Wood connection

Wood connections are used in many different designs in the carpentry and joinery trade and are each provided with at least one technical term. They are mostly non-detachable, partially form-fitting connections .

history

The technique of joining wood is probably as old as human toolmaking . The splicing of hardwood - blade into a shaft was a primitive wooden connection. The transition to sedentarism led to the construction of permanent accommodation and the development of elementary wood connections. The oldest known wood connection is dated to about 5100 BC. BC ( Neolithic ). It was found during excavations near Eythra / Saxony (since 2005) on a wooden well socket combed from oak split planks.

Local craftsmen and craftsmen demonstrated high craftsmanship in handling stone axes and stone hatchets around 3500 BC. In the improvement of natural wood connections, e.g. B. by reworking branch forks, even more so with the early connections such as necks and tenons. With the beginning of the Bronze Age and with it the appearance of bronze axes and hatchets, the development of tools and with it the wood connections made a big leap forward. Correct saws made of toothed bronze leaves, also stretched in wooden hangers, have been around since 1500 BC. Proven in Egypt.

In the 15th century AD, the development from iron to steel had progressed so far that both a variety of specialized axes and hatchets could be made, as well as wide, hard saw blades. The wood connections that had been known as archaic types for thousands of years, such as tenons, leaves, combs, necks, claws and offsets, could quickly be further developed into a complex system of wood connections.

Basics

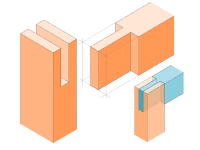

In a classic wood connection, two wooden parts are positively joined together. A spatial form is worked into each of the two wooden parts, which complement each other as a positive and negative shape. A third part is only used if the separation of the wood connection against the joining direction is to be prevented. In the simplest case, this is a nail or screw inserted across the joining direction, in the classic wooden connection a wooden pin or wooden wedges. In the carpentry trade, additional gluing is predominantly used , that is, an additional material bond .

In modern mass production, the complex individual shaping of the wood is being abandoned more and more. The parts have simpler connection surfaces and are connected using standardized additional parts. In addition to nails and screws, newly developed parts are used. In the carpentry trade, for example, these are metal plates that are nailed over the connection point or metal shoes into which the beams are inserted. Such solutions are called timber engineering connections .

In carpentry work, despite additional connecting elements, the old principle that the connection remains inconspicuous usually still applies. What is new is a contrary trend to emphasize visible connections and their elements as design components.

Joiner's wood joints

In the carpentry trade, wood connections mostly occur in furniture construction . Wooden parts to be connected are mainly boards to form corpus- like structures or to wider panels and strips to form frame-like structures. Some terms for carpenter-like wood connections are similar to those for carpentry-like wood connections, although the shape is similar or the same. One example is leafing through as leafing or overlapping .

The following terms are most commonly used. They are often used in connection with the common shape to be created from two parts in terms of geometry, appearance, function, etc. Ä. set. There are subspecies of many connection types with corresponding additional terms.

- Ridge connection, miter, prongs ,

- Overlapping, slot / tenon, bar / wedge, butt and others,

- Tongue / groove / rebate, shafts.

Carpentry wood joints

Carpentry-like wood connections are called the wood connections that are used in traditional wood construction to connect construction timber of larger cross-sections (larger 8 × 8 cm). They have come up with different wood construction, for example at carpenters roof constructions or the half-timbered house developed and are still in classic quality in the restoration used historic buildings, while more and more in commercial timber by joining techniques with the help of fasteners made of metal, plastic or laminated beams are replaced .

According to DIN 1052 Section 15, "carpenter-like connections for wooden components" are:

- 15.1 - offsets ,

- 15.2 - tenon joints ,

- 15.3 - Wooden nail connections .

Other carpenter-like wood connections are not regulated in the no longer valid DIN 1052. Eurocode 5 (EC 5) has been in force for timber construction since July 1st, 2012.

In a list according to the differentiation criterion of the connection type, the following connections are mentioned, for example:

- Butt joints ,

- Tenon joints ,

- Leaf connections ,

- Comb connections ,

- Neck joints

- Offset connections

- Claw connections

- Connections of block construction

- Connections of the bar structure / width connections

- Repair connections .

Subdivision and description of the joiner's wood joints

Butt, miter and overlap

In terms of geometry or appearance, most individual wood connections are either a joint, a miter or a lap.

- In the event of an impact , you can see from the outside that the end grain of one of the two parts, which are usually right-angled, hits the longitudinal timber of the other. The connection can be designed very differently, which is usually not visible from the outside. An additional connecting element can be used and remain hidden. Parts that collide on their end grain surfaces are not sufficiently tightly connected to one another. The end faces are, for example, cut at an angle (shank) and connected to one another via the resulting larger contact surfaces. Making long pieces of wood from two or more pieces is more common in the carpentry trade. Two boards that meet on the longitudinal timber result in a wider board, which also does not show how the connection is designed inside.

- A connection that joins at an angle is a miter if the longitudinal timber of both parts extends to the outside corner. In a plan view, both parts appear to be mitred (for example 45 ° for a right-angled connection). The miter cut does not have to be continuous. An additional connecting element can be used and remain hidden.

- In the case of overlapping , both parts are processed to about half their thickness at the connection point. The remaining material from both parts lies like two sheets on top of each other. Two parts with the same initial thickness are in the same plane after the connection. Overlapping is used both for angular (corner or cross lapping) and for extending straight connections. A related, but predominantly carpenter-like connection is the combing , whereby only one of the two parts or each part is processed to a small extent. The main purpose is to avoid that, for example, two bars lying on top of each other and crossing each other slip against each other.

- Butt, miter and overlap

Joint: Bonding reinforced with invisible flat dowels

Miter: Bonding reinforced with invisible micro-teeth (protruding tips are removed)

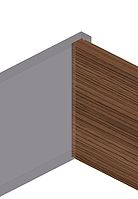

Groove and rebate connection

A groove can be the same width as the component to be inserted. Compared to a simple joint or a simple miter, there are three instead of just one contact surface, which means that the bonded connection can do without additional reinforcing fasteners. A narrower groove requires that the component to be inserted has to be processed in its thickness, for example a bung is created. If both parts are grooved, the connection is made by means of a spring to be inserted into both . The tongue and groove need not extend the full width or length of the parts. A shortened bung can be understood as a tenon .

A groove shifted to the edge becomes a fold with only two instead of three surfaces. In addition to gluing, a rabbet connection usually requires an additional connector

- Groove and fold

Narrow groove and board with machined bung

Tongue spring -groove compound

Board with fold ,

Mortise-tenon and web-wedge connection

A mortise in the form of a rectangular blind hole is referred to as a slot in wood connections . The slot accommodates the tenon , which is usually glued. Traditionally, the slot is chiseled into the wood with a chisel . Milled mortises have rounded corners that can be straightened with the chisel if desired.

Cylindrical mortises can be machined through a simple drill hole. The corresponding round tenon can be manufactured on the lathe . Alternatively, tenon holes can be drilled in both parts to be joined and connected with a loose tenon or wooden dowel .

A rectangular slot, open on three sides, forms, together with the pin, a stirrup pin corner connection

With a bar-wedge connection, the mortise is led completely through the wood. A longer pin "(web)" is pushed through the slot until it is flush with the other end. The end of the tenon is cut before assembly. To clamp the pin, small wedges are driven into the pin. By removing the wedges, the web-wedge connection can later be released again if it was not glued. In the past, this connection was often used in the manufacture of the door leaf of cassette doors. By driving in the wedges deeper or replacing them with stronger wedges, a hanging door leaf could be brought back into shape.

- Slot and tenon

Slot and tenon with miter on both sides

Pronging and ridging

Pronging is the most complex, but also the most appealing of the traditional wood connections. Since the sum of the bonded contact areas is large, it is also one of the most solid connections. It is mostly used to connect two boards at the corners, the end grain of which is cut out like a comb over the entire board width. Each prong of one part engages in the gap in the other part. Instead of a continuous joint, an alternating joint is created with each prong. On both sides of the corner edge, end grain and lengthways wood alternate across the board width.

As finger joints are called tines with straight faces. Either of the two boards can be pulled away from the corner (as long as the connection is not yet glued). Dovetail tines have an undercut . You cannot pull the boards with them away from the corner, in this direction there is a form fit . Movement is free perpendicular to the board (essential for joining). Since the bond with modern adhesives is more stable than the wood itself, glued straight finger tines withstand greater loads than dovetail tines , since the weak point on the narrow side of the dovetail tines is not present.

Prongs are also made half or even completely covered . This mainly applies to dovetail joints. The gaps between the tines are then no longer continuous slots as with open tines. When it is completely covered, a narrow strip of end grain can still be seen on one of the two boards. Only in the case of the concealed miter joint is no end grain visible.

A ridge has only one dovetail tooth and on the counterpart only one groove, the ridge groove . The undercut is usually kept smaller than with the usual dovetail joint with several teeth. The ridge can also be understood as a bung with non-parallel sheet pile walls. However, it is form-fitting and must be joined in the longitudinal direction of the ridge groove. The ridge groove has the same width in its bottom as the thickness of the ridged board.

- Finger and dovetail joint and ridge

Subdivision and description of the carpentry wood connections

The carpentry-like wood connections can be classified according to various criteria. Below is a list sorted according to the connection type criterion. The type of connection was chosen as a further sub-criterion; Longitudinal, corner, cross or cross connection.

Butt joints

In addition to the connections between load-bearing and supported timbers, i.e. all support connections, the joints - the lengthening of timbers in one direction or across a corner - were the forms of connection that were needed first. Such joints are necessary lying, in all inclines or standing. A rough breakdown using definitions can be the term shoe for lying pieces of wood and shanking for standing pieces of wood , whereby due to regional differences, these two terms are occasionally used reversed or interchangeably.

Longitudinal joints

- Butt joint / straight joint

- Angled push

- offset butt joint / offset straight joint

- offset oblique joint / half joint

- French oblique sheet / broken half joint

- (Blunt) joint with dovetail inlay at full height

- (Blunt) joint with dovetail inlay halfway up

Longitudinal joints with center piece

- Straight cut joint with inserted center piece

- Slanted joint with inserted center piece

- Straight cut joint with inserted hook

- Straight cut joint with inserted hook and wedges

- Slanted joint with inserted hook

- Slanted joint with inserted hook and wedges

- Straight cut joint with inserted double hook

- Straight cut joint with inserted double hook and wedges

- Slanted joint with inserted double hook

- Slanted joint with inserted double hooks and wedges

- Insert lock with security

Tenon joints

- Tenon joint

- French oblique blade with cones

- Dovetail tenons

Stocks

- Butt joint with oarlocks and building clips

- Butt joint with steel ring

- Cross joint with steel straps

- double stock

Corner joints

- Miter joint

Bumps across

- Joint with embedded wooden tabs

Tenon joints

Mortise and tenon joints are not only among the oldest connections with the leaves, but also one of the most widespread and varied types of wood connection. In order to understand the exact developmental stages of the cone, there is a lack of sufficiently early and dated or datable evidence. What is certain is that 3000 BC at the latest Wood connections in the form of "insert holes" (ie in full thickness in the wood to be connected to the wood ends), as ordinary tenons, but also square tenons that are staked on two sides.

Tenon joints

- Tenon joint

- French oblique sheet with tenons / joker tenon inclined on one side

- French oblique blade with tenon / French oblique blade with joke pin

- French oblique blade with tenon / oblique blade with parapet

- Dovetail tenon / continuous dovetail tenon

Scherzapfen, lengthways

- Scherzapfen / Scherblatt / tenon joint / utility pin

- One-sided inclined shear pin / slotted pin with undercut parapet

- One-sided obliquely incised shear pin / one-sided obliquely offset shear pin

- One side inclined shear pin / one side inclined slotted pin

- Shear pin inclined on both sides / shear blade inclined on both sides

- Shear pin / slotted pin cut at an angle on both sides with undercut parapet

- Angled shear pin on both sides / angled shear pin on both sides

- Shear pin inclined on both sides / slotted pin offset on both sides

- Scherzapfen with ridge / blade with ridge

- Joke pin with ridge / guide pin joint

- Joke pin with ridge / diagonally inserted joke pin with ridge on the joint

- Joke pin with a ridge / slotted pin with a ridge on the joint

Cone leaves

- Cone leaf / simple cone leaf

- Cone leaf / cone-shaped leaf with parapet

- Cone leaf / cone leaf joint

- Tenon blade / straight tenon joint with simple blade

- Cone leaf / step leaf

- Cone leaf inclined on one side / cone-shaped leaf with parapet inclined on one side

- cone leaf inclined on both sides / cone-shaped leaf with parapet inclined on both sides

- Dovetail cone leaf / dovetail-shaped leaf with parapet

- Dovetail cone leaf / dovetail with leaf

- Dovetail blade / dovetail blade joint

- dovetail cone blade incised on one side

- double cone leaf

- Straight blade with double tenons

- obliquely incised leaf Straight leaf with double cones

- Straight blade with double dovetail tenons

- obliquely incised straight blade with double dovetail tenons

Scherzapfen, across the corner

- Joke

- concealed joke pin

- one-sided miter pin

- Miter pin

- concealed miter pin

Dovetail tenons

- continuous dovetail corner tenon

- half-mortised dovetail corner tenon

Staked tenons

- tenon staked on one side / serrated tenon / axillary tenon / recessed tenon

- offset peg on one side

- Door post pivot

Straight tenons

- Straight tenon / simple straight tenon

- continuous straight tenon

- tenon staked on both sides / tenon boxed on both sides

- wedge-shaped driven pin

- Cross pin

- Double tenon

Pegs

- straight nipple / offset

- straight peg / straight peg with breast reinforcement

- straight nipple / simple straight nipple

- inclined nipple / inclined offset

Tenons with wedges

- Continuous straight tenon with wedges

- Straight tenon with keels

- half dovetail tenon with double wedge / soft tail tenon with double wedge

- Tenon lock / inserted tenon

- Mortise lock / push-through pin

- Tenon lock / tenon secured with split pins

- double mortise lock

Leaf cones

- flush simple leaf cone

- non-flush simple leaf cone

- double leaf cone

Inclined tenons

- oblique tenon

- Hunting cones

Spigot with offset

- Window bolt spigot

- Front offset with tenons

- Front offset concealed on one side with tenons

- double face offset with half tenon

- double face offset with tenon

- Heel offset with tenons

- heel offset concealed on one side with tenons

- Forehead and heel offset with tenons

- Offset with tenons in the continuous wood

Cones, crossed

- Side pivot

Leaf connections

A longitudinal connection is also known as a joint and can be a lapping (see joiner-like wood joints), a tenon (see joiner-like wood joints), hook lapping (left figure) or a purlin joint over posts .

A hook lap can be straight like a standard lap (see joiner-like wood connections) or at an angle like a shaft (see joiner-like wood connections). The purlin joint over the post is also called the tanner joint (figure on the right). With him, the hook of an oblique hook leaf has been omitted. Both connections do not transmit any bending moment , which is why they must be above a support (post) or close to it.

- Carpentry-like longitudinal connections

The carpenter-like corner joints are similar to the corresponding carpenter-like wood joints. A special feature is the oblique (French) overlay .

- Carpentry corner connections

Comb connections

Combs are usually connections in which crossing parts are not in one plane (first figure below). The parts are only cut to the extent that accidental mutual slipping is prevented. With joiner-like connections, they are also in the same plane (Figures 2 and 3).

- Carpentry-like and joiner-like combs

Cylindrical cut-out comb as a corner connection of a log house , parts lying on two levels

Dovetail-shaped comb, parts joined together flush; with an inclined connection (for example between collar beam and rafter ) and one-sided dovetail, also referred to as white tail blade .

struts of a headband combed in and secured with wooden nails

Combed connection

In log construction, one speaks of a combed connection when the ends of the timbers are not shortened flush, but protrude.

Combed connection

Unlike the combed connection, the combed connection shortens the ends of the timbers and thus closes them flush.

Neck joints

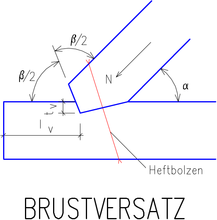

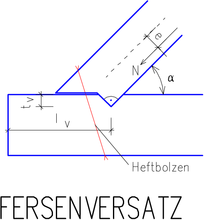

Offset connections

All (pressure-loaded) oblique connections are traditionally only in various stages of Versatzung run, which is a typical carpenter-made wood connection. The most important use is the offset in the traditional rafter roof . The inclined rafter beams are placed on horizontal ceiling beams ( offset ). The connecting offset is designed in such a way that, in addition to the bearing force, the thrust force acting outwards parallel to the ceiling joist is also absorbed by the ceiling joist.

The most important types of offset are:

- Front offset

- Chest offset

- Heel offset (back offset)

- The advantage is the automatically larger pre-wood length, greater distance between the incision and the face of the ceiling beam

- Double offset (forehead-heel offset)

The offset only absorbs the normal forces (here: compressive forces) of the rafter roof . This connection must be secured against lifting and shifting (sideways and inwards) (fastening bolt, pin, nail, screw).

Offsets can be covered on one or both sides, in that the connections do not extend to the edge of the wood into which they are offset.

- Offset types

Related terms or terms used synonymously with misalignment are stealing or kervung . A claw-like shape is created on the face of a beam that meets the edge of another. After a triangular incision, two “claws” remain at the edge of the forehead, which encircle the edge of the opposite beam.

Claw connections

Connections of block construction

Connections of the bar structure / width connections

The bung is related to the connection by means of two grooves and a spring. However, the tongue is not inserted as a separate element, but is worked out on one side of the pounded board on the milling machine. There is a groove on the opposite side.

- Straight bung

- Trapezoidal bung

Repair connections

If damaged beam pieces in a framework have to be replaced, the newly inserted pieces are usually connected to the remaining beam with a butt joint . To compensate for inaccuracies, the connection surfaces are often coated with a foaming PU wood glue, which increases the strength of the connection and at the same time fills gaps, so that the entry of liquid water into the connection point is reduced.

Wood connection with additional connection part

The classic wood connections are so form-fitting that they transfer the operating forces. In the normally force-free directions, they are often secured against accidental relative movements. In the case of carpentry-like connections, this is usually done through a third connection part, while joiner-like connections are usually glued for this purpose.

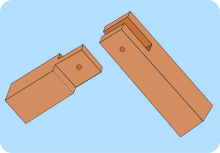

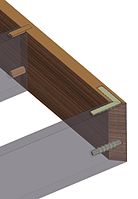

Wooden nail

For example, wooden nails are used to prevent a tenon from slipping out of the mortise, or a leaf or comb from lifting off. They are rounded or polygonal pieces of wood that are hammered into a pre-drilled hole in the wood connection. Depending on the application, these consist of particularly elastic ( sycamore , willow ) or hard wood. Nails sitting next to each other should not be arranged in the same plane in the wood, but offset in the direction of the grain so as not to encourage splitting of the beam by the spreading force of the nails.

As visible decorative nails , wooden nails can have a clean point and head.

- Wooden connection with an additional wooden nail

Two wooden nails in a tenon

Wooden nails in the half-timbered house from the Bandhaus, former cooperage and monastery cellar from 1478, Blaubeuren monastery

Metal nail, bolt or screw

Metal nails , bolts or screws largely replace wooden nails today.

In the carpentry industry, most of the classic wood connections can now be completely replaced by the use of nailed, screwed, bolted or clawed and pressed steel sheets.

In the simplest case, perforated metal sheets are nailed to the connection point from the outside. In order to make the metal connection less visible, sheet metal and metal shoes are pushed into slots in the beam and bolted from the outside.

Such solutions are called joins of wood engineering . They are not wood connections in the classic sense.

Dowel and spring

Dowels and springs are mainly used in the carpentry trade. They are primarily involved in the wood connection, because the two main parts to be connected usually only butt against each other without themselves entering into a form-fitting connection. Compared to the latter, the stability of the connections with dowels or springs is low. Your advantage is the low manufacturing costs on automated machines.

Dowels

Dowels are pieces of round wood, usually made of beech or ash, but also plastic, of different lengths and diameters. They are (generally) glued into holes with the appropriate diameter. The smooth or fluted dowels are most commonly used. The angle dowel is a modern form .

Flat dowels

A small piece of a tongue of the older tongue and groove connection is called a flat dowel or shaped tongue. The connection with it exists only in a few places, while the tongue and groove connection is continuous.

Tongue and groove

Two grooves and a tongue form the classic connection with an additional connecting part on the long sides of boards.

- Wood connection with additional dowel or additional spring

See also

- Fitting - connecting and securing elements for wood connections that are not made from wood alone

literature

- Hömmerich: wooden architecture. Traditional and modern wood connections. Rudolf Müller Verlag, Cologne, ISBN 3-481-13941-1

- Theodor Krauth, Franz Sales Meyer (ed.): Building and art carpentry . 2nd Edition. Seemann, Leipzig 1895, IV. The wood connections, considered in isolation. , S. 76-96 . Theodor Krauth, Franz Sales Meyer: The carpenter's book 1895 . Th. Schäfer, Hannover 1981, ISBN 3-88746-004-9 (reprint).

- Hans-Jürgen Schneider (Hrsg.): Construction tables for engineers . Werner Verlag

- Otto W. Wetzell (Ed.): Wendehorst - Structural number tables . Beuth Verlag, Berlin

Web links

- www.schreiner-seiten.de , work plans for conventional wood joints

- Video series "Joint Venture"

Individual evidence

- ↑ Stone Age beyond the stones . In: Spectrum of Science . March 2010, archeology, p. 62 ff ., quote p. 64 ( dendrochronologically dated to winter half-year 5098/97 BC).

- ↑ a b c d e Manfred Gerner: Handcrafted wood connections of the carpenters . Deutsche Verlags-Anstalt, Stuttgart 1992, p. 11 ff .

- ↑ a b c d e f Wood joints like a carpenter . (PDF) Associations of the Bavarian carpentry and timber construction trade.

- ^ A b Gary Rogowski: Wood connections - select, construct, build . Vincentz Network, Hannover 2011, ISBN 978-3-86630-951-7 .

- ↑ Wood connections on holz-technik.de

- ↑ connections on schreiner-seiten.de.

- ↑ DIN 1052: 2008-12, Section 15.

- ↑ Gary Rogowski: Wood connections - select, construct, build . Vincentz Network, Hannover 2011, ISBN 978-3-86630-951-7 , p. 226.

- ↑ Illustration see for example on www.schreiner-seiten.de.

- ↑ Stefan Holzer: Static Assessment of Historical Structures: Volume 2 - Wooden Constructions , p. 133, John Wiley & Sons, May 26, 2015

- ↑ a b carpenter techniques on burgseite.com, accessed on 23 August 2019

- ^ Alois Peyer: Architecture for the tropics , wood as material, 1.3.5. Stealings.

- ↑ Wolfgang Nutsch and others: expertise for carpenters (12th edition), published by Europa-Lehrmittel, Wuppertal 1980, page 175, ISBN 3-8085-4011-7 .