Electromigration

Under electromigration (EM) is meant a material transport through gradual movement of ions in a solid conductor formed by the electric current is caused. Collisions of electrons with the ions and, to a lesser extent, the electric field exert a force on the ions, which is why they prefer to move in a certain direction during a diffusion step ( drift ). The practical importance of this effect increases as the structures are made smaller.

History of Electromigration

The phenomenon of electromigration has been known for more than 100 years. Major technical importance was the subject from about 1965, when it was discovered that in the then emerging integrated circuits ( ICs thin used) aluminum - strip conductors at high current densities are destroyed. The theoretical basis for explaining electromigration was established in 1961/62 in two articles by Huntington and Grone and Bosvieux and Friedel. James R. Black formulated a service life prediction for conductor tracks damaged by electromigration in 1966, see Black's equation . Back then, the conductor tracks were around 10 µm wide, while today's highly integrated chips are only around 14 nm wide. This area of research is becoming increasingly important, particularly due to this steady reduction in structure.

Practical importance of electromigration

Electromigration reduces the reliability of integrated circuits. In the worst case, it can lead to the total failure of one or more lines and thus to the uselessness of the entire circuit. Since the reliability of conductor tracks is of great importance not only in the fields of space travel and the military , but also in civil applications, such as the anti-lock braking system of cars, this effect is of great technological and economic importance.

With increasing miniaturization of high- and very large scale integrated circuits ( VLSI / ULSI ), the outage probability increases by EM, since both the power density and increase the current density. Although the required currents can be reduced by smaller structure sizes and operating voltages, since smaller transistors also have smaller gate capacitances, the currents are not reduced to the same extent as the conductor track cross-sections due to the increasing frequencies. Therefore, the required current densities and thus electromigration phenomena increase.

Instead of aluminum , in which electron migration occurs at around 500 kA / cm², most manufacturers have been using copper as a conductor path material since around the year 2000 . The advantages of copper are its better electrical conductivity (enables higher clock frequencies) and a current density load capacity that is around five times higher than that of aluminum, before EM phenomena occur.

A deliberately induced electromigration is used in the ultra-pure (> 99.99%) representation of the elements titanium , zirconium , hafnium , vanadium, etc. The elements are heated in a high vacuum to just below their melting point and foreign ions are removed from the center by electromigration, in which the element is now ultra-pure.

Basics

The material properties of the metal conductor tracks have a strong influence on the service life. These properties primarily include the composition of the conductor track alloy and the line dimensions, but also the line shape, the crystallographic orientation of the grains, the properties of the passivation and the interfaces with other materials. The process of layer deposition and heat treatments used in manufacture also affect the service life.

Serious differences also result from the course of the current over time: direct current or different alternating current forms each produce different effects.

Forces on ions in an electric field

Two forces act on the ionized atoms in the conductor . The direct electrostatic force results from the electric field and therefore points in the direction of the electric field. The force from the momentum exchange with flowing charge carriers points in the direction of the charge carrier flow . In metallic conductors is caused by a so-called "electron wind".

The resulting force on an excited ion in the electric field gives

An effective valency is introduced here. In it both direct forces and those forces that are generated by electrons at high speed are combined. With the elementary charge , the product represents the effective charge of the migrating ion. According to Ohm's law , the electric field is the product of current density and specific resistance .

The force is due to the shielding effect of the electrons, usually the dominant force; the force of the electric field on the ions, on the other hand, is relatively small. Activated metal ions are more likely to occupy a vacancy than other neighboring ions. As a result of this, metal ions move to the anode while voids move to the cathode . By compression of vacancies small voids ( English voids , voids ' ). This leads to open circuits due to material removal. Short circuits between conductor tracks, either through hill-shaped ( hillocks ) or filament- like structures ( whiskers ), result from the accumulation of ions on irregularities in the crystal .

Basic equations

Various experiments have shown that ions move in a constant field with a constant drift speed. The linear dependence of the current on rapidly moving electrons can generally be understood as a consequence of atomic diffusion, characterized by the intrinsic diffusion coefficient . In metals, free carriers with the charge are created by ionizations in the metal lattice. In this product is the effective valence of the ion. According to Nernst and Einstein , the mobility of ions (ion mobility ), which are only moved by an electric field, is described as follows:

In the equation is the Boltzmann constant and the absolute temperature in Kelvin . Thus the ions move with the mean drift speed of

The equation can be interpreted as the force on an ion through the field , which is balanced by microscopic frictional forces, while the average speed is.

Usually, the produced electrical resistance by collision of electrons with defects and lattice vibrations , known as phonons . These collisions transmit an impulse to the grid, which in turn increases the thermal speed of the electrons . The drift speed that results from this can be written as. The direct electrostatic force differs from the force caused by electrons at high speed, but it is the same microscopic forces that counteract them and thus determine the intrinsic diffusion and drift speed. Therefore you can combine the two effects and now get for the drift speed

The ion flow is defined by the product of the particle density and the mean drift speed.

If the last two equations are inserted into one another, one obtains with the help of Ohm's law for the ion flow and the intrinsic diffusion coefficient

According to the continuity equation, the change in particle density over time is the negative divergence of the ion current. With the last equation we now get

Under DC conditions we get div j = 0 for the continuity equation . Thus the second term on the right side disappears.

The diffusion coefficient depends negatively exponentially on the activation energy and the reciprocal of the temperature .

If you now insert the last equation into the penultimate equation, you can see that the ion flow also depends on.

is the activation energy in electron volts. These considerations are the basis for Black's equation .

The temperature dependence of Black's equation is called activated or Arrhenius behavior. The activation energy essentially indicates which is the main cause of failure. These findings are now fed back into the design process of the corresponding circuits, so that changes in the conductor track geometry, the conductor cross-section or the thickness of the passivation layers improve the reliability of the lines. For subsequent chip generations, this knowledge can also lead to the use of new material combinations that are less susceptible to electromigration.

Causes of failure

Diffusion mechanisms

One possible cause of failure is the diffusion of ions as a result of EM. This can be done by grain boundary diffusion, lattice diffusion and diffusion along heterogeneous interfaces or free surfaces.

Grain boundary diffusion

Because of the low activation energy, grain boundary diffusion is one of the most important mechanisms of the above-mentioned diffusion mechanisms. Mass flow through a homogeneous region as a result of EM takes place without the formation of “voids” or “hillocks”. The divergence of the ion flow, see equation, is zero. If, however, inhomogeneities occur in the material, the divergence of the ion flow is different from zero and macroscopic defects occur. The proportion of the ion flow due to EM at the grain boundaries is described by:

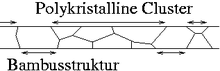

This equation is based on the ratio of the effective grain boundary width for mass transport to the average grain size . The quotient also results from the area of all grain boundaries and the total area of the conductor track. A decisive role for divergences in the ion flow are points at which three grain boundaries are adjacent, see figure on the right.

Since the mass flow along the grain boundaries into such a “triple point” is not equal to the mass flow out of this boundary area, divergence occurs. This is why “ voids ” and “ hillocks ” tend to be created at such borders. In the figure on the right, material is removed for the angle from and and added for material.

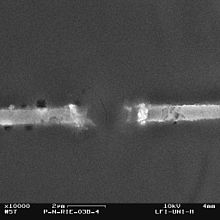

Attempts are made to counteract this effect by bringing the grain structures during metal deposition and heat treatment ( English annealing ) to the order of the conductor track width. This so-called “bamboo structure” minimizes the effect of grain boundary diffusion - the lattice diffusion predominates in the bamboo structures. In the course of miniaturization, grain boundary diffusion is therefore increasingly taking a back seat. Black's results show that, compared to fine-crystalline conductor tracks, the activation energy in conductor tracks in which the grain sizes are about half the size of the conductor track widths is almost doubled. The process for metal deposition has remained the same.

Grid diffusion

The activation energy for EM within the metal lattice is very high. This is due, on the one hand, to the high binding energy of the atoms in the lattice, and, on the other hand, to the lack of defects.

A decisive influence here has the crystallographic orientation of the atoms in the lattice: The EM lifetime of (111) from chemical vapor deposition ( English chemical vapor deposition, CVD ) discrete copper is 4-fold greater than that of (200) CVD copper.

Diffusion along heterogeneous interfaces

Interfacial diffusion occurs because of defects between the metal and the passivation layer, or barriers and free bonds between the metal atoms. The reason for this is poor adhesion between the two layers. The activation energy is therefore dependent on the materials of the conductor track and the passivation or barrier. Defects at the boundary layer favor mass transport and free bonds between the metal atoms reduce the activation energy.

Surface diffusion

A decisive difference was found between passivated and unpassivated conductor tracks. The activation energy has increased by almost 50% after the large-crystalline conductor tracks were provided with a silicon oxide passivation. The surface diffusion is suppressed by the passivation.

The average speed of the atoms on the surface caused by a constant electric force is

where is the surface diffusion coefficient. The mass transport on the surface consists mainly of diffusion and electromigration. The proportion that adsorption and desorption provide is negligibly small.

The surface diffusion depends on the orientation of the atoms in the crystal. The activation energy is significantly lower with a (111) alignment than with a (001) or (011).

The effective diffusion constant results from the sum of the individual constants of the four diffusion mechanisms.

The indices and stand for lattice, grain boundary, interface and surface diffusion.

Thermal effects

Joule self-heating

The high current density causes Joule self-heating, which causes a temperature increase in the test structures. Such an increase in temperature makes the interpretation of the data difficult since it leads to an offset of the predetermined conditions.

The mass transport is not only caused by EM, but also by thermomigration, which accelerates it further. The reason for self-heating is the power loss caused by the electricity . Increases of 5–10 ° C for single lines at = 1 · 10 6 A / cm 2 have been reported. The Joulean self-heating is particularly noticeable when several parallel lines are tested next to each other. With such arrangements, temperature increases of up to 200 ° C can occur, so the lines must be measured individually.

The following describes the physical relationships of self-heating: The metal temperature is given by

In this equation is the temperature of the metal, is the temperature of a reference chip, and the temperature rise caused by the flow of current. Under thermally stationary conditions, the temperature due to self-heating is described by the following equation

This is the effective value of the current, conductor resistance, the period, and the thermal impedance between conductor track and substrate . It is also assumed that the current frequency is significantly greater than the inverse thermal time constant. This in turn means that the metal temperature hardly fluctuates.

Thermal stress

Another cause of failure can be the occurrence of mechanical stresses due to thermal displacement between the metallic conductors and the substrate surface. This phenomenon is also called “stress migration” or “stress voiding”. Stress migration is directly related to EM.

further reading

- JR Black: Electromigration - A brief survey and some recent results . In: IEEE Transactions on Electron Devices . tape 16 , no. 4 , 1969, p. 338-347 , doi : 10.1109 / T-ED.1969.16754 .

- JR Black: Electromigration failure modes in aluminum metallization for semiconductor devices . In: Proceedings of the IEEE . tape 57 , no. 9 , 1969, p. 1587-1594 , doi : 10.1109 / PROC.1969.7340 .

- A. Christou .: Electromigration and Electronic Device Degradation. John Wiley & Sons, 1994, ISBN 978-0-471-58489-6 .

- DS Gardner, JD Meindl, KC Saraswat: Interconnection and electromigration scaling theory . In: IEEE Transactions on Electron Devices . tape 34 , no. 3 , 1987, pp. 633-643 , doi : 10.1109 / T-ED.1987.22974 .

- PB Ghate: Electromigration-Induced Failures in VLSI Interconnects . In: 20th Annual Reliability Physics Symposium, 1982 . S. 292-299 , doi : 10.1109 / IRPS.1982.361948 .

- PS Ho: Basic Problems for Electromigration in VLSI Applications . In: 20th Annual Reliability Physics Symposium, 1982 . 1982, p. 288-291 , doi : 10.1109 / IRPS.1982.361947 .

- G. Jerke, J. Lienig: Hierarchical current-density verification in arbitrarily shaped metallization patterns of analog circuits . In: IEEE Trans. On Computer-Aided Design of Integrated Circuits and Systems . tape 23 , no. 1 , 2004, p. 80-90 , doi : 10.1109 / TCAD.2003.819899 .

- BD Knowlton, CV Thompson: Simulation of the temperature and current density scaling of the electromigration-limited reliability of near-bamboo interconnects . In: Journal of Materials Research . tape 13 , no. 5 , May 1, 1998, pp. 1164-1170 .

- J. Lienig, G. Jerke: Current-driven wire planning for electromigration avoidance in analog circuits . In: Proc. of the 2003 Asia and South Pacific Design Automation Conf . ACM, New York, NY, USA 2003, ISBN 0-7803-7660-9 , pp. 783-788 , doi : 10.1145 / 1119772.1119946 .

- J. Lienig, M. Thiele: Fundamentals of Electromigration-Aware Integrated Circuit Design . 1st edition. Springer, 2018, ISBN 978-3-319-73557-3 , doi : 10.1007 / 978-3-319-73558-0 .

- HC Louie Liu, SP Murarka: Modeling of Temperature Increase Due to Joule Heating During Electromigration Measurements . In: MRS Proceedings . 427, Symposium K Advanced Metallization for Future ULSI, 1996, p. 113-119 , doi : 10.1557 / PROC-427-113 .

Web links

- Series of articles Electromigration - A new challenge in the design of electronic assemblies , published in Mechatronik F&M Magazin, C. Hanser Verlag, Munich, Part 1: pp. 36–39, Oct. 2002, Part 2: pp. 26–28, Jan./Feb . 2003, Part 3: pp. 12–15, March 2003:

- Part 1: Causes and influencing possibilities (pdf; 894 kB)

- Part 2: Current-dependent wiring of conductor tracks (pdf; 581 kB)

- Part 3: Calculation of current densities in conductor tracks of different geometries (88pdf; 615 kB)

- Textbook Fundamentals of Electromigration-Aware Integrated Circuit Design , published by Springer, 2018

- The enemy on the chip - electromigration in digital circuits , published in Elektronik Magazin, Weka Fachmedien GmbH, Haar, issue 2, pp. 32–36, Feb. 2012

- The SND syndrome electromigration: what is it? - Risks of overclocking CPUs with 0.13 µm structure width on Hard Tecs 4U

- What is Electromigration? Computer Simulation Laboratory, Middle East Technical University.

Individual evidence

- ↑ HB Huntington, AR Grone: Current-induced marker motion in gold wires . In: Journal of Physics and Chemistry of Solids . tape 20 , no. 1-2 , June 1961, pp. 76-87 , doi : 10.1016 / 0022-3697 (61) 90138-X .

- ↑ C. Bosvieux, J. Friedel: Sur l'electrolyse des alliages metalliques . In: Journal of Physics and Chemistry of Solids . tape 23 , no. 1-2 , 1962, pp. 123-136 , doi : 10.1016 / 0022-3697 (62) 90066-5 .

- ↑ JR Black: Electromigration - A brief survey and some recent results . In: IEEE Transactions on Electron Devices . tape 16 , no. 4 , 1969, p. 338-347 , doi : 10.1109 / T-ED.1969.16754 .

- ↑ heise online: Kaby Lake: Intel brings seventh generation of the Core-i processors . News dated August 30, 2016

- ^ J. Lienig: Electromigration and Its Impact on Physical Design in Future Technologies. In: Proc. of the International Symposium on Physical Design (ISPD 13). 2013, pp. 33-40 ( PDF ).

- ↑ a b c J. Lienig, M. Thiele: Fundamentals of Electromigration . In: Fundamentals of Electromigration-Aware Integrated Circuit Design . Springer, 2018, ISBN 978-3-319-73557-3 , pp. 13–60.

- ^ A b J. Lienig: Introduction to Electromigration-Aware Physical Design. In: Proc. of the International Symposium on Physical Design (ISPD 06). 2006, pp. 39–46 ( PDF )