Measuring resistor

A measuring resistor is an ohmic resistor that has to meet special requirements for tasks in measurement technology .

Measuring resistors are used as measuring transducers for converting an electrical voltage into an electrical current or vice versa, and also in precise voltage dividers . They are therefore used to measure current or voltage.

Particularly tightly tolerated and stable types are also called precision resistors.

conditions

- Requirement: accuracy.

- Typically realized relative error limits : = 10 −3 … 10 −4 in the range 1 mΩ ≤ ≤ 100 kΩ.

- The Physikalisch-Technische Bundesanstalt (PTB) manages ≤ 10 −6 .

- Demand: independence from influencing effects through

- Measuring current (self-heating),

- Ambient temperature (external heating),

- Connection technology,

- Aging effects,

- Operating frequency.

- Requirement: No thermal voltage in contact with copper.

- With Manganin and Isaohm , a thermal voltage is created at a temperature difference of around 1 μV / K. In contrast, a value of around 50 μV / K applies to constantan .

Pure metals have a temperature coefficient of resistance on the order of magnitude

and are therefore unsuitable. The same applies to carbon film resistors with - (0.2… 1) · 10 −3 1 / K. Metal film resistors are available with (15… 50) · 10 −6 1 / K. Create special Cu-Mn-Ni or Cr-Ni alloys

- .

The self-heating should remain small for a low temperature influence; it depends on the power converted and the size of the surface for heat dissipation. For this purpose, the manufacturer specifies the maximum permissible current strength in order to keep sources of error such as self-heating or electromigration within limits. The load capacity of measuring resistors is often lower than that of other resistors of the same construction.

construction

Higher resistance measuring resistor

Higher impedance measuring resistors as a wire resistance or sheet resistance in thick-film technology or thin film technology made.

Wirewound resistors have an inductance that increasingly falsifies the resistance in the case of alternating currents with increasing frequency. By bifilar inductance coil is greatly reduced, however, increases the capacitance. The capacitance between the windings leads to an impedance that decreases with increasing frequency. Wirewound resistors have the best stability and the highest load capacity, but cannot be produced in all designs.

In contrast, film resistors, in particular thin film resistors, require better protection against environmental influences, are less resilient and in the past could not be produced with the required stability. In particular, the temperature coefficient and the voltage coefficient of the resistor are still a challenge today for high-value sheet resistors.

High-value resistors are used in voltage dividers , for example , or complete voltage dividers are manufactured on a substrate. This has the advantage that the error resulting from the temperature coefficient can be partially canceled out due to the spatial proximity of the partial resistors.

Film resistors can be induction-free and are manufactured for at least 400 kV.

At high voltages and high resistance values, the voltage coefficient of the resistance is important. It is of the order of magnitude , but is also less controlled with up to two powers of ten.

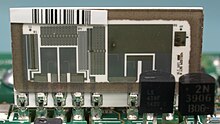

Low resistance measuring resistor

Low-ohmic measuring resistors, also known as current measuring resistors, shunt resistors or shunt , are made from sheet metal or rods of the alloys mentioned. The transition resistance of the contacts is a problem with these resistors . Is this z. B. 1 mΩ (depending on the material and corrosion it can be significantly higher and can also fluctuate), the following errors would result:

Example 1: For a measuring resistor of 1 Ω, two 1 mΩ contacts mean a relative measurement deviation of 0.2%. That is more than the typical error limit for resistance. This deviation cannot be viewed as negligibly small if the quality of the resistance is to be exhausted, nor can it be factored out because contact resistances can only be roughly estimated.

Example 2: Measuring resistor for converting 150 A into 60 mV, i.e. with R = 60 mV / 150 A = 0.4 mΩ with the same contact resistances: Relative deviation = 500%.

To avoid this deviation, current measuring resistors are connected using four-wire technology :

The current to be measured flows through the large, external power connections. The voltage drop across these has no effect on the measured voltage, as the voltage measuring device is connected to the small, internal terminals. Since only the low current that the measuring device needs flows through these, the contact resistances also present here only cause a negligibly small voltage drop.

With the very high currents, it heats up. In example 2, 9 W of heat flow are released in the measuring resistor at nominal current , and an additional 45 W. Thermal voltages can therefore falsify the measurement if the measuring terminals assume an unequal temperature.

Adjustable resistance

|

|

|

|

Resistance decade 10 × 1 Ω, bifilar wound tapes, step switch

|

Internal structure: 10 identical resistors and a switch with 11 positions 0, 1, 2,…, 10. Pos. 10 including the resistor may be missing depending on the version.

|

Adjustable resistors or potentiometers with sliders are unsuitable for measuring purposes if the setting range only extends over one revolution (270… 350 °). Special spiral potentiometers with a setting range of 10 revolutions create error limits in the linearity <0.3% and in the reading of the setting <0.1%.

Switchable resistance decades (decade resistances ) are used for precision measurements . A step switch as shown in the picture is used to select the resistance . They are produced in one device for a power of ten (e.g. 10 × 1 kΩ) or for several powers of ten (e.g. with 3 switches and 10 × 10 Ω + 10 × 100 Ω + 10 × 1 kΩ).

Other uses of the term

The term measuring resistor is also used for sensors for temperature measurement in platinum measuring resistors or for strain measurement in strain gauges . These are ohmic resistances, the resistance value of which, in contrast to the requirements mentioned above, depends on external influences such as temperature or mechanical deformation, so that this dependency can be used as a measuring effect .

See also

Individual evidence

- ↑ a b Development report in English

- ↑ http://www.high-voltage-resistors.net/index.aspx?pageid=610653&category=2727214&Page=2 website of Nicrom Electronic , accessed on May 25, 2019

- ↑ Wolfgang Gruhle: Electronic measurement: Analog and digital signal treatment. Springer, 1987, p. 95

- ↑ Data sheet for high-voltage precision resistors