Swing axle

The pendulum axle (also swing axle ) is a simple form of independent wheel suspension on automobiles . It resembles a rigid axle divided in two halves . The connection of the wheels with the respective half is the same as with a rigid axle. The two halves are swing arms ( pendulums ) mounted in the middle of the vehicle so that they can rotate transversely to the direction of travel . The two pivot bearings are close to each other ( two- joint pendulum axle) or coincide in one ( single- joint pendulum axle). During compression and rebound, the camber of the wheels and the track width change .

Edmund Rumpler received patent protection for this type of wheel suspension as early as 1903, but did not apply it to the teardrop car until 1921 .

Under swing axle is also understood:

- a usually unsprung rigid axle that can be rotated in the middle around the longitudinal axis of the vehicle (rear axle of forklifts , front axle of tractors ),

- a double axle (tandem axle) in which two wheels on one side of the vehicle, which are arranged one behind the other, are connected to a swinging longitudinal member

technology

In the case of driven pendulum axles, the differential gear can be permanently connected to the chassis (two-joint pendulum axle, universal joints at the differential output), or it is shifted laterally as part of one of the two semi-pendulum axles and pendulum-mounted in a fork-shaped receptacle attached to the vehicle body (single-joint pendulum axle) . The other semiaxis is driven by a cardan joint . With the single-jointed, "jointless pendulum axle" design according to Rumpler, the bevel gears (crown gears) roll on pinions built into the vehicle.

The high roll center causes a “disproportionately large change in track width” during compression , while the short pendulum half-axles cause a change in camber, which reduces driving safety. When cornering, the joint on the outside of the bend is raised (" propping up " the vehicle body), the outer wheel gets a positive camber, so that the tire lateral guidance decreases. In addition, the track width is reduced and the support base, which is important for cornering, becomes smaller. “The stronger the positive camber is when driving straight ahead and the harder the rear axle is reciprocating, the sooner this effect occurs when cornering. A post-outside-hiking the tail can be the result - so a lot of oversteer - and in extreme cases, a vehicle rollover. " Reciprocal spring rate can be explained by the combination of softer suspension springs with an effective only when gleichsinnigem deflection compensation spring out. This measure has the opposite effect of a stabilizer . It reduces the vehicle's tendency to oversteer by shifting the rolling moment from the rear axle to the front axle. In addition, the propping effect is somewhat reduced.

The change in camber is reduced by making the axle halves as long as possible (on the single-joint pendulum axle up to the middle of the vehicle; with non-driven axles also pendulums that are longer than half the vehicle width). The change in track width is less when the axle halves are hinged lower.

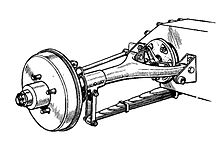

Pendulum axles can manage with a broadly supported pendulum joint without additional guide parts (adjacent figure). More often they are supplemented by trailing arms, like the one at Mercedes, or by flat-profile trailing arms like the VW Beetle . Its “spring struts” are torsionally flexible, only rigid around the axis of rotation in order to be able to transfer the torque from the wheel load to the torsion bar.

use

The swing axle is one of the early independent wheel suspensions. The name describes the semi-axes suspended "pendulum" in the transverse plane. It was suitable for vehicles with rear-wheel drive and central tubular frames. In 1923 the Tatra 11 appeared with a "jointless pendulum axle" based on the Rumpler system. The axle tubes were connected to the central tube frame at a common pivot point. Two-joint pendulum axles, like those already featured in the Rumpler Teardrop Car , also came into series production in the Mercedes-Benz W 15 in 1931 . In the thirties, other manufacturers used the swing axle. Ferdinand Porsche began developing the Auto Union Type A racing car in 1932 , which was equipped with a two-joint swing axle as the rear wheel suspension. Auto Union entered the 750 kg formula with the Type A in 1934.

The VW Beetle , which was initially built in series from summer 1945 without a compensating spring , had the above mentioned for longitudinal guidance. "Spring strut". Each axle tube was mounted in a joint on the side of the transmission. The movement of the axle pendulum did not describe a flat sector of a circle, but a part of a cone shell. The axis of the cone went through the pivot point of the pendulum joint and the center point of the articulation of the “spring strut” on the torsion bar. In addition to the major camber and track width changes during compression, there is also a change in toe-in.

The high articulation of the axle halves was initially rated as an advantage of the pendulum axle, as it reduces the tendency to roll when cornering. As the driving dynamics requirements increased, measures had to be taken to counter the tendency to oversteer due to the large rolling moment. In 1954, Mercedes-Benz lowered the pivot point of the single-joint swing axle of the Mercedes-Benz W 180 and added a compensating spring. The same design was followed by the Mercedes-Benz 600 in the luxury class in 1964 . The longitudinal guidance was taken over by trailing arms on which the air springs with level control were supported. For marketing reasons, the rear axle of the 1968 new Mercedes / 8 was called the " diagonal pendulum axle ", which was actually a semi-trailing arm axle . The pendulum axle of the S-Class ( W108 ), which was still being built, was not wanted to appear outdated.

Pendulum axles are typical for small cars from the 1930s to 1960s with a rear engine: They were used in the VW Beetle (not automatic and 1302/1303), in the Renaults with a rear engine ( 4CV , Dauphine , 8 , 10, Floride ), Trabant , in the Goggomobil also front, only front in the Hillman Imp , but also used in other classes ( Porsche 356 , Borgward Isabella , Mercedes 300 SL , Tempo Wiking , Tatra ).

Pendulum axles have been built in for more than forty years to adapt to different requirements: from small cars to luxury cars, driven and non-driven, on the rear and front axles. More recently, Tatra has been used in off-road trucks and Piaggio in Vespa Ape .

See also

literature

- Kurt-Jürgen Berger, Michael Braunheim, Eckhard Brennecke: Technology automotive engineering. 1st edition, Verlag Gehlen, Bad Homburg vor der Höhe, 2000, ISBN 3-441-92250-6

- Karl-Heinz Dietsche, Thomas Jäger, Robert Bosch GmbH: Automotive pocket book. 25th edition, Friedr. Vieweg & Sohn Verlag, Wiesbaden, 2003, ISBN 3-528-23876-3

Individual evidence

- ↑ Olaf von Fersen (ed.): A century of automobile technology, passenger cars . VDI-Verlag, Düsseldorf 1986, ISBN 3-18-400620-4 , p. 378 ( excerpt online , Google Books).

- ↑ Patent US1514862 : Rear-axle drive for motor vehicles. Registered on March 26, 1921 , published November 11, 1924 , inventor: Edmund Rumpler.

- ↑ [1] , double axle on a trailer, at the rear

- ↑ [2] , two-joint pendulum axle, lower picture, VW Beetle

- ↑ [3] , single-joint pendulum axle, schematic, top picture

- ↑ [4] , single-joint pendulum axle

- ↑ Archived copy ( Memento of the original from December 28, 2015 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Single-joint pendulum axle, sectional view, right semiaxis driven by cardan joint

- ↑ The differential cage and the bevel pinions driving the wheel shafts rotate around an axis parallel to the vehicle's longitudinal axis. When the semi-axles swing, the bevel ring gears on the wheel shafts roll on the bevel pinions by a small amount that is superimposed on the drive rotation. Differential gear on the single-joint pendulum axle at the back of the Pinzgauer : [5] (still image), [6] (video, function from around 2:00 minutes)

- ↑ a b Jörnsen Reimpell: chassis technology: wheel suspensions , Vogel Buchverlag 1988, pages 365-67

- ↑ Wolfgang Matschinsky: Wheel guides of road vehicles: statics, kinematics, elasto-kinematics and construction . 2nd Edition. Springer, 1998, ISBN 978-3-662-09653-6 , pp. 175 ( limited preview in Google Book search).

- ↑ [7] , single-joint pendulum axle at Mercedes