Sapwood

A split pin is a securing element in machine and vehicle construction . It is used to secure the position of connected components in a direction that is not the main load direction during operation. For example, (crown) nuts are secured against rotation or axes against displacement.

Commercial designation and classification

In the technical parts trade, split pins are usually not listed under securing elements , but under pins . Splintings are detachable connections .

Standard splint (EN ISO 1234)

|

|

DIN EN ISO 1234 |

|---|---|

| Area | Machine elements |

| title | Split pins |

| Latest edition | 1998-02 |

| ISO |

Standard split pins for general use are standardized in accordance with EN ISO 1234 . Before that, DIN 94 applied .

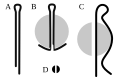

Split pins are made of wire with a semicircular cross - section . The two legs of different lengths are pressed parallel to one another and form a round cross-section with a diameter specified in the standard. At one end, the wire is compressed to form an approximately circular loop, the split pin head, which also has standardized dimensions.

Spring clip (DIN 11024)

|

|

DIN 11024 |

|---|---|

| Area | Machine elements |

| title | Spring clip |

| Latest edition | 1973-01 |

| ISO |

A cotter pin , in the vernacular also split pin , is a reusable-self-locking pin. Unlike the standard split pin, it does not have a split cross-section, but instead locks in place due to the elastic effect of the material. These split pins are standardized in DIN 11024.

Linch pin (linch pin, DIN 11023)

|

|

DIN 11023 |

|---|---|

| Area | Machine elements |

| title | Agricultural machines and farm tractors; Linch pin |

| Latest edition | 10.1979 |

| ISO |

For special requirements such as come from structural or safety special forms linchpins in accordance with DIN 11023 or Rohrklappsplinte in various designs used. In their basic form, they consist of a resilient steel bracket, which also includes nuts , bolts or screws , and a prism-shaped base body in which the wire bracket is pivotably mounted. The legs are interlaced with their own bracket when securing and thus act self-locking. Linch pins are often used to secure shafts and pipes, whereby the maximum permissible values for the surface pressure should not be exceeded: For linch pins according to DIN standards, maximum values of 350 N / mm² apply for pins with a diameter of up to 8 mm and 420 N / mm² for those with a diameter of up to 10 mm.

Special forms

There are also various, non-standardized sapwood shapes for special applications.

Materials

As materials of adequate strength, but tough come metals such as iron , steel or nonferrous metal - alloys (with or without surface coating) is used. Bare, tough steel is used most often. Spring steels are used for the self-locking split pins .

Use and handling of split pins

Since the material structure changes when securing and unlocking, standard split pins according to EN ISO 1234 may not be used again for safety reasons after assembly and disassembly . They have to be replaced with new parts. The diameters of the split pin and the associated hole ( split pin hole ) must be matched to one another. Together they form a game fit . The split pin must be easy to push through. After being pushed through, the legs are bent open (spread) against each other. They may be shortened by cutting them off. Under no circumstances is the use of split pins that are too short; the length should be approximately twice the length of the hole.

See also

Individual evidence

- ↑ Construction and tips Cotter pins on shaft ends ( Memento of the original from July 27, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Picture of different safety spring clips (Fokker needles) ( Memento of the original from December 21, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ www. Schrauben-lexikon.de ( Memento from September 9, 2013 in the Internet Archive )