Reflectometric thin film measurement

The reflectometric thin-film measurement is a measurement method that is based on the principles of thin-film interference and is used to determine the layer thickness of dielectric thin films . The refractive index of the material can also be obtained from the data . This information is of increasing importance as thin films are widely used today, e.g. B. in anti-reflective coatings , the coating of medical implants or in the solar industry .

theory

A material layer whose two-dimensional expansion is several orders of magnitude greater than the layer thickness is referred to as a thin layer. Normally, thin layers with a thickness in the nano to micrometer range are used. Incident light is either reflected or transmitted at the boundary between material and surrounding medium (mostly air) ; the transmitted light in turn hits the interface between the thin film and the substrate and is again reflected here. How much light is reflected or transmitted can be determined with the help of the Fresnel equations . As a result, constructive or destructive interference occurs between the portions reflected at the two interfaces. This depends on the layer thickness , the refractive index of the material and the angle of incidence of the light. In addition, a phase shift of 180 ° or π can occur.

The optical path (OPD) of the incident light can be calculated using the figure as follows:

such as

After Snellius follows

and thus

With the reflectometric layer thickness measurement, the light from a white light source is directed perpendicularly onto the layer to be measured and the reflection is measured as a function of the wavelength with the aid of a spectrometer . From the above equation it follows that constructive interference occurs only for certain wavelengths and these wavelengths are directly dependent on the layer thickness and the refractive index.

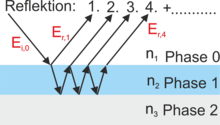

This results in a characteristic oscillation pattern , the frequency of which is directly dependent on the layer thickness. This pattern in the measured reflection is now derived. If you look at an electromagnetic wave that hits an interface, it is partially reflected and transmitted. In the case of a thin film, the transmitted wave hits an interface where transmission and reflection also take place. This process is repeated an infinite number of times, each time an electromagnetic wave is reflected from the thin film. To understand this mathematically, consider the following figure, in which the first four reflection processes are illustrated. The individual reflections can be described by the following four equations, where represents the amplitude of the incident electric field vector. The wave vector of the reflected waves is given by , the position vector by and their angular frequency is given by.

- 1. Reflection

- 2. reflection

- 3. reflection

- 4. Reflection

At each interface, the original amplitude of the incident wave is reduced according to Fresnel's equations. This is taken into account by the reflection and transmission coefficients, and . The subscriptions indicate the respective direction. The coefficient stands for the reflection of the incident wave at the 1st interface. This gives equations for an infinite number of reflected waves . If you look at the 4 equations presented for the first four reflections, you can see a pattern. The second reflected wave results from a wave that is first transmitted at the first interface, reflected at the second and finally transmitted again at the first interface. The resulting wave experiences a phase shift as can be seen in the exponential term. The phase shift results from the wave number and the optical path length. If there is also a phase jump at an interface, this must also be taken into account. Such a phase jump occurs when there is a transition from a low to a high refractive index and always has a value of . See Fresnel equations for more details . In summary, one obtains for the phase shift:

From the third wave on, there are also two reflections at the first and second interfaces, represented by and . Furthermore, the phase shift is multiplied. In order to only consider the reduction in reflection, a total reflection coefficient is defined .

Since the amount of the reflection coefficients is always less than one, the sum in the last equation is a geometric series . Thus the total reflection coefficient can be simplified as follows:

An expression for the total reflected wave at the first interface is thus obtained . The position vector is set here as a zero vector . Furthermore, due to the time reversibility of waves ( Stokes relation ), the two transmission coefficients at the first interface can be written down with the corresponding reflection coefficient .

The intensity of an electromagnetic wave is given by in a vacuum . Here is the dielectric constant of vacuum, the speed of light and and the electric and complex conjugate electric field strength. If one now assumes phase zero as a vacuum (or approximately air), this results in the reflected intensity.

The prefactor can be identified as the intensity of the incident radiation. So if you divide the last equation by this expression, you get the reflectance ; i.e. the percentage of the light that is reflected by the thin film system:

In the picture on the right, the determined reflection for thin film systems with the refractive indices 1, 1.5 and 2 is calculated in ascending order. The respective reflection coefficients were determined with the aid of Fresnel's formulas, whereby, as used in the reflectometric thin-film measurement, a perpendicular incident light beam was assumed. This means zero and the polarization no longer plays a role in the calculation. It can be seen that the number of minima and maxima increases if the layer thickness of the thin film (phase 2) is increased from 500 nm to 1500 nm. Furthermore, in the case of a 500 nm thick thin film, the intensity that is only caused by the first two reflected waves is plotted. The position of the minima and maxima remains unchanged if all reflection processes are taken into account. Every reflection process increases the effect of positive or destructive interference.

Evaluation of the measurement

In the description of the measuring principle it was shown that when measuring the reflection, a signal with minima and maxima depending on the wavelength is obtained. The position of the maxima of the reflectivity is given by the optical path length and the refractive index of the thin film. If you plot the inverse wavelength ( wave number ) as a function of the interference order , you get points through which you can lay a straight line. This can be seen from the equation for interference maxima derived in the previous chapter.

For constructive interference takes the value of whole numbers, for destructive interference takes multiples of 0.5. For the evaluation, both cases are combined to form the interference order. If one inverts the condition for interference minima and maxima one obtains:

Exactly this relationship is illustrated in the figure on the right. The value is obtained as the slope . If you know the refractive index of the thin film , you can calculate its thickness or, if you know the layer thickness, you can infer the refractive index. This is an idealized example. In reality, the refractive index of a material depends more or less strongly on the wavelength. This effect may have to be taken into account by fitting the measurement data with more complicated relationships.

literature

- Eugene Hecht: Optics. Addison-Wesley, 2002, ISBN 0-321-18878-0 .

- Olaf Stenzel: Optical Coatings: Material Aspects in Theory and Practice . Springer Series in Surface Sciences, 2014, ISBN 978-3-642-54062-2 .

Individual evidence

- ^ OS Heavens: Optical Properties of Thin Solid Films . Dover Books on Physics Series, 1991, ISBN 0-486-66924-6 .

- ↑ L. De Stefano, K. Malecki, FG Della Corte, L. Moretti, I. Rea, L. Rotiroti, I. Rendina: A microsystem based on porous silicon-glass anodic bonding for gas and liquid optical sensing . In: Sensors . tape 6 , 2006, p. 680-687 , doi : 10.3390 / s6060680 .

- ^ BR Marshall: Glue Film Thickness Measurements by Spectral Reflectance . In: Technical Report - National Security Technologies (United States) . doi : 10.2172 / 991875 .