Rafter roof

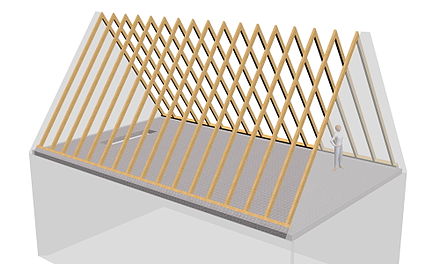

The rafter roof is one of the traditional roof constructions for making a pitched roof. Each two rafters are on the ridge to a rafter pair ( truss connected) and are supported on the beams, with the rafter triangle form. A rafter roof does not require any additional supports.

The simple wooden rafter roof is preferably built for small building depths of 7 to 8 meters and a roof pitch of ≥ 30 °.

A rafter roof is a little more complex to manufacture and erect than the purlin roof .

The collar beam roof is a special form of the rafter roof. The two rafters of a pair of rafters support each other by means of a horizontally extending collar beam . This allows larger spans and column-free building depths to be achieved. A collar beam roof is often provided with a roof truss , which however does not have to carry any permanent loads, but rather limits the deflection in the event of wind and one-sided snow load and is intended to provide the longitudinal bracing.

history

The rafter roof and the collar beam roof are considered to be the oldest forms of roof construction in Central and Northern Europe. In the course of the 19th century they were replaced by the purlin roof in Germany. Collar beam roofs were only built with the support of a standing chair . From around 1940 there were efforts to enable a simple and wood-saving construction method with the help of static calculations. In this context, the rafter and collar beam roof regained greater importance. After the Second World War, many single-family houses with collar beam roofs were built in Germany.

construction

The wooden rafter roof or collar beam roof consists of several pairs of rafters staggered one behind the other in the direction of the ridge . These pairs of rafters (rafters) together with a construction at the base of the rafters form a triangular frame. The distance between the individual frames can be between 70 and 80 cm and should not be greater than 90 cm.

With wooden rafter and collar beam roofs, two rafters are connected to each other at the ridge point, for example by a shear pin , a leaf or by straps mounted on both sides. To facilitate the installation of the rafters, one is in the ridge often topping wood built, such as a straight edge . This connects the rafter pairs in the longitudinal direction. For the actual longitudinal stiffening of the roof structure, however, wooden wind panes , wind pan straps made of metal, stiffening with diagonal shuttering boards or a roof truss with head straps are necessary. Standing roof trusses developed from work platforms that served as an aid when erecting the pairs of rafters and later took over the longitudinal reinforcement of the roof structure.

In traditional constructions, the ceiling beams were used as a horizontal connection and tie of the two rafter feet and in this function also referred to as distortion beams . More recently, a reinforced concrete floor has also served as the lower part of the triangular frame.

In the traditional construction, the rafter feet flow into horizontal wooden beams, which also form the ceiling. In the early Middle Ages, the horizontal forces were introduced into the tension beams through leaf connections, which were later replaced by tenon connections, which were finally replaced by an offset (with or without tenons). While a flush connection was carried out for the connection with a staggered tenon without offset, the ceiling beam usually protruded beyond the rafter in the case of tenon connections with an offset. This overhang is known as the forewood and is usually over 20 cm long. In order to be able to continue the roof covering over the wood, a slider is mounted on it, which has a lower incline than the rafter. This results in the characteristic kink in the roof covering over the eaves area of most traditional rafter roofs. Occasionally, however, the rafters were extended beyond the point of contact with the tension beams, so that the roof pitch ran continuously to the eaves, as with the purlin roof.

In newer constructions, a floor slab made of reinforced concrete serves as a tie for the triangular frame (as well as a ring anchor ). The wooden rafter feet lead to an upstand of the concrete ceiling or to the threshold or wall lath anchored in the ceiling . Sometimes the rafter or a partial cross-section of the rafter is guided over the edging and the building outer wall and forms the roof overhang . If the entire cross-section of rafter led beyond the support point, the force is introduced into the sleeper or in the upstand mostly over the lower side fixed to the rafters lugs .

Support system

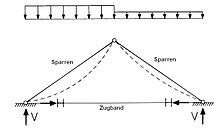

Rafter roof

With a rafter roof, the loads are borne exclusively by the rafters . These loads are then transferred to the eaves . The rafters' supports there must be fixed and immovable. A horizontal thrust occurs at the eaves, which is absorbed by the top floor ceiling (wooden beam or reinforced concrete ceiling). The amount of the resulting tensile force depends on the roof pitch. A rafter roof is therefore rarely used for roof pitches below 30 °.

The closed triangular shape is a prerequisite for the static function or for the load transfer of a rafter roof. This means that the rafters can only be interrupted, for example as a result of window openings, with increased structural effort in the form of so-called replacements . With a change, the rafters adjacent to the interrupted rafter (interchangeable rafters) are used for load transfer.

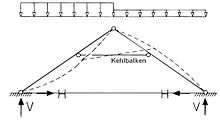

Collar beam roof

The collar beam roof is a special form of the rafter roof. The individual pairs of rafters are each connected by a horizontal collar beam. This construction reduces the deflection of the rafters under load. Larger spans or building depths can be realized than are possible with the simple rafter roof.

The collar beam position results in an additional level in the roof, which increases the usable area of the attic . When removing the roof, the collar beam layer can serve as the upper end of the attic . When determining the height of the collar beams, the room height of the resulting usable area must therefore be taken into account.

Collar beams were traditionally connected to the rafters using tenon joints or white tailed blades. Today they are mostly connected with straps or nail plates or performed as pliers .

Depending on the load-bearing behavior, a distinction is made between:

- Collar beam roof with movable collar beam

- Collar beam roof with immovable collar beam

Fixed collar beams are created by connecting the collar beams to one another. For example, a stiff disk (valley disk ) can be formed on the collar beam layer by means of boards or panels . In order to ensure immovability, this pane must then be anchored back in the gable or transverse walls or by a truss . Each pair of rafters is supported horizontally by the disc effect of the collar beam layer, so that the rafters form two-span girders . The collar beam roof with an immovable collar beam is an economical construction variant.

The collar beams can also be supported by chairs . If this happens in the middle, a single standing chair is created below the collar beam position. The horizontal bar under the collar beam is called a chair purlin or chair wall purlin . If each end of the collar beam is supported by a chair purlin, the result is a double-standing chair . Roof trusses are not primarily used to transfer the roof load from the collar beams. They ensure the transverse and longitudinal stiffening of the roof and accordingly support the roof in particular against wind loads or one-sided snow loads.

advantages and disadvantages

Compared to the purlin roof , rafter and collar beam roofs have the following advantages:

- No purlins are required.

- If a roof truss is not used, the result is a column-free roof space without posts that are supported on the ceiling below. With the floor plan, there is no need to take into account the loads introduced by the roof structure.

- The collar beams of a collar beam roof can be used for roof extensions. (With purlin roofs, additional transoms would have to be installed to form the ceiling or to create an additional, higher roof level.)

- With larger roof slopes, there is a comparatively lower wood consumption.

Disadvantages are:

- The horizontal forces to be supported at the base of the rafter only allow the formation of a jamb if complex support structures are provided in the eaves area.

- The horizontal forces to be absorbed make angular building plans and larger roof sections difficult. The horizontal forces must also be taken into account with hipped roofs.

- The erection of large dormer windows is problematic, they should not occupy more than two rafter fields.

- The beam is more complex.

References and footnotes

- ^ Sentence after Hagen Prehl: Wooden roof structures. 2nd edition, Düsseldorf 2001, Werner Verlag, p. 19.

- ^ Paragraph after Hagen Prehl: Wooden roof structures. 2nd edition, Werner Verlag, Düsseldorf 2001, pp. 18, 19.

- ↑ The term locked is traditionally not used uniformly in the specialist literature. This is how Tanja Brotrück relates: Basics roof construction. 2007, Birkhäuser, p. 19 in this context chevrons on the entire triangular frame.

- ↑ a b sentence after Tanja Brotrück: Basics roof construction. 2007, Birkhäuser, p. 19.

- ↑ a b c Stefan Holzer: Static Assessment of Historical Structures: Volume 2 - Wooden Constructions, P. 133ff, John Wiley & Sons, May 26, 2015

- ^ Theodor Böhm: Handbook of wooden structures . Verlag Julius Springer, Berlin 1911. (6th reprint edition of the original edition from 1911, Reprint-Verlag-Leipzig), p. 309

- ^ Paragraph after Hagen Prehl: Wooden roof structures. 2nd edition, Düsseldorf 2001, Werner Verlag, pp. 24, 25.

- ↑ a b c d sentence after Hagen Prehl: Wooden roof structures. 2nd edition, Düsseldorf 2001, Werner Verlag, p. 45.

- ^ Sentence after Günther Wasmuth (Ed.): Wasmuths Lexikon der Baukunst. Berlin, 1929–1932 (4 volumes), Lemma Stuhlwandpfette . "... the 16/18 to 18/20 thick purlins, which are used to support collar beams over 3.5 to 4 m long ..."

- ↑ a b List based on Hagen Prehl: Wooden roof structures. 2nd edition, Düsseldorf 2001, Werner Verlag, p. 17.