Gauge block

Gauge blocks are blocks yet to 1500 mm in length, for testing and calibration of measuring instruments and testing equipment or serve as secondary standards for directly measuring . They are made of steel , hard metal or ceramics and embody a certain length with a high degree of accuracy ( measuring standard ). Gauge blocks are available in different forms, for example as parallel , angle , spherical or cylinder gauges .

Gauge blocks are mostly sold in sentences with different lengths and gradations, so that one usually speaks of the plural gauge blocks .

history

The gauge blocks were invented by the Swede Carl Edvard Johansson . He worked in the state arms factory Carl Gustaf and dealt with the high costs of measuring the Remington rifle , since a new measuring gauge had to be made for each new length . When Sweden 1894 Mauser - carabiner introduced, Johansson was very interested in an analysis of the measurement methods Mauser. A visit to the Mauser factory in Oberndorf , however, resulted in a disappointment. On the way home, Johansson pondered the problem and came up with the idea of combining several individual gauges to minimize the number of gauges required. For example, any length between 1 mm and 15 mm can be formed from a combination of the four gauges with lengths of 1 mm, 2 mm, 4 mm and 8 mm (length in steps of 1 mm each).

Johansson found that with a little fat , the blocks stick together when the surfaces of two opposite sides are very flat and parallel. The width of this connecting layer was approximately 25 nm , which was so small for the tolerances at the time that the blocks could be adhered to one another without corrections. Ultimately, the connection layer was defined as part of the block so that any number of blocks could be put together without compensation.

At home, Johansson converted his wife's sewing machine into a reaming and lapping machine . His wife made the first sets at home. When Johansson presented his development to his employer Carl Gustaf , he gave him the time and resources to further develop the idea. In 1901 he had his idea patented .

In the United States, the idea was enthusiastically taken up by Henry Ford . Eventually, the use of gauge blocks was accepted as the most important method of transferring length in the industry . By the beginning of World War I, gauge blocks were so important to American industry that the government had to take steps to maintain supplies. Since the only supply came from Europe, this was interrupted after the outbreak of war.

In 1917, inventor William Hoke proposed to the NBS (National Bureau of Standards, now the National Institute of Standards and Technology ) a method for producing gauge blocks that was comparable to that of Johansson.

Funding was then provided by the Artillery Department to produce 50 sets of 81 blocks each for the NBS. These blocks were cylindrical with a hole in the middle, which was one of the most distinctive features of the design. Gauge blocks with these holes are known as hoke blocks .

Gauge blocks

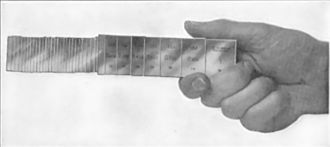

Gauge blocks are cuboid blocks with a very high length accuracy. Thanks to their high surface quality, they can be put together in different lengths at the ends by being held together by the adhesive force . The assembly is called pushing or wringing . Steel gauge blocks should be separated from one another after eight hours at the latest, as they tend to weld cold .

Gauge blocks represent the linear measures with the smallest measurement uncertainties . When calibrating in a National Metrological Institute (NMI), measurement uncertainties of around 20 nm to around 50 nm are achieved. The German NMI is the Physikalisch-Technische Bundesanstalt (PTB) in Braunschweig.

A standard set of gauge blocks, as used in many metalworking workshops, consists of five rows with nine gauge blocks each. The following table shows the series and their gradations.

| line | Final dimension length (in mm) | Gradation of the blocks (in mm) |

|---|---|---|

| 1 | 1.001 - 1.009 | 0.001 |

| 2 | 1.01 - 1.09 | 0.01 |

| 3 | 1.1 - 1.9 | 0.1 |

| 4th | 1 - 9 | 1 |

| 5 | 10 - 90 | 10 |

Not all possible lengths can be combined with this standard set because none of the gauge blocks is shorter than one millimeter. A length of 2.217 mm would therefore not be able to be mapped with this standard rate: For a combination of 217 µm, at least three individual gauge blocks are required in any case, so that the length of the gauge block combination will always exceed a length of 3 mm.

Because of the total deviation, which is made up of the dimensional deviation of each individual gauge block, combinations of gauge blocks should consist of as few individual gauge blocks as possible.

Angle gauges

Similar to lengths, there are dimensional standards for angles that are similar to gauge blocks, which, by combining between 0 ° and 90 ° in steps of at least 1 second, allow any angle to be put together for special designs. The assembly is handled in the same way as with gauge blocks, namely by pushing the measuring surfaces. This means a significant simplification of the measurement of angles, cones and angle divisions. The angle gauge blocks can be pushed together either additively or subtractively, as described below.

Example 1:

Target angle: 33 °

Required angle gauge blocks: 30 ° and 3 °

The 3 ° gauge block is pushed with the positive side against the plus side of the 30 ° gauge.

Example 2:

Target angle: 44 ° 30 '

Required angle gauge blocks: 45 ° and 30'

The 30 ' gauge block is pushed with the minus side against the plus side of the 45 ° gauge.

Thus it is possible to set degrees, minutes and seconds in any combination exactly and quickly. An angle gauge block with 16 angle gauge blocks allows around 35,000 angle combinations in the range of 0–90 ° in special steps of 1 second.

Tolerance of nominal angle ± 2 ″

angle gauge blocks : 1 ″ to 90 ° available

Design

Cross-section 50 × 9 mm

hardened and aged steel, ground and lapped

Step gauges

Step gauges also represent a measure of length. They have several measuring surfaces on a straight line , so that different lengths can be represented with one standard . They typically consist of a supporting body and bodies with plane-parallel surfaces fastened therein . The bodies can also consist of gauge blocks. Step gauges are often used to calibrate and test measuring machines such as 3D coordinate measuring machines.

Materials

- Steel gauge blocks are the most common because they meet most requirements and are inexpensive. The high maintenance requirement has a disadvantageous effect on handling.

- Gauge blocks made of carbide have a 20-fold higher wear resistance, but a 50% lower thermal expansion than steel, which leads to measurement errors due to different thermal expansion coefficients at temperatures outside the standard temperature of 20 ° C if the test objects are made of steel.

- Gauge blocks made of ceramic have a very high wear resistance, a steel-like thermal expansion and a low weight. In addition, they do not require any special care.

standardization

Gauge blocks are standardized according to DIN EN ISO 3650 and are produced in four tolerance classes, which can be assigned to the following application groups:

| class | application |

|---|---|

| K | Gauge block reference standards, these are mainly used to calibrate other gauge blocks |

| 0 | Calibration of other gauges and measuring devices in the air-conditioned measuring laboratory |

| 1 | Most used working standard in the measuring room for checking gauges and setting measuring devices |

| 2 | Mostly used working standard in production for testing gauges and for setting measuring devices |

Web links

- The Gauge Block Handbook . (PDF; 1.22 MB) National Institute of Standards and Technology (NIST) Gauge Block Guide (English)