Transparent wood

Optically transparent wood (TW) is wood that has been adapted through a chemical process , which is obtained by removing the strongly light-absorbing lignin component. The light transmission of 85% and the haze of 71% are comparable to frosted glass without affecting the structure of the wood.

Transparent cellulose fibers are used as a functional material for organic light-emitting diodes . The development of transparent lumber is in progress.

development

In connection with the introduction of OLED technology into the electronics industry, researchers succeeded in removing the light-absorbing lignin component from wood fibers. The organic cellulose nanofibers enable OLED technology to be more flexible. Among other things, the organic light-emitting diodes consume less energy than conventional LCD technology, as screens, for example, do not have a backlight.

In March 2016, Swedish researchers from the Royal Technical University used a chemical process to produce transparent wood samples without destroying the structure of the wood. Various magazines then reported on the transparent material and published pictures of the samples. In the future, transparent wood could play a role in construction.

Potential advantages in construction

Energy consumption in the building sector (including electrical lighting, air conditioning, cooling, etc.) accounts for around 30 to 40% of total energy consumption. Since this consumption increases with economic development, it is of great importance to reduce energy consumption in the construction sector. Solar energy is an attractive option because it is inexhaustible and clean. By increasing the light permeability of a building, artificial light can be replaced by natural light, thus reducing the need for electricity.

Wood is the most widely used biological building material and widely used in building. The origin from renewable raw materials is resource-saving and the good material properties such as low density, high toughness and high strength speak for centuries of use in construction. In addition, wood has a low thermal conductivity, which makes it interesting for use in passive house construction. Known methods of washing delignification of wood, i.e. the light-absorbing lignin, from the cellulose fibers are known from paper production . There, the cellulose fibers are extracted from the wood, the fiber diameter is reduced and water is added to make a paper pulp. In this process, the structure hierarchy of the cell structure is destroyed to such an extent that it can only be used in the construction sector for coatings. In order to obtain optically transparent wood without losing the material properties, chemical processes and adjustments in the nano range of the wood structure are necessary.

Manufacturing process

In order to be able to achieve a permeability of 85% and a haze of 71% with a wood thickness of 1.2 mm, the wood has to go through different production steps. After the process is completed, the result is examined for optical and mechanical properties. The reference object of the Swedish scientists at KTH is made of balsa wood . Balsa wood is a very light and easy-to-use type of wood. The density of the sample is 160 kg / m³.

Delignification

The delignification is a technical process to the light-absorbing lignin removed from the wood component to. In order to be able to remove the lignin from the wood fibers, a sample of balsa wood is first dried for 24 hours at 105 ± 3 ° C. The dried sample is then placed in a sodium chlorite (NaClO2) solution for 6 hours at 80 ° C until the lignin chains have broken. To remove or dissolve the small fragments, the sample is first washed with deionized water. Then treated with pure ethanol , followed by a 1: 1 mixture of ethanol and acetone and finally with pure acetone. This step is repeated three times to remove all of the lignin. Complete removal is crucial for the production of the optically transparent wood, as lignin is a strong absorbent and is responsible for 80 to 95% of the light absorption in the wood.

Manufacturing

The delignified wood (DLW) is not yet transparent due to the light scattering at the interfaces of the cell walls and in the air-filled cavities of the cell walls. Due to the high porosity of the sample, only a fraction of the light transmitted through the wood is not scattered. The refractive index of lignin is 1.61, whereas the refractive index of cellulose is only 1.53. (For example, water has a refractive index of 1.33.) The sample from which the lignin was removed had a refractive index of approx. 1.53. In order to regulate this, the sample is infiltrated with prepolymerized methyl methacrylate (MMA), which is intended to reduce the nanoscale porosity. When cured, the polymethyl methacrylate (PMMA) has a refractive index of around 1.49. Thus the light scattering has been reduced, which leads to almost complete light transmission and thus optical transparency.

For this purpose, the delignified balsa wood sample is infiltrated in a prepolymerized MMA solution in an oven at 70 ° C for 4 hours. A reaction then takes place by treating at 75 ° C. with pure MMA monomer . After 15 minutes, the reaction is terminated by cooling to room temperature with the aid of ice water. In order to ensure complete infiltration, i.e. the penetration or absorption of the solution into the balsa wood, the sample is treated again three times for 30 minutes each time with a prepolymerized MMA solution under vacuum. The polymerization process is then completed in an oven at 70 ° C. The acrylic glass-like methyl methacrylate is thus completely infiltrated and cured.

characterization

The result of the previous chemical processes is then checked. In order to examine the balsa wood sample for the content of lignin, the weight of the lignin present in the sample in grams is first determined using the TAPPI method. The percentage of lignin can now be calculated using the following equation.

where m [g] is the mass of lignin and M [g] is the oven-dry mass of the sample.

According to the previous characterization, the KTH sample shows a sharply reduced lignin content from 24.9 to 2.9%. After delignification, the originally brownish color of the balsa wood results in a cloudy, almost white color. However, under the microscope you can see the well-preserved honeycomb structure in the center of the wood sample, which was not affected by the chemical process.

Transparency and turbidity were determined with the aid of a transmission spectrum and the associated Haze method (ASTM D1003). For samples with a thickness of 0.7 mm, permeability values of 90% were achieved. When the thickness was increased to 3.7 mm, the transmittance decreased to about 40%.

Mechanical properties

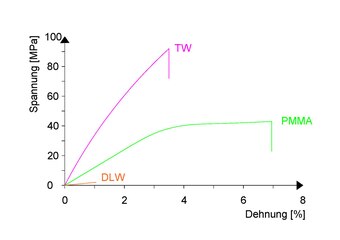

If the wood is used in construction, attention must be paid to the mechanical properties. The tensile stress-strain curve of the materials transparent wood (TW), delignified wood (DLW) and polymethyl methacrylate (PMMA) is shown in the diagram on the right. The modulus of elasticity of transparent wood (TW) is 2.05 ± 0.13 GPa, significantly higher than that of the delignified sample (DLW) (0.22 ± 0.08 GPa ). This is a result of the composite of polymethyl methacrylate (PMMA) (1.80 ± 0.18 GPa ) and the low density of the balsa wood (160 kg / m³). The low compressive and tensile strengths of balsa wood due to the coarse porosity and the resulting lack of load transfer mechanisms have been significantly improved by MMA infiltration and polymerization in PMMA.

Possible areas of application

Optically transparent wood could meet requirements comparable to construction timber due to the good and partially improved material properties and the unchanged structure . This could open up new possibilities for wood construction , both indoors and outdoors. For example, in the future, transparent wooden wall elements could become an inexpensive alternative to frosted glass or glass blocks . The window frames , which are becoming increasingly massive for reasons of thermal insulation, could also be made of transparent wood in window production, which would reduce the shading in the interior caused by the frames.

The high cloudiness of the transparent wood makes it attractive for solar cell applications . The light is trapped in the solar cell for a long time due to the light scattering through the wood fabric. This results in a better interaction between light and solar cell, which leads to a better efficiency of the solar cell.

Individual evidence

- ↑ Okahisa, Y .; Yoshida, A .; Miyaguchi, S .; Yano, H .; Optically transparent wood-cellulose nanocomposite as a base substrate for flexible organic light-emitting diode displays; 2009; doi: 10.1016 / j.compscitech.2009.04.017

- ↑ Prigg, M .; Scientists create transparent wood: superstrong material could replace glass in windows and even cars; Dailymail.com; May 17, 2016 ( available online )

- ↑ Callahan, D .; Wooden windows? New material could replace glass in solar cells and buildings; KTH / research news; March 31, 2016 ( available online)

- ↑ Wörn, S .; Transparent wood: is that the window pane of the future ?; Galileo.tv/science; April 1, 2016 ( available online)

- ↑ Nejat, P .; Jomehzadeh, F .; Taheri, MM; Gohari, M .; Majid, MZA Renewable Sustainable Energy Rev. 2015, 43, 843– 862, doi: 10.1016 / j.rser.2014.11.066

- ↑ Hegger, M .; Sustainability certification in construction - state of affairs and deficits, 2016, doi : 10.1007 / 978-3-658-09701-1_38

- ↑ Szerman, M .; Simplified determination of the light switch-on times for daylight-dependent regulated lighting using the daylight quotient, FRAUNHOFER INSTITUTE FOR BUILDING PHYSICS (IBP); 1994; IBP Notice 262

- ↑ Stark, J., Wicht, B .; History of Building Materials - 9. Wood; 1998, doi : 10.1007 / 978-3-322-92892-4_9

- ↑ a b c d e f g h Li, Y .; Fu, Q .; Yu. S .; Yan, M .; Berglund, L .; 2016, In: Optically Transparent Wood from a Nanoporous Cellulosic Template, KTH Royal Institute of Technology, SE-10044 Stockholm, Sweden; ( Available online )

- ↑ Wolpensinger. H; Life cycle assessment: Points with the plus energy house wood; 15th International Timber Construction Forum; 2009 ( available online )

- ↑ wasser-wissen.de/abwasserlexikon/d/delignifikation, accessed on May 14, 2016 ( available online )

- ↑ Yano, H .; Hirose, A .; Collins, P .; Yazaki, YJ Mater. Sci. Lett. 2001, 20, 1125-1126, doi: 10.1023 / A: 1010992307614

- ↑ Müller, U .; Rätzsch, M .; Schwanninger, M .; Steiner, M .; Zöbl, HJ Photochem. Photobiol., B 2003, 69, 97-105, doi: 10.1016 / S1011-1344 (02) 00412-8

- ↑ Zhang, Q .; Myers, D .; Lan, J .; Jenekhe, ZA; Cao, G. Phys. Chem. Chem. Phys. 2012, 14, 14982-14998, doi: 10.1039 / c2cp43089d

- ↑ Fink, S. Holzforschung 1992, 46, 403– 408, doi: 10.1515 / ed. 1992.46.5.403

- ↑ TAPPI T 222 om-02, Acid-insoluble lignin in wood and pulp. 2002-2003 TAPPI Test Methods; Tappi Press, 2002.

- ↑ ASTM Standard test method for haze and luminous transmittance of transparent plastics. ASTM D1003-00; ASTM, 2000.

- ^ Moon, RJ; Martini, A .; Nairn, J .; Simonsen, J .; Youngblood, J. Chem. Soc. Rev. 2011, 40, 3941- 3994, doi: 10.1039 / c0cs00108b

- ^ Van Lare, C .; Lenzmann, F .; Verschuuren, MA; Polman, A. Nano Lett. 2015, 15, 4846– 4852, doi: 10.1021 / nl5045583

![{\ displaystyle {\ text {Lignin}} = {\ frac {m [g]} {M [g]}} \ cdot 100 \, \%}](https://wikimedia.org/api/rest_v1/media/math/render/svg/9b53497966d17c9eaf6982502a814827f8324457)