevailed (overcoating with clear lacquer ), these types have lost their importance.

Manufacturing

The metal to be processed (aluminum or brass) is first melted and, after reaching the melting temperature, is atomized out of the melt. This creates irregularly shaped, spherical particles ( grit ). The metal powders are then shaped into flakes in ball mills and crushed. This occurs when aluminum pigments in white spirit and lubricants ( oleic acid for non-leafing pigments and stearic acid for leafing pigments), otherwise the risk of a dust explosion is. In the case of brass pigments, dry grinding is possible without any problems, since dust explosions do not occur due to the significantly higher density. After grinding, the white spirit is removed from the resulting mixture ( slurry ) using filter presses . In the last step, the filter cake is adjusted to the respective commercial form.

properties

Metallic effect pigments are around 20 micrometers long and up to one micrometer thick. They can only develop their effect if the parallel alignment in the paint film, both to each other and to the substrate and paint surface, is successful. Incident light is reflected on the surface of the effect pigment and scattered at the edges . The flatter the viewing angle, the more the effect of scattering predominates, so that the paint appears dark. At steeper viewing angles, on the other hand, the reflection predominates, so that the lacquer and thus the areas of the lacquer containing effect pigment appear light. The effect of the difference in brightness at different viewing angles is known as a brightness flop. If you see the individual pigment particles, this is called the sparkle effect . This effect is reinforced by the use of large pigment particles. In contrast to the pearlescent pigments, the pigment platelets are themselves opaque.

A colorimetric assessment is difficult because the brightness depends on the viewing angle. However, the development in the field of colorimetry has led to the fact that multi-angle measuring devices are now available, with which such an assessment can also be carried out by measurement. In 2000 standards were published for this.

An excessive shear stress in the dispersion can cause the platelets break down and no longer achieve the desired effect. Therefore, careful processing is necessary when incorporating effect pigments. In systems with low viscosity there is a risk of sedimentation . In this context, the commercially available pigment preparations are important, as they require less dispersion work.

Elemental aluminum reacts with water to form aluminum hydroxide and hydrogen . Since the effect is enhanced by the high surface area of the particles due to their platelet shape, the pigments turn gray. By using inhibitors or coatings (often made of silicon dioxide , aluminum oxide or polyacrylates ), which are applied by modifying the Hall process, so-called gas-stable aluminum pigments can be obtained.

Applications

In the 19th century, "bronzes" were used to replace the expensive poliment gilding in the industrial manufacture of picture frames. Shellac served as a binding agent and linseed oil was also used. To prevent oxidation, an additional clear coat is usually important. In the do-it-yourself sector, historical, even real gold-plated frames are often "refreshed" with metal pigment, which is then difficult to remove in the restoration.

Metallic effect pigments have been used in paints, especially in automotive paints, since the 1920s. Metallic effect pigments are also used in powder coatings , but there are some restrictions. In addition to this main area of application, the pigments are used in plastics, printing inks and cosmetics.

List of the metallic effect pigments listed in the Color Index

All metallic effect pigments listed in the Color Index are listed below. According to more recent editions of the Color Index, CI Pigment Metal 3, 4 and 5 are no longer available.

| Generic name | Constitution Number | Base metal / alloy |

|---|---|---|

| CI Pigment Metal 1 | CI 77000 | aluminum |

| CI Pigment Metal 2 | CI 77400 | Copper , bronze |

| CI Pigment Metal 3 | CI 77480 | gold |

| CI Pigment Metal 4 | CI 77575 | lead |

| CI Pigment Metal 5 | CI 77860 | zinc |

| CI Pigment Metal 6 | CI 77945 | tin |

Individual evidence

- ↑ a b H. Römpp: Römpp Lexikon Lacke und Druckfarben . Thieme, Stuttgart 1998, ISBN 3-13-776001-1 , p. 378.

- ↑ a b Ceresana Research: Pigments market study. Volume I.

- ↑ a b c d e f g H. Kittel, J. Spille: Textbook of paints and coatings. Volume V: Pigments, Fillers and Colorimetry . 2nd Edition. Hirzel, Stuttgart 2003, ISBN 3-7776-1015-1 , pp. 130ff.

- ↑ U.S. Patent 3002891.

- ↑ The name of this pigment property results from en: leaf for leaf, also leaflet

- ↑ a b c Arthur Goldschmidt, Hans-Joachim Streitberger: BASF Handbook Painting Technology. Vincentz Network, Hannover 2002, ISBN 3-87870-324-4 , p. 164.

- ↑ Ralf Glausch, M. Kieser, Roman Maisch, G. Pfaff, J. Weitzel: Pearl luster pigments . Vincentz Verlag, Hannover 1996, p. 13.

- ↑ a b c d e f g Gerhard Pfaff: Special effect pigments: Basics and applications . Coating technology. 2nd Edition. Vincentz Network, Hannover 2007, ISBN 978-3-86630-895-4 .

- ↑ DIN 6157, part 2

- ^ Color Index. Retrieved May 21, 2013 .