Railway coupling: Difference between revisions

No edit summary |

GreenC bot (talk | contribs) Move 1 url. Wayback Medic 2.5 per WP:URLREQ#google.com/patents |

||

| Line 1: | Line 1: | ||

{{Short description|Mechanism for connecting rolling stock in a train}} |

|||

[[Image:Railroad coupler.agr2.jpg|thumb|300px|Knuckle (AAR Type "E") couplers in use]] |

|||

{{Other uses|Coupling (disambiguation)}} |

|||

[[Image:Tow hitch 5.jpg|thumb|right|200px|AAR Type "E" [[railroad car]] coupling]] |

|||

{{train topics}} |

|||

A '''coupling''' (or a '''coupler''') is a mechanism for connecting [[rolling stock]] in a train. The design of these couplings is a standard almost as important as the [[railway gauge]], since flexibility and convenience are maximised if all rolling stock can be coupled together. |

|||

[[File:St Pancras railway station MMB G3 395009.jpg|thumb|250px|[[Scharfenberg coupler]] on a [[Southeastern (train operating company)|Southeastern]] [[British Rail Class 395|Class 395]]]] |

|||

[[File:Scharfenberg coupler in action ICE Leipzig-short.webm|thumb|Video of [[ICE T]] coupling at [[Leipzig Hauptbahnhof]]]] |

|||

A '''coupling''' or '''coupler''' is a mechanism, typically located at each end of a [[rolling stock|rail vehicle]], that connects them together to form a train. The equipment that connects the couplers to the vehicles is the '''draft gear''' or '''draw gear''', which must absorb the stresses of the coupling and the acceleration of the train. |

|||

== Nomenclature == |

|||

Throughout the history of railroading, a variety of coupler designs and types have been developed worldwide. Key design considerations include strength, reliability, easy and efficient handling, and operator safety. Automatic couplers engage automatically when the cars are pushed together. Modern versions not only provide a mechanical connection, but can also couple brake lines and data lines. |

|||

The different types of coupling do not always have formal or official names, which makes descriptions of the couplings in use on any railway system problematic. |

|||

Different countries use different types of couplers. While North American railroads and China use [[Janney coupler]]s, railroads in the former [[Soviet Union]] use [[SA3 coupler]]s and the European countries use [[Buffers and chain coupler|screw couplers]]. Challenges and complications arise when coupling vehicles with different couplers. [[Barrier vehicle|Barrier cars]], also called ''match cars'', cars with [[dual coupling|dual couplers]], or adapters are used to accomplish this task. |

|||

== Buffers and chain == |

|||

==Nomenclature== |

|||

[[Image:European coupler on loco.jpg|thumb|Traditional buffer-and-chain coupler]] |

|||

Compatible and similar couplings or couplers are frequently referred to using widely differing make, brand, or regional names, or nicknames, which can make describing standard or typical designs confusing. Dimensions and ratings noted in these articles are usually of nominal or typical components and systems, though standards and practices also vary widely with railway, region, and era. |

|||

[[Image:Eisenbahn Schraubenkupplung 1.jpeg|thumb|Two cars coupled]] |

|||

[[Image:Chain coupler detail.jpg|thumb|Chain coupler detail (train in shunting mode)]] |

|||

[[Image:Coupler ride mode.jpg|thumb|Cars coupled in ride mode]] |

|||

The standard type of coupling on railways following the British tradition is the buffer and chain coupling used on the pioneering [[Liverpool and Manchester Railway]] of 1830. These couplings followed earlier [[tram]]way practice but were made more regular. The vehicles are coupled by hand using a hook and links with a [[turnbuckle]]-like device that draws the vehicles together. In Britain, this is called a '''screw coupling'''. Vehicles have [[buffer (rail transport)|buffers]], one at each corner on the ends, which are pulled together and compressed by the coupling device. This arrangement limits the slack in trains and lessens shocks. In contrast, [[#Janney coupler|Janney coupler]]s encourage violent encounters in order to engage the coupling fully. The earliest buffers were fixed extensions of the wagon frames, but later spring buffers were introduced. |

|||

Buff: when the consist (one or more cars coupled together) of cars is in compression; opposite of tension.<ref>{{Citation |title=Train Couplers 101 - How do train cars stay together? |url=https://www.youtube.com/watch?v=IEX6_GRk6sU |access-date=2023-04-17 |language=en}}</ref> |

|||

Inefficient and slow, the European system is relatively unsafe because it requires manual coupling between vehicles, exposing workers to the risk of being crushed. With central couplers (except link and pin) it is not usually necessary to get between the cars for coupling or uncoupling. The safety issue was one of the main arguments for changing to central couplers. After more than 30 years, the change has still not been completed; indeed it has barely started.{{Fact|date=March 2008}} |

|||

==Buffers and chain==<!-- Do not remove this because an unknown number of pages still redirect here --> |

|||

This coupling type is the standard in European countries (except the former Soviet Union, where the [[SA3 coupler|SA-3 automatic coupler]] is used). Coupling is done by a worker, who must climb between the cars. First he turns a releasing screw (an aid with two opposite windings, and it does not uncouple the train itself) to the loose position, and then he can hang the chain on the hook. After hanging the chain on the towing hook the releasing screw must be turned to the tight position. When the coupler is uncoupled, it must be hung on the idle hook to prevent damage to itself or the brake pipes. Only shunting is permitted with a dangling chain. Disconnected brake pipes must be hung on hooks. (The picture shows two coupled cars, with a single brake pipe.) |

|||

{{Main|Buffers and chain coupler}} |

|||

The hooks and chain hold the carriages together, while the buffers keep the carriages from banging into each other so that no damage is caused. The buffers can be "dumb" or spring-loaded. That means there are no run-in forces on the coupler. The other benefit compared with automatic couplers is that its lesser slack causes smaller forces on curves; there is a lower probability of a broken coupler in a curve than with automatic couplers. The disadvantage is the smaller mass of the freight that can be hauled by that coupler (maximum 3000 tonnes). |

|||

The basic type of coupling on railways following the British tradition is the buffer and chain coupling. A large chain of three links connects hooks on the adjoining wagons. These couplings followed earlier [[Plateway|tramway]] practice but were made more regular. [[Buffer (rail transport)|Buffer]]s on the frame of the wagon absorbed impact loads, as the train overran a slowing locomotive. |

|||

The simple chain could not be tensioned, and this loose coupling allowed a great deal of back and forth movement and bumping between cars, as well as jarring when trains started. While acceptable for mineral cars, this coupling made for an uncomfortable ride in passenger coaches, so the chain was improved by replacing the center link with a screw with a left-hand thread on one side and a right-hand thread on the other. In the center of the screw is the handle housing with a hinged ball handle attached. This [[turnbuckle]] style arrangement allows the vehicles to be pulled together by tightening the screw with the attached handle. Typically, the screw is tightened until there are two threads left next to the handle housing. A support is attached to the [[trunnion]] nut on the coupling link side to rest the handle of the screw to prevent loosening of the screw while the coupling is in use. The official name of this type of coupling is ''screw coupling'' or ''UIC coupling'' according to the [[European Standard|European standard]] EN 15566 ''Draw gear and screw coupling''. |

|||

Early rolling stock was often fitted with a pair of auxiliary chains as a backup if the main coupling failed. This made sense before the fitting of continuous fail-safe braking systems. |

|||

A simplified version of this, quicker to attach and detach, still used three links but with the centre link given a T-shaped slot. This could be turned lengthwise to lengthen it, allowing coupling, then turned vertically to the shorter slot position, holding the wagons more tightly together. |

|||

On railways where rolling stock always pointed the same way, the chain might be mounted at one end only, as a small cost- and weight-saving method. |

|||

Higher speeds associated with fully-fitted freight{{efn|A train with continuous brakes on all wagons.}} made the screw-tensioned form a necessity. |

|||

On [[rail transport in Germany|German railways]], one buffer is flatter than the other buffer, which is slightly more rounded. This provides better contact between the buffers than would be the case if both buffers were slightly rounded. |

|||

The earliest '[[dumb buffers]]' were fixed extensions of the wooden wagon frames, but later spring buffers were introduced. The first of these were stiff cushions of leather-covered horsehair, later steel springs and then hydraulic damping. |

|||

=== Buffers and narrow gauge === |

|||

This coupling is still widespread in Western and Central Europe and in parts of Northern Africa, the Middle East and South Asia.{{sfn|DAC Report|2020|p=7}} |

|||

With the exception of [[Queensland]] and [[Tasmania]], twin buffers and chains are rare on narrow gauge lines, perhaps because of the buffer locking problem on sharp curves. |

|||

<gallery mode="packed" heights="140px"> |

|||

File:Consett-tankwagon41 - buffer beam.jpg|Three-link coupling on an antique tank wagon |

|||

File:Eisenbahn Schraubenkupplung 1.jpeg|UIC standard screw coupling, shown attached and tightened |

|||

</gallery> |

|||

==Link and pin== |

|||

=== Three-link couplings === |

|||

[[File:Link and Pin.jpg|thumb|left|A link-and-pin coupler]] |

|||

[[File:Early Janney-type AAR coupler.JPG|thumb|Transition era AAR knuckle coupler. The gap in the knuckle accommodates the link of a [[#Link and pin|link and pin coupler]] and the vertical hole in the knuckle accommodates the pin.]] |

|||

[[File:08-130 Esclusas de Miraflores (23).jpg|thumb|Link and pin coupler combined with side buffers on a [[Panama canal mule]].]] |

|||

The link-and-pin coupling was the original style of coupling used on North American railways. After most railroads converted to semi-automatic [[Janney coupler]]s, the link-and-pin survived on [[forest railway]]s. While simple in principle, the system suffered from a lack of standardisation regarding size and height of the links, and the size and height of the pockets. |

|||

The link-and-pin coupler consisted of a tube-like body that received an oblong link. During coupling, a rail worker had to stand between the cars as they came together and guide the link into the coupler pocket. Once the cars were joined, the employee inserted a pin into a hole a few inches from the end of the tube to hold the link in place. This procedure was exceptionally dangerous and many brakemen lost fingers or entire hands when they did not get them out of the way of the coupler pockets in time. Many more were killed as a result of being crushed between cars or dragged under cars that were coupled too quickly. Brakemen were issued with heavy clubs that could be used to hold the link in position, but many brakemen would not use the club, and risked injury. |

|||

A peculiarly British institution was the "loose-coupled" freight train. This used three-link chain couplings with no means of drawing the wagons together: since such trains were not fitted with an automatic through-train braking system there were no pipes to connect between the vehicles. The couplings in the train were kept taut by the last vehicle of the train being a heavily ballasted [[guards van]] with its brakes set slightly on. This helped prevent snapped couplings. Such trains travelled at low speeds and were phased out in the 1970s. {{Fact|date=February 2008}} |

|||

The link-and-pin coupler proved unsatisfactory because: |

|||

An improvement on this is the "Instanter" coupling, in which the middle link of a three link chain is specially shaped so that when lying "prone" it provides enough slack to make coupling possible, but when this middle link is rotated 90 degrees the length of the chain is effectively shortened, reducing the amount of slack without the need to wind a screw. The closeness of the coupling allows the use of inter-vehicle pipes for train brakes. It also has the advantage that it can be operated entirely from the side of the wagons using a shunter's pole and is therefore safer when shunting work is under way. These couplings are still prevalent in UK freight trains today.{{Fact|date=February 2008}} |

|||

* It made a loose connection between the cars, with too much [[slack action]]. |

|||

* There was no standard design, and train crews often spent hours trying to match pins and links while coupling cars. |

|||

* Crew members had to go between moving cars during coupling, and were frequently injured and sometimes killed. |

|||

* The links and pins were often pilfered due to their value as scrap metal, resulting in substantial replacement costs. |

|||

* When a car happened to be turned 180 degrees one would have to look for a link. |

|||

* Railroads progressively began to operate trains that were heavier than the link-and-pin system could cope with. |

|||

In Britain link-and-pin couplers were common on narrow gauge industrial and military railways, and eventually evolved into a form that could be reliably coupled when the train was stationary. |

|||

=== Problems with buffers and chain === |

|||

The buffers and chain coupling system has a maximum load much less that the Janney coupling. Also, on sharp reverse curves, the buffers can get bufferlocked by somehow getting on the wrong side of the adjacent buffer. An accident at a Swiss station was caused by buffer-locked wagons in the 1980s.{{Fact|date=February 2008}} The bufferlock could be caused on the very sharp turnouts by the older rounded buffers. The newer buffers has rectangle shape and they are wider than taller. They are not so flat, so they rarely cause buffer locking.{{Fact|date=February 2008}} |

|||

The [[Panama Canal locks#Mules|Panama Canal mule]]s, the locomotives used to guide the ships through the locks of the [[Panama Canal]], have link and pin couplers and side buffers. This design was chosen so that these normally solo operating locomotives could be coupled to another locomotive in the event of a breakdown. On straight track, the link and pin coupler is used. Since the vertical curve between the straight track sections and the ramp between the lock chambers has a very small radius, the difference in height would be too great for a link and pin coupler, so the locomotives must be pushed through these sections uncoupled by using the side buffers. They have an extra high buffer plate to prevent the buffers from buffer-locking in tight vertical curves. |

|||

=== Variation with gauge === |

|||

[[Image:CH FO HGE44-105-2.JPG|thumb|The narrow gauge "buffer-&-chain" coupler, it's called ''Balancierhebelkupplung'']]The width between the buffers tends to increase as the gauge increases, so that if wagons are changed from one gauge to another, the buffers will no longer match. This occurs because the buffers are originally extensions of the frames, which are spaced according to the gauge. |

|||

{{clear}} |

|||

On some narrow-gauge lines in [[Europe]] a simplified version is used, consisting of a single central buffer with a chain underneath. It's called ''Balancierhebelkupplung''. The chain usually contains a screw-adjustable link to allow close coupling. On sharp curves, a single centre buffer is less likely to be subject to buffer locking problem, as described above. |

|||

== Balance lever coupling == |

|||

{{Main|Balance lever coupling}} |

|||

[[Image:VR Electric Locomotive Helsinki Finland.jpg|thumb|A Finnish locomotive with dual coupling]] |

|||

[[File:20060804S29 22Kupp.jpg|thumb|Balance lever coupling on narrow gauge coach in Switzerland]] |

|||

It is possible to mount both buffers and chain and knuckle couplers on the same car, provided that one can swing out of the way. |

|||

The balance lever coupling, also central buffer coupling with two screw coupling, is a coupler commonly used on narrow gauge railroads with tight curves. By swapping the pulling and pushing devices, the standard screw coupling used on standard gauge railroads became a center buffer coupling with one screw coupling on each side of the buffer. The screw couplers are connected to a compensating lever that pivots on a vertical trunnion on the center buffer rod, allowing an even distribution of tractive forces between the two screw couplers.<ref>Bruno Lämmli: [https://www.lokifahrer.ch/Lukmanier/Rollmaterial/Kupplung/Zug-Druck.htm ''Zug- / Stossvorrichtung.''] Auf: ''Lokifahrer,'' 2021.</ref> |

|||

==Albert coupler== |

|||

Locomotives and some freight cars of the Indian Railways are fitted with a 'transition coupler' that incorporates a screw coupling within a knuckle coupler: the knuckle coupler remains in position and does not swing away when not in use. The screw coupling is mounted on a lug within the knuckle coupler. See [http://www.ba-bautzen.de/wirtschaftssenioren/amk/amkenglish/wabconeu_e.htm SAB WABCO C-AK]. Most Indian freight cars use the knuckle coupler alone, without buffers, whereas passenger coaches almost exclusively use screw couplers and buffers. Exceptions are the new LHB coaches imported from Europe, and a few other makes of carriages converted to use knuckle couplers. [http://irfca.org/faq/faq-stock2.html] |

|||

[[File:Strassenbahn Albertkupplung.jpeg|thumb|Albert coupler on a European tram]] |

|||

To avoid safety issues, Karl Albert, then director at the [[Trams in Krefeld|Krefeld Tramway]], developed the '''Albert coupler''' during 1921. The Albert coupler was created as a key and slot coupler with two pins. Vehicles to be coupled were pushed together, both couplings moving to the same side. One pin was inserted, then the vehicles were pulled to straighten the coupling and the other pin inserted. This operation required less exact shunting. Due to the single-piece design, only minimal slack was possible. The system became quite popular with tram systems and narrow gauge lines. |

|||

During the 1960s most cities replaced them with automatic couplers. But even in modern vehicles, Albert couplers get installed as emergency couplers for towing a faulty vehicle. |

|||

[[Image:GNER-91116-coupling-01.jpg|thumb|British-style dual buffer-and-chain/automatic coupler with knuckle swung out of the way]]Some Russian locomotives and wagons have buffers together with the central coupler. When coupling to Finnish equipment, a short chain with a block that fits in the central coupler is placed on the Russian side, backing up and compressing the buffers so that the chain can be laid on the hook. (That is also the common way of coupling locomotives to or from wagons, faster than unscrewing the link.) |

|||

==Miller hook and platform== |

|||

British locomotive-hauled passenger carriages adopted a dual coupling system in the 1950s. They have retractable buffers and a central '''Buckeye''' automatic knuckle coupler that lowers to reveal a hook for a screw-type chain coupling. Inter-stock coupling was with the automatic coupler (with the buffers retracted), while connection to the locomotive was with the buffer-and-chain system with a screw coupler. |

|||

The link and pin was replaced in North American passenger car usage during the latter part of the 19th century by the assemblage known as the [[Miller platform]], which included a new coupler called the Miller hook.<ref>[https://3.bp.blogspot.com/-DfQAzcJxZd4/WeSz7ATgcRI/AAAAAAAAcXA/tlA82fwwJoQp_hxaQU7DjGp8iLcHfUhAQCLcBGAs/s1600/C17%2B534%2B%25281280x960%2529.jpg Miller Hook]</ref> The Miller platform (and hook coupler) was used for several decades before being replaced by the [[Janney coupler]]. |

|||

== |

==Norwegian== |

||

{{Main|Norwegian coupling}} |

|||

[[Image:Link and pin coupler pocket.jpg|thumb|The coupler pocket (just below the two lights) for a link and pin coupler on a 15 [[inch]] (381 [[millimetre|mm]]) [[rail gauge|gauge]] [[speeder]].]] |

|||

[[File:URCengines.jpg|right|thumb|Norwegian coupling in [[Uganda Railways Corporation|Uganda]]]] |

|||

The '''link and pin''' coupling was the original style of coupling used on American railways, surviving after conversion to Janney couplings on forestry railways. While simple in principle, the link and pin coupling suffered from a lack of standardisation regarding size and height of the links. |

|||

The Norwegian coupler consists of a central buffer with a movable hook that drops into a slot in the central buffer.<ref name="nw">{{cite web|url=http://members.ozemail.com.au/~telica/Norway_Setesdalsbanen.html|title=Setesdals Railway|website=Members.ozemail.com.au|access-date=2016-04-08|archive-date=2016-03-04|archive-url=https://web.archive.org/web/20160304072613/http://members.ozemail.com.au/~telica/Norway_Setesdalsbanen.html|url-status=dead}}</ref> There may also be a U-shaped safety catch on the opposite buffer that is flipped over the top of the hook to secure it. The safety device may also be a chain with a ball-shaped weight at the end that is thrown over the hook to hold it in place.<ref name="nw"/> On railways where the rolling stock always face the same direction, the mechanical hook can be on one end of the wagon only. Not all Norwegian couplers are compatible with one another as they vary in height and width, and may or may not be limited to one hook at a time. The traction force limit is typically 350 kN.<ref>{{cite web |title=Lloyd MCA-PH |url=https://laf-lloyd.com/en/lloyd-mca-ph/ |website=LAF}}</ref> Sometimes the Norwegian coupler is supplemented with auxiliary chains. |

|||

The link and pin coupler consisted of a tubelike body that received an oblong link. During coupling, a railworker had to stand between the cars as they came together and guide the link into the coupler pocket. Once the cars were joined, the employee inserted a pin into a hole a few inches from the end of the tube to hold the link in place. This procedure was exceptionally dangerous and many brakemen lost fingers or entire hands when they did not get their hands out of the way of the coupler pockets; many more were killed as a result of being crushed between cars or dragged under cars that were coupled too quickly. Brakemen were issued with heavy clubs that could be used to hold the link in position, but many brakemen would not use the club, and risk injury. |

|||

The Norwegian coupler is also known as the Lloyd coupler named after its British manufacturer F.H. Lloyd & Co. Ltd near [[Wednesbury]] or as the meat chopper coupler named after the shape of the movable hook. The Norwegian coupler allows sharper curves than the buffer and chain coupler, which is an advantage on [[narrow gauge railway]]s where low speeds and reduced train loads allow a simpler system. The Norwegian coupler is found only on [[narrow gauge railway]]s of {{RailGauge|1067mm|lk=on}}, {{RailGauge|1000mm|lk=on}} or less in [[Great Britain]] and its former colonies. For example, it is used on the [[Isle of Man Railway]], the [[Western Australian Government Railways]], in [[Tanzania]], on the [[Ffestiniog Railway]], on the [[Lynton and Barnstaple Railway]], and on the [[Welsh Highland Railway]], |

|||

The link and pin coupler proved unsatisfactory because: |

|||

{{Clear}} |

|||

* It made a loose connection between the cars, with too much [[slack action]]. |

|||

* There was no standard design, and train crews often spent hours trying to match pins and links while coupling cars. |

|||

* The links and pins were often pilfered (due to their value as scrap metal), resulting in substantial replacement costs. John H. White suggests that the railroads considered this to be more important than the safety issue at the time (see reference below). |

|||

* Crew members had to go between moving cars during coupling, and were frequently injured and sometimes killed. |

|||

* Eventually, railroads wished to operate trains that were heavier than the link and pin system could cope with. |

|||

==Radial couplers== |

|||

An episode of the 1960s TV series ''[[Casey Jones]]'' was devoted to the problems of link and pin couplings. |

|||

Two versions of radial coupler were used in South Africa. One, the Johnston coupler, commonly known as a bell link-and-pin coupler, was introduced in 1873 and is similar in operation to and compatible with [[#Link and pin|link-and-pin]] couplers, but bell-shaped with a circular coupler face. The other, the bell-and-hook coupler, was introduced in 1902 and is similar to the [[#Norwegian|Norwegian coupler]], but also with a circular coupler face and with a coupler pocket which is open at the top of the coupler face to accommodate the drawhook.<ref name="Trokhandboek">Suid-Afrikaanse Vervoerdienste (South African Transport Services) (1983). ''Passassierswa- en Trokhandboek (Passenger Carriage and Truck Manual), Vol 1, Hoofstukke 1-15 (Chapters 1-15)''. South African Transport Services, 1983. Chapter 13.</ref> |

|||

===Johnston coupler=== |

|||

==Norwegian== |

|||

[[File:Early Janney-type AAR coupler.JPG|thumb|Transition era AAR knuckle coupler. The gap in the knuckle accommodates the link of a [[#Johnston coupler|Johnston coupler]] and the vertical hole in the knuckle accommodates the pin.]] |

|||

[[Image:Alco.jpg|300px|right|thumb|Norwegian coupling fitted to an ex-[[War Department Light Railways|WDLR]] Alco at the [[Ffestiniog Railway]]]] |

|||

The Johnston coupler, commonly known as a bell link-and-pin coupler from its bell shape, was first introduced in the [[Cape Colony|Cape of Good Hope]] in 1873, following the establishment of the [[Cape Government Railways]] (CGR) in 1872 and the decision by the Cape government to expand the railways into the interior and to [[Track gauge conversion|convert]] the existing tracks from {{Track gauge|56.5in|allk=on}} to {{Track gauge|42in|lk=on}} Cape gauge. All new Cape gauge locomotives and rolling stock acquired from 1873 were equipped with these or similar couplers, beginning with the [[CGR 0-4-0ST 1873|CGR 0-4-0ST of 1873]], a construction locomotive named ''Little Bess''.<ref name="SAR History">{{cite book| title=The South African Railways - Historical Survey| editor=George Hart| publisher=Bill Hart, Sponsored by Dorbyl Ltd.| year=1978| pages=9, 11–13}}</ref><ref name="Holland 2">{{Holland-Vol 2|pages=51-52, 117-118}}</ref><ref name="Paxton-Bourne">{{Paxton-Bourne|pages=6, 110-112, 156-157}}</ref> |

|||

[[Image:URCengines.jpg|300px|right|thumb|Norwegian coupling from Uganda]] |

|||

[[File:Johnston link-and-pin coupler.jpg|thumb|left|Johnston link-and-pin coupler]] |

|||

'''Norwegian''' (or '''meat chopper''') couplings consist of a central buffer with a mechanical hook that drops into a slot in the central buffer. The Norwegian is found only on [[narrow gauge railway]]s {{Fact|date=December 2007}}, such as the [[Ffestiniog Railway]] and the [[Welsh Highland Railway]], where low speeds and reduced train loads allow a simpler system. On railway lines where rolling stock always points the same way, the mechanical hook may be provided only on one end of each wagon. This was the situation on the [[Lynton and Barnstaple Railway|Lynton & Barnstaple]] (L&B), a narrow gauge line in [[Devon]], [[England]], and still applies to railways in [[New Zealand]]. Similarly, the hand brake handles may also be on one side of the wagons only. |

|||

The [[Natal Government Railways]] (NGR), established in the [[Colony of Natal]] in 1875, followed suit and all locomotives and rolling stock acquired by that railway were equipped with Johnston couplers, beginning with the [[NGR Class K 2-6-0T]] in 1877.<ref name="Holland 1">{{Holland-Vol 1|pages=84-87, 109-112}}</ref><ref name="SAR&H May 1944">Espitalier, T.J.; Day, W.A.J. (1944). ''The Locomotive in South Africa - A Brief History of Railway Development. Chapter III - Natal Government Railways''. South African Railways and Harbours Magazine, May 1944. pp. 337-340.</ref> |

|||

Likewise, in 1889, when the first locomotives were obtained by the newly established [[Netherlands-South African Railway Company]] in the [[South African Republic|''Zuid-Afrikaansche Republiek'']], they were fitted with Johnston couplers.<ref name="Holland 2"/><ref name="SAR&H Oct 1944">Espitalier, T.J.; Day, W.A.J. (1944). ''The Locomotive in South Africa - A Brief History of Railway Development. Chapter IV - The N.Z.A.S.M.''. South African Railways and Harbours Magazine, October 1944. pp. 762, 764.</ref> |

|||

Norwegian couplings are not particularly strong, and may be supplemented by auxiliary chains. The L&B originally used side chains in conjunction with Norwegian couplers, but these were found to be unnecessary with the slow speeds employed (10-15 miles per hour) and were removed within a year or so of the line opening in 1898. |

|||

Unlike the {{Track gauge|24in|lk=on}} narrow gauge railways of the CGR, those of the NGR also made use of Johnston couplers. The first of these narrow gauge lines came into operation in 1906, when the first [[NGR Class N 4-6-2T 1906|NGR Class N 4-6-2T]] locomotives entered service on the [[Weenen]] branch out of [[Estcourt]].<ref name="Paxton-Bourne"/><ref name="SAR&H Sep 1944">Espitalier, T.J.; Day, W.A.J. (1944). ''The Locomotive in South Africa - A Brief History of Railway Development. Chapter III - Natal Government Railways'' (Continued). South African Railways and Harbours Magazine, September 1944. p. 669.</ref> |

|||

The [[Pichi Richi Railway]] in [[South Australia]] uses Norwegian couplers as its standard, and converts Janney coupler to Norwegian as required. The slot in the "buffer beam" where the coupler protrudes appears to be about the same for both types of couplers. As a museum, it is appropriate to use the older type of coupling. |

|||

Coupling and uncoupling were done manually, which posed a high risk of serious injury or death to crew members, who had to go between moving vehicles to guide the link into the coupler pocket during coupling. Johnston couplers gradually began to be replaced on the [[South African Railways]] from 1927, but not on narrow gauge rolling stock. All new Cape gauge locomotives and rolling stock acquired from that year were equipped with [[Janney coupler|AAR knuckle]] couplers. Conversion of all older rolling stock was to take several years and both coupler types could still be seen on some vehicles into the late 1950s. During the transition period, knuckle couplers on many locomotives had a horizontal gap and a vertical hole in the knuckle itself to accommodate, respectively, a link and a pin, to enable it to couple to vehicles which were still equipped with the older Johnston couplers.<ref name="Holland 2"/><ref name="Diagram-book 2">South African Railways & Harbours/Suid Afrikaanse Spoorweë en Hawens (15 Aug 1941). ''Locomotive Diagram Book/Lokomotiefdiagramboek, 2′0″ & 3′6″ Gauge/Spoorwydte, Steam Locomotives/Stoomlokomotiewe''. SAR/SAS Mechanical Department/Werktuigkundige Dept. Drawing Office/Tekenkantoor, Pretoria. pp. 6a-7a, 25.</ref> |

|||

===Bell-and-hook coupler=== |

|||

Not all Norwegian couplings are compatible with one another as they vary in height, width, and may or may not be limited to one hook at a time. |

|||

The bell-and-hook coupling system was first introduced in the Cape of Good Hope in 1902, when two [[CGR Type A 2-6-4T]] locomotives were acquired as construction engines on the new {{Track gauge|2ft|lk=on}} narrow gauge [[Avontuur Railway]] which was being constructed out of [[Port Elizabeth]] through the [[Langkloof]]. In South Africa, these couplers were used on only the narrow gauge lines in the Cape of Good Hope.<ref name="Trokhandboek"/><ref name="Paxton-Bourne"/><ref name="SAR&H Apr 1944">Espitalier, T.J.; Day, W.A.J. (1944). ''The Locomotive in South Africa - A Brief History of Railway Development. Chapter II - The Cape Government Railways'' (Continued). South African Railways and Harbours Magazine, April 1944. pp. 253-257.</ref><ref name="Dulez 150">{{Dulez 150|page=232}}</ref> |

|||

The coupler is similar to the [[Norwegian coupling|Norwegian coupler]]. It is a radial coupler with a coupler pocket which is open at the top of the coupling face. Instead of a link and pins, it makes use of a drawhook which, upon coupling, slides over the drawhook pin in the coupler of the next vehicle in the train. To prevent the drawhook of the mating coupler from accidental uncoupling, the coupler bell is equipped with a drawhook guard, commonly known as a bridle, above the coupler pocket.<ref name="Trokhandboek"/> |

|||

== Automatic couplers == |

|||

There are a number of automatic train couplings, most of which are mutually incompatible. |

|||

* '''AAR ([[American Association of Railroads]])''' coupler (also known as '''knuckle coupler''' and once known as '''Janney coupler''', '''alliance coupler''', see below) used in [[Rail transport in Canada|Canada]], the [[Rail transport in the United States|USA]], [[Mexico]], [[Rail transport in Japan|Japan]], [[Rail transport in Australia|Australia]], [[South Africa]], [[Saudi Arabia]], [[Cuba]], [[Chile]], [[Brazil]], [[Rail transport in the People's Republic of China|China]] and elsewhere. |

|||

** Maximum tonnage as high as 32,000 t. such as [[Fortescue Metals Group|Fortescue Railway]]. |

|||

** Drawbar pull tractive effort rated with a minimum strength 350000 lb. (approx. 159 t.) for general service coupler made of Grade B steel. Grade E knuckles may have an ultimate strength of 650,000 lb. (approx. 300 t.) |

|||

** The AAR (Janney) couplers comes in at least two sizes, "full size" and "three quarter", which are not compatible. Lighter weight railways, especially those of narrow gauge or with no need for interrunning sometimes use smaller (3/4 or half size) versions of the AAR coupling. |

|||

** AAR couplers are always right-handed. |

|||

** AAR are not necessarily mounted at the same height above rail - some variation can be tolerated. |

|||

** AAR couplers are uncoupled by lifting the coupling pin with a lever at the corner of the car. This pin is locked when the coupler is under tension, so the usual uncoupling steps are to compress the coupling with a locomotive, lift and hold up the pin, then pull the cars apart. Side operated variants are called the "'''Sharon coupler'''" or "'''Buckeye coupler'''" [http://www.wsr.org.uk/couplings.htm]. |

|||

** Trains fitted with AAR couplers can have heavier loads than any other type of coupler. Thus the heaviest coal trains in [[New Zealand]] have AAR couplings even though the remainder of the fleet has the '''meatchopper''' kind. Also, long-distance freight trains in [[North America]] are quite commonly more than a mile (1.6 km) long, whereas this is unknown in [[Europe]], where most freight trains still use the '''buffers and chain''' system. |

|||

** See also "'''Janney Coupler'''" and "'''changes since 1873'''" below. |

|||

* [[Russia]]n [[SA3 coupler]] , also known as a "[[Willison Coupler]] with a Russian contour", (somewhat similar to Janney) used in [[Russia]], former [[Soviet Union]], [[Finland]], [[Mongolia]], [[Iraq]] and on [[Malmbanan]], [[Sweden]]. See also: [http://railways.id.ru/glossary/avtoscepka.html Animation showing SA3 coupling] (site in Russian) |

|||

** Russian trains are rarely longer than about 750 m and rarely exceed a maximum tonnage about 6,000 t, so it is not clear what potential load these couplings are capable of. |

|||

** The effort to break the SA-3 coupler is about 300 t. |

|||

** Maximum allowed tractive effort to the SA-3 is limited to 135 t. by Russian white papers. |

|||

** [[Malmbana]] trains are about 8,000T. |

|||

* [http://www.ba-bautzen.de/wirtschaftssenioren/amk/amkenglish/wabconeu_e.htm European proposal coupler ], (compatible with the Russian coupler) with automatic air, control and power connections. Implementation permanently delayed except for a few users. |

|||

* '''Scharfenberg coupler''' used on electric passenger trains - connects brake and controls. See '''Fully Automatic Couplings''' below. |

|||

** Maximum tonnage under 1,000 t. |

|||

* Note: There are a number of other automatic train couplings similar to the Scharfenberg coupler, but not necessarely compatible with it. Older US transit operators continue to use these non-Janney electro-pneumatic coupler designs and have used them for decades. |

|||

Usual practice was to have a drawhook fitted to only one of the mating couplers and train crews therefore carried spare drawhooks and drawhook pins on the locomotive. While automatic coupling is possible, this rarely happens and manual assistance is required during coupling. Uncoupling is done manually by lifting the drawhook by hand to release it. The coupler could be adapted to be compatible with the Johnston coupler by replacing the drawhook with a U-shaped adapter link, which was attached using the same drawhook pin.<ref name="Trokhandboek"/> |

|||

=== Janney coupler === |

|||

Later '''[[Master Car Builders Association]] coupler''', now '''AAR ([[American Association of Railroads]]) coupler''', see also '''AAR coupler''' above. |

|||

[[Image:Railroad coupler diagram.jpg|thumb|250px|Diagram of the top view of Janney's coupler design as published in his patent application in [[1873]].]] Janney couplings are always right-handed. |

|||

Bell-and-hook couplers began to be replaced on the [[Avontuur Railway]] upon the introduction of [[South African Class 91-000|Class 91-000]] diesel-electric locomotives on the narrow gauge system in 1973. All new narrow gauge rolling stock acquired for that line from that year were equipped with [[SA3 coupler|Willison couplers]]. Older rolling stock were not converted and an adapter was used to enable coupling between the two types. The drawhook on the bell-and-hook coupler would be replaced with the adapter, which was attached using the same drawhook pin.<ref name="Trokhandboek"/> |

|||

The '''knuckle coupler''' or '''Janney coupler''' was invented by '''[[Eli H. Janney]]''', who received a [[patent]] in 1873 ({{US patent|138405}}). It is also known as a "buckeye coupler", notably in the [[United Kingdom]], where some rolling stock (mostly for passenger trains) is fitted with it. Janney was a dry goods clerk and former [[Confederate Army]] officer from [[Alexandria, Virginia]], who used his lunch hours to whittle from wood an alternative to the '''link and pin coupler'''. |

|||

<gallery mode="packed" neights="140px"> |

|||

File:Bell-and-hook coupler.jpg|left|Bell-and-hook coupler |

|||

File:Bell-and-hook coupler & Willison adapter.jpg|Bell-and-hook coupler with Willison adapter |

|||

File:Willison adapter b.jpg|left|Willison coupler adapter for bell-and-hook couplers |

|||

File:Bell-and-hook coupler & Johnston adapter.jpg|Bell-and-hook coupler with Johnston coupler adapter link instead of a hook |

|||

</gallery> |

|||

==Automatic couplers== |

|||

In 1893, satisfied that an automatic coupler could meet the demands of commercial railroad operations and, at the same time, be manipulated safely, the [[United States Congress]] passed the [[US Railroad Safety Appliance Act|Safety Appliance Act]]. Its success in promoting switchyard safety was stunning. Between 1877 and 1887, approximately 38% of all railworker accidents involved coupling. That percentage fell as the railroads began to replace link and pin couplers with automatic couplers. By 1902, only two years after the SAA's effective date, coupling accidents constituted only 4% of all employee accidents. Coupler-related accidents dropped from nearly 11,000 in 1892 to just over 2,000 in 1902, even though the number of railroad employees steadily increased during that decade. |

|||

There are a number of automatic train couplings, most of which are mutually incompatible. The level of automation varies and can be divided into categories: |

|||

* mechanical coupling of vehicles only, requires manual connection of pneumatic and electrical lines; |

|||

* mechanical coupling of vehicles with automatic connection of pneumatic lines, requires manual connection of electrical lines; |

|||

* mechanical coupling of vehicles with automatic connection of pneumatic and electrical lines (but not data transmission lines); |

|||

* mechanical coupling of vehicles with automatic connection of pneumatic and electrical lines (including data transmission lines); |

|||

* mechanical coupling of vehicles with automatic connection of pneumatic and electrical lines (including data transmission lines) and automatic uncoupling capability.{{sfn|DAC Report|2020|p=13}} |

|||

=== Buckeye/Janney/MCB/ARA/AAR/APTA couplers === |

|||

When the Janney coupling was chosen to be the American standard, there were 8000 patented alternatives to choose from. |

|||

{{Main|Janney coupler|Tightlock coupling}} |

|||

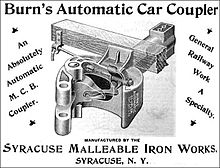

[[File:Syracuse-malleable 1899.jpg|left|thumb|[[Syracuse Malleable Iron Works]] – 1894. The gap in the knuckle accommodates the link of a [[Coupling (railway)#Link and pin|link and pin coupler]] and the vertical hole in the knuckle accommodates the pin. This design was used in the transition period.]] |

|||

[[File:Railroad coupler.agr2.jpg|thumb|right|Knuckle (AAR Type "E") couplers in use]] |

|||

[[File:Janney coupler drawing.png|thumb|right|Diagram of the top view of Janney's coupler design as published in his patent application in 1873]] |

|||

[[File:Northern-321901-coupling-02.jpg|left|thumb|[[American Public Transportation Association|APT]] [[Tightlock coupling|Type H Tightlock coupler]] on [[British Rail Class 321]].<br>Lower electric connector is not typical in North America.]] |

|||

The Janney coupler, later the Master Car Builders Association (MCB) coupler,<ref name=MCB>{{cite web|url=https://archive.org/search.php?query=creator%3A%22Master%20Car-Builders'%20Association%22 |title=Internet Archive Search: creator:"Master Car-Builders' Association" |website=Archive.org |access-date=2016-04-08}}</ref> now the [[Association of American Railroads]] (AAR) coupler, is also commonly known as a ''buckeye'', ''knuckle'', or ''Alliance'' coupler. The AAR/APTA TypeE, TypeF, and TypeH couplers are all compatible Janney couplers, but used for different rail cars (general freight, tank cars, rotary hoppers, passenger, etc.). |

|||

The knuckle coupler or Janney coupler was invented by [[Eli H. Janney]], who received a [[patent]] in 1873 ({{US patent|138405}}).<ref>{{cite web|url=http://inventors.about.com/library/inventors/bljannycoupler.htm|title=Eli Janney - The Janney Coupler|website=Inventors.about.com|access-date=2016-04-08|archive-date=2008-11-06|archive-url=http://webarchive.loc.gov/all/20081106171853/http://inventors.about.com/library/inventors/bljannycoupler.htm|url-status=dead}}</ref> It is also known as a ''buckeye coupler'', notably in the United Kingdom, where some rolling stock (mostly for passenger trains) is fitted with it. Janney was a dry goods clerk and former [[Confederate Army]] officer from [[Alexandria, Virginia]], who used his lunch hours to whittle from wood an alternative to the link and pin coupler. The term ''buckeye'' comes from the nickname of the US state of [[Ohio]], the "Buckeye State" and the Ohio Brass Company which originally marketed the coupling.<ref name="aec">{{cite web|url=http://www.aecinfo.com/1/company/09/17/09/company_1.html |title=Ohio Brass Co. Company Profile on |website=Aecinfo.com |access-date=2016-04-08}}</ref><ref name="brass">{{cite web|url=http://www.rootsweb.ancestry.com/~ohrichla/PofP/Leaf/OhioBrass.pdf |title=Ohio Brass Started As Small Jobbing Foundry In 1888 |website=Rootsweb.ancestry.com |access-date=2016-04-08}}</ref> |

|||

The only significant defect of the AAR (Janney) design is that sometimes the drawheads need to be manually aligned. |

|||

In 1893, satisfied that an automatic coupler could meet the demands of commercial railroad operations and, at the same time, be manipulated safely, the [[United States Congress]] passed the [[US Railroad Safety Appliance Act|Safety Appliance Act]]. Its success in promoting switchyard safety was stunning. Between 1877 and 1887, approximately 38% of all railworker accidents involved coupling. That percentage fell as the railroads began to replace link and pin couplers with automatic couplers. By 1902, only two years after the SAA's effective date, coupling accidents constituted only 4% of all employee accidents. Coupler-related accidents dropped from nearly 11,000 in 1892 to just over 2,000 in 1902, even though the number of railroad employees steadily increased during that decade. |

|||

=== Changes since 1873 ===<!-- This section is linked from [[Buckeye]] --> |

|||

[[Image:SMS 301-coupler.jpg|thumb|250px|Standard ARR Type E couplers doing their job on a freight train.]] |

|||

The AAR coupler has stood the test of time since its invention, and has seen only minor changes: |

|||

* It is clear that the original Janney coupler is no longer compatible with the latest AAR couplers. A visual comparison between the original Janney contour and the current AAR contour (see the illustration of the "'''Diagram of the top view of Janney's coupler...'''" and the photograph of the "'''Knuckle couplers in use'''" elsewhere in this article) would strongly indicate that the original Janney contour and the current AAR contour (especially that of the knuckle itself) are no longer compatible. The current AAR contour dates back to the "[[Master Car Builders Association]] (MCBA)" coupler. |

|||

* Buckeye coupler, a side operated version of the MCBA coupler [http://www.wsr.org.uk/couplings.htm] |

|||

* Type "E" coupler, the original (plain) AAR coupler, derived from the Master Car Builders Association coupler. |

|||

* Type "F" coupler, a "Tooth and socket" variation to prevent accidents, derailments and wrecks from uncoupling the couplers. The "tooth" on a loose coupler could puncture any [[tank car]] or other car carrying hazardous materials. Variations on the AAR type "F" coupler have been devised to provide extra protection, in case of derailments and train wrecks, to cars routinely carrying sensitive or hazardous loads. These variations of type "F" couplers, generally involving "shelves", remain fully compatible with standard AAR couplers, but tend to keep derailments and collisions from uncoupling the cars (thereby preventing the "tooth" of the couplers from piercing the ends of the cars). |

|||

* The APTA (former AAR) standard type "H" coupler, a "Tooth and socket" variation used mostly, if not exclusively, on passenger cars. Types "F" and "H" couplers are also known as [[tightlock coupling]]s. The Type "H" coupler is now under the supervision of the APTA ([[American Public Transportation Association]]) |

|||

* "pads" to reduce slack on passenger trains. |

|||

* improvement to castings, etc. to increase maximum trailing load. |

|||

* rotating-shaft couplers (type "F") introduced for use in [[rotary car dumper]]s such as on the [[Pilbara]] railways. |

|||

* narrow gauge railways such as the [[Victoria (Australia)|Victorian]] [[Puffing Billy Railway]] use a miniature version of the AAR coupler. |

|||

When the Janney coupler was chosen to be the North American standard, there were 8,000 patented alternatives to choose from. Many AAR coupler designs exist to accommodate requirements of various car designs, but all are required to have certain dimensions in common which allow for one design to couple to any other.<ref name="AAR MRSP:SIII">AAR Manual of Standards and Recommended Practices, Section S, Part III:Coupler and Yoke Details, Issue 06/2007</ref> |

|||

== Fully automatic couplings == |

|||

Fully automatic couplings are those that make all connections between the rail vehicles (mechanical, air brake and electrical) without human intervention, in contrast to autocouplers which just handle the mechanical aspects. The majority of trains fitted with these types of couplers are multiple units, especially those used in [[mass transit]] operations. |

|||

The Janney coupler is used in the [[Rail transport in the United States|United States]], [[Rail transport in Canada|Canada]], [[Rail transport in Mexico|Mexico]], [[Rail transport in Japan|Japan]], [[Rail transport in India|India]], [[Rail transport in Taiwan|Taiwan]], [[Rail transport in Australia|Australia]], [[Rail transport in New Zealand|New Zealand]], [[Rail transport in South Africa|South Africa]], [[Rail transport in Saudi Arabia|Saudi Arabia]], [[Rail transport in Cuba|Cuba]], [[Rail transport in Chile|Chile]], [[Rail transport in Brazil|Brazil]], [[Rail transport in Portugal|Portugal]], [[Rail transport in the People's Republic of China|China]] and many countries in Africa both standard gauge and narrow gauges. |

|||

There are a few designs of fully automatic couplers in use worldwide, including the Scharfenberg coupler, various knuckle hybrids (such as the Tightlock, used in the UK), the wedgelock coupling, Dellner couplings (similar to Scharfenberg couplers in appearance), and the BSI coupling. |

|||

The Janney coupler generally provides only mechanical coupling, only Type H adds automatic connections of pneumatic and electrical lines.{{sfn|DAC Report|2020|p=30–31}} |

|||

Older US transit operators use non-Janney electro-pneumatic coupler designs that have been in service for decades. |

|||

{{clear}} |

|||

====Changes since 1873==== |

|||

{{Main|Janney coupler#Changes since 1873|l1=Janney coupler § Changes since 1873}} |

|||

====Bazeley coupler==== |

|||

<gallery> |

|||

{{Main|Janney coupler#Bazeley Coupler|l1=Janney coupler § Bazeley coupler}} |

|||

Image:Northern-333011-coupling.jpg|Dellner manufactured Scharfenberg |

|||

Image:ICE3_Scharfenberg_coupling_detail_view.jpg|Scharfenberg |

|||

====Henricot coupler==== |

|||

Image:Northern-144023-coupling-01.jpg|BSI |

|||

{{Main|Janney coupler#Henricot coupler|l1=Janney coupler § Henricot coupler}} |

|||

Image:Northern-321901-coupling-02.jpg|APTA, Type "H", [[Tightlock coupling]] |

|||

Image:London Underground 1996ts.jpg|Wedgelock |

|||

The Henricot coupler is a variation on the Janney coupler, introduced by Belgian engineer and entrepreneur {{ill|Émile Henricot|fr|Émile Henricot}} of [[Court-Saint-Étienne]]. It is used on certain EMUs of the [[National Railway Company of Belgium]], including the {{ill|Belgian Railways Class 75|lt=Class 75|fr|Automotrice AM75}}). |

|||

Image:SEPTA_budd-coupler.jpg|[[Budd Company|Budd]] Pin and cup coupler |

|||

{{-}} |

|||

<gallery mode="packed" heights="150px" caption="Henricot couplers"> |

|||

Image:AM75 Série 800 SNCB.jpg|Henricot coupler on an [[NMBS/SNCB class 75|SNCB Class 75]] EMU with separate [[Railway air brake|air brake]] and [[head-end power]] connections |

|||

File:Attelage Henricot.jpg|Henricot coupler on a [[Belgian Railways Classical twin EMUs|Belgian EMU]] |

|||

File:NMBS 837.JPG|Closeup of Henricot coupler |

|||

</gallery> |

</gallery> |

||

===Willison/SA3 coupler=== |

|||

{{Main|SA3 coupler}} |

|||

[[File:Scepka.GIF|thumb|right|The simplified scheme of the SA-3 automatic couplers.<br>[[:File:Sa3.gif|An animation of the SA-3 coupler]]]] |

|||

[[File:Class 91-000 no. 91-004 Willison coupler.jpg|thumb|Willison coupler on South African {{Track gauge|2ft|lk=on}} narrow gauge]] |

|||

The Willison coupler was developed in the US in 1916 to address issues present in the Janney coupling.{{sfn|DAC Report|2020|p=19}} |

|||

The Russian SA3 coupler works according to the same principles as the AAR coupler but the two types are incompatible.<ref>{{cite web |url=http://railways.id.ru/glossary/avtoscepka.html |title=ДЖД - Толковый словарь |website=Railways.id.ru |date=2005-05-16 |access-date=2016-04-08 |archive-date=2014-04-26 |archive-url=https://web.archive.org/web/20140426201414/http://railways.id.ru/glossary/avtoscepka.html |url-status=dead }}</ref> It was introduced in the Soviet Union in 1932 based on a British patent and has since been used on the whole {{Track gauge|1520mm|lk=on}} network, including [[Rail transport in Mongolia|Mongolia]]. [[Rail transport in Finland|Finnish]] locomotives have Unilink couplers that can couple to UIC couplers used in Finnish stock and SA3 couplers used in Russian stock. |

|||

It is also used on the {{Track gauge|sg|allk=on}} networks of [[Rail transport in Iran|Iran]] and on [[Malmbanan]] in Sweden for ore trains. Some {{Track gauge|2ft|lk=on}} gauge cane tramway vehicles in [[Rail transport in Queensland|Queensland]] have been fitted with miniature Willison couplers.<ref>[[Light Railways]], October 2013, p. 23</ref> It was introduced on the {{Track gauge|2ft}} narrow gauge [[Avontuur Railway]] of the South African Railways in 1973.<ref name="Trokhandboek"/> |

|||

* Russian trains are rarely longer than about {{convert|750|m|0|abbr=on}}{{Citation needed|date=January 2011}} and rarely exceed a maximum tonnage of about {{convert|6000|t|abbr=on|lk=on}}{{Citation needed|date=January 2011}}. The heaviest trains using these couplers are on [[Malmbanan]] where they are up to {{convert|9000|t|abbr=on}}.<ref>{{Cite web |url=http://m.railjournal.com/index.php/freight/sweden-introduces-325-tonne-axleloads-on-iron-ore-line.html |title=Sweden introduces 32.5-tonne axleloads on Iron Ore Line |access-date=2017-10-29 |archive-date=2017-10-29 |archive-url=https://web.archive.org/web/20171029173006/http://m.railjournal.com/index.php/freight/sweden-introduces-325-tonne-axleloads-on-iron-ore-line.html |url-status=dead }}</ref> |

|||

* Maximum force the SA3 coupler is able to carry, both tensile and compressive, is about {{cvt|2.5|MN|STf LTf}}.{{sfn|DAC Report|2020|p=22}} |

|||

* The maximum allowed tractive effort to the SA-3 is limited to {{convert|135|tf|abbr=on}} ({{convert|1.32|MN|lbf|abbr=on|disp=or}}) by Russian white papers.{{Citation needed|date=January 2011}} |

|||

* The proposed European automatic coupler is compatible with the Russian coupler but with automatic air, control and power connections.<ref>{{cite web|url=http://www.ba-bautzen.de/wirtschaftssenioren/amk/amkenglish/wabconeu_e.htm |title=The SAB WABCO C-AK for goods wagons |access-date=October 15, 2009 |url-status=dead |archive-url=https://web.archive.org/web/20090519233410/http://www.ba-bautzen.de/wirtschaftssenioren/amk/amkenglish/wabconeu_e.htm |archive-date=May 19, 2009 }}</ref> Implementation is permanently delayed except for a few users. See [[#Unicoupler/Intermat|Europe]] below. |

|||

* The SA3 resembles a left-handed fist. |

|||

The SA3 coupler is one of the strongest couplers in the world – maximum tonnage of a train that uses this type of coupler is about 8000 t{{sfn|State of the Art on Automatic Couplers|2017|p=18}} – but provides only mechanical coupling.{{sfn|DAC Report|2020|p=30–31}} Adding automatic electrical and pneumatic connectivity is a complex challenge.{{sfn|DAC Report|2020|p=20}} |

|||

There are many variations and brand names for these couplers. |

|||

{{As of|2020}} [[Construcciones y Auxiliar de Ferrocarriles|CAF]] is working on an automatic coupler based on SA3, a possible replacement of the buffers and chain coupling on European railways.{{sfn|DAC Report|2020|p=5}} |

|||

====Unicoupler/Intermat==== |

|||

[[File:Ak.03 »Intermat« und »Unicupler«, von oben.jpg|thumb|right|Intermat and Unicoupler heads from above]] |

|||

Unicoupler has been developed by [[Knorr-Bremse|Knorr]] from West Germany in the 1970s, in parallel with a compatible counterpart, the Intermat coupler, by VEB Waggonbau Bautzen from East Germany.<ref>{{cite web|url=http://www.ba-bautzen.de/wirtschaftssenioren/amk/amkenglish/index.html |title=The Automatic Center Coupler for European Railways |access-date=November 16, 2010 |url-status=dead |archive-url=https://web.archive.org/web/20110718201619/http://www.ba-bautzen.de/wirtschaftssenioren/amk/amkenglish/index.html |archive-date=July 18, 2011 }}</ref><ref>{{cite web|url=http://www.ba-bautzen.de/wirtschaftssenioren/amk/amkenglish/geschichteamk_e.htm |title=History of the European Automatic Centre Coupler for Goods Wagons |access-date=August 3, 2008 |url-status=dead |archive-url=https://web.archive.org/web/20071030064842/http://www.ba-bautzen.de/wirtschaftssenioren/amk/amkenglish/geschichteamk_e.htm |archive-date=October 30, 2007 }}</ref> The Unicoupler/Intermat coupler can automatically couple two pneumatic lines and up to six electrical connections.{{sfn|DAC Report|2020|p=19}} |

|||

This coupler is mechanically compatible with [[SA3 coupler|SA-3]] and [[Willison coupler]]s (but pneumatic and electrical connections must be done manually). The Unicoupler is also known as AK69e. |

|||

Maximum tonnage of a train that uses this type of coupler is about 6000 t.{{sfn|State of the Art on Automatic Couplers|2017|p=18}} AK69e and Intermat adoption failure has been attributed to economic performance.{{sfn|State of the Art on Automatic Couplers|2017|p=19}} |

|||

{{As of|2020}} it has found limited use, it's been adopted by the [[Islamic Republic of Iran Railways|Iranian Railways]]{{sfn|DAC Report|2020|p=9}} and is also used in Germany on trains transporting iron ore between Hamburg and Salzgitter.{{sfn|DAC Report|2020|p=11}} |

|||

====C-AKv==== |

|||

{{Main|C-AKv coupler}} |

|||

The C-AKv coupler (also called Transpact) is a newer compact Willison coupler developed by [[Faiveley Transport]].<ref>{{cite web|url=http://www.faiveleytransport.com/ |title=Faiveley Transport Group - Systems and services for the railway industry |website=Faiveleytransport.com |access-date=2016-04-08}}</ref> It is mechanically compatible with the [[SA3 coupler]] (but pneumatic and electrical connections must be done manually), fully compatible with the Unicoupler and, if additional buffers are mounted, it can be coupled with the conventional European screw coupling as well.{{sfn|State of the Art on Automatic Couplers|2017|p=26}} The C-AKv coupler can automatically couple two pneumatic lines.{{sfn|State of the Art on Automatic Couplers|2017|p=19}} {{As of|2020}} its use is limited to trains transporting ore between Rotterdam and [[Dillinger Hütte|Dillingen steelworks]] and lignite between Wählitz and Buna in Germany.{{sfn|DAC Report|2020|p=11}} |

|||

====Z-AK==== |

|||

The Z-AK coupler is yet another Willison coupler developed by [[Knorr Bremse]]. It was designed in response to the obvious failure of the Unicoupler/Intermat. It is compatible with the buffers and screw coupling. It is one of only few automatic couplers that cannot carry tensile forces, railway vehicles using this type of coupler must be equipped with buffers as well.{{sfn|State of the Art on Automatic Couplers|2017|pp=19–20}} |

|||

====Unilink coupler==== |

|||

The Unilink coupler is a coupler, which is used in [[Commonwealth of Independent States|CSI]] border countries such as [[Rail transport in Finland|Finland]] or [[Rail transport in Ukraine|Ukraine]].<ref>{{cite book |title=Analysis of the basic parameters for maintaining the technical and operational compatibility of the 1520 mm and 1435 mm gauge rail systems at the Commonwealth of Independent States (CIS)/European Union (EU) border. Rolling stock. Passenger carrriages. |date=2013 |publisher=OSJD-ERA Contact Group |url=https://www.era.europa.eu/system/files/2022-11/Analysis%201520%20RST.%20Passenger%20Carriages%20%28EN%29.pdf |access-date=2023-12-16}}</ref> The coupler is compatible with both [[SA3 coupler|SA3]] and [[Buffers and chain coupler|screw coupling]].<ref>{{cite web |url=https://www.laf-lloyd.com/en/our-products/automatic-couplers |title=All purpose couplers: "Willison" type couplers |website=LAF |access-date=2021-02-17 |archive-date=2021-05-07 |archive-url=https://web.archive.org/web/20210507074829/https://www.laf-lloyd.com/en/our-products/automatic-couplers/ |url-status=dead }}</ref> It is an SA3 coupler with an additional horn that allows to attach the shackle of the screw coupler and with a screw coupler that is connected to the hook of wagons equipped with screw couplers. When the screw coupler is not in use, the coupler shakle rests in a holder on the left side of the coupler. Rolling stock equipped with Unilink couplers is also equipped with [[Buffer (rail transport)|side buffers]], which are required when using the screw coupler.{{sfn|DAC Report|2020|p=10}} |

|||

Finland uses passenger coaches equipped with screw couplers because they have the advantage over the SA3 coupler of providing a slack-free ride, as the screw couplers are always under tension and the side buffers do not separate in normal operation. Most Finish freight cars are also equipped with screw couplers. Only some heavy freight cars and Russian equipment are fitted with SA3 couplers. |

|||

=== Automatic Buffing Contact Coupler (ABC Coupler)<span class="anchor" id="Automatic Buffing Contact Coupler"></span> === |

|||

[[File:ABC coupler on a Kalka-Shimla train, 2011-12-26.JPG|thumb|ABC coupler on a [[Kalka Shimla Railway|Kalka–Shimla train]]]] |

|||

The Automatic Buffing Contact Coupler, better known as the ABC coupler, was invented by J.T. Jepson, patented in Great Britain in 1906<ref>{{cite patent |country=GB |number=190525511A |inventor=J.T. Jepson |status=patent |title=Improvements in connection with Automatic Couplings for Railway Vehicles and the like |pubdate=1906-08-16 |gdate= |fdate= |pridate= |assign1= |assign2= |url=}}</ref> and manufactured by the A.B.C. Coupler and Engineering Company Limited in a factory in [[Wolverhampton]]. |

|||

The coupling consists of a shackle that protrudes from a central buffer and falls into a hook in the opposite buffer when coupling contact is made. The non-engaged shackle of the opposite coupler rests on the engaged shackle, securing it against disengagement by its weight. To uncouple the ABC coupling, the upper shackle that is not engaged is lifted. This causes the tail lever attached to the shackle to lift the engaged shackle clear of the hook and release the coupling. |

|||

In 1912, an improved version of the coupling with a better locking mechanism was introduced, in which a spring-loaded locking bar blocked a disk serving as the hook. This disc hook was rotated into the locked position by the approaching shackle of the opposite coupling. To release the coupling, it was sufficient to release the locking bar by pulling on a chain or a handle, which released the rotation of the disk hook. |

|||

The coupler was mainly used on narrow gauge railways of the British colonies, like e.g. the [[Bauchi Light Railway]] in [[Nigeria]], [[Rail transport in Sri Lanka|Ceylon]], [[Rail transport in Honduras|Honduras]] or the [[Kalka-Shimla Railway]] in [[India]].<ref name=ABC>{{cite web|url=http://www.localhistory.scit.wlv.ac.uk/Museum/Transport/Trains/ABC/ABC01.htm |title=ABC Couplers |access-date=October 4, 2008 |url-status=dead |archive-url=https://web.archive.org/web/20090521124013/http://www.localhistory.scit.wlv.ac.uk/Museum/Transport/Trains/ABC/ABC01.htm |archive-date=May 21, 2009}}{{dead|date=September 2022}}</ref><ref>[http://www.historywebsite.co.uk/articles/FHL/ABC/ABC01.htm ABC]</ref> |

|||

===Stearns and Ward coupler=== |

|||

[[File:Stearns and Ward coupler.jpg|thumb|Stearns and Wards coupler on a car of the [[Northwestern Elevated Railroad]]]] |

|||

The Stearns and Ward coupler, known as the Ward coupler in the [[United Kingdom]], is named after its two American inventors, Robert B. Stearns and Frank D. Ward, who were jointly granted the patent {{patent|US|737673|"Car-coupling."}} in 1903. The coupler was specifically designed for use on [[elevated railway]]s<ref name="Ward"/> as they were introduced in [[Chicago]] at the turn of the century. It was first used on the electric trains of the [[Northwestern Elevated Railroad]] in 1902. Three years later in 1905 it was introduced by Wards in the electrification of the [[Circle line (London Underground)|Circle Line]] of the [[District Railway]], which became the [[London Underground]]. The Ward coupler was the standard coupler on London Underground trains until 1936, when it was replaced by the Wedglock coupler, a multi-function coupler that also provided pneumatic and electrical connections.<ref>{{cite web|url=http://www.trainweb.org/tubeprune/coupling.htm |title=Coupling, Handing and UNDMs |website=Trainweb.org |date=2002-08-24 |access-date=2016-04-08}}</ref> |

|||

The cars must be pushed together to couple. The tongue of each coupler head enters the throat of the opposite coupler head, where the hook on the tongue turns a vertically mounted, spring-loaded coupling pin against the force of the spring. Once the hook passes the coupling pin, the spring force returns the coupling pin to its original position, holding the hook head in the coupling. When coupled, the coupler heads are free to move vertically, which should prevent a derailed car from dragging other cars with it in the event of a derailment on the elevated railway. Uncoupling is done by turning the coupling pin against the spring force with an actuating arm operated by a shunting pole or by a fixed rod with handles that can be reached from a position next to the train away from the [[third rail]].<ref name="Ward">{{cite patent |country=US |number=737673 |invent1=Robert B. Stearns |invent2=Frank D. Ward |status=patent |title=Car-coupling |pubdate=1903-09-01}}</ref> |

|||

==Multi-function couplers== |

|||

Multi-function couplers (MFCs), or fully automatic couplers, make all connections between the rail vehicles (mechanical, air brake, and electrical) without human intervention, in contrast to autocouplers, or semi-automatic couplers, which just handle the mechanical aspects. The majority of trains fitted with these types of couplers are multiple units, especially those used in [[mass transit]] operations. |

|||

There are a few designs of fully automatic couplers in use worldwide, including the [[Scharfenberg coupler]], various knuckle hybrids such as the Tightlock (used in the UK), the Wedglock coupling, [[Dellner coupling]]s (similar to Scharfenberg couplers in appearance), BSI coupling (Bergische Stahl Industrie, now [[Faiveley Transport]]) and the Schaku-Tomlinson Tightlock coupling. |

|||

There are a number of other automatic train couplings similar to the Scharfenberg coupler, but not necessarily compatible with it. Older US transit operators continue to use these non-Janney electro-pneumatic coupler designs and have used them for decades. |

|||

===Westinghouse H2C=== |

|||

The [[Westinghouse Air Brake Company|Westinghouse]] H2C coupler, whose predecessor the H2A was first used on the [[BMT Standard]]s and later the [[R1 (New York City Subway car)|R1]] through [[R9 (New York City Subway car)|R9]] classes, is currently used on the [[R32 (New York City Subway car)|R32]], [[R42 (New York City Subway car)|R42]], [[R62 (New York City Subway car)|R62]], [[R62A (New York City Subway car)|R62A]], [[R68 (New York City Subway car)|R68]], and [[R68A (New York City Subway car)|R68A]] class subway cars of the [[New York City Subway]]. The A ends of the cars typically have the Westinghouse coupler and the B ends use either a semi-permanent [[Drawbar (haulage)#Rail|drawbar]], or a Westinghouse coupler. |

|||

===WABCO N-Type=== |

|||

[[File:SEPTA budd-coupler.jpg|thumb|left|[[Westinghouse Air Brake Company|WABCO]] Model N-2 on a [[SEPTA]] [[Budd Silverliner|Silverliner II]]]] |

|||

The WABCO N-Type coupler was first developed for the prototype [[Pittsburgh]] [[Transit Expressway Revenue Line|Skybus]] system with the initial model N-1 as applied only to the three Skybus cars. The updated model N-2 with a larger {{convert|4|in|1|adj=on}} gathering range was first applied to the new "Airporter" rapid transit cars on the [[Red Line (Cleveland)|Cleveland Rapid Transit]] line. The model N-2 used lightweight draft gear slung below the center sill, to allow for the wide swings required to go around sharp curves. This made the N-2 unsuitable for main line railroad use so an updated version N-2-A was developed for that market. The first of these were fitted in 1968 to the [[UAC TurboTrain]] with 228 electrical contacts and the [[M1 (railcar)|Budd Metropolitan EMU]] with 138 contacts. Starting in the 1970s the N-2-A was fitted to the entire [[SEPTA]] [[Silverliner]] family of MU's, the [[NJ Transit Rail Operations|NJT]] [[Arrow (railcar)|Arrow]] series of MU's and the [[Metro-North Railroad]]/[[Long Island Rail Road]] M series of MU railcars. The N-2 was also used by the [[PATCO Speedline]], but was replaced due to issues with the electrical contacts. Later WABCO would create a new model N-3 for the [[Bay Area Rapid Transit|BART]] system with a {{convert|6|×|4|in|1|adj=on}} gathering range which required a rectangular funnel. |

|||

The WABCO N-type is sometimes referred to as the '''pin and cup coupler''' or '''spear coupler'''. |

|||

{{clear}} |

|||

=== Tomlinson === |

|||

[[File:NYCS H46-6006-Mott-Ave-coupler.jpg|thumb|right|Tomlinson coupler as applied to a New York City Subway [[R46 (New York City Subway car)|R46]]]] |

|||

[[File:TRT-301-Tomlinson-Coupler-01.jpg|thumb|left|Tomlinson coupler as used on Eidan Subway (now Tokyo Metro) 300 series]] |

|||

The Tomlinson coupler was developed by the [[Ohio Brass Company]]<ref name="aec"/><ref name="brass"/> for mass transit applications, but eventually found use in some mainline railroad vehicles as well. It consists of two squared metal hooks that engage with each other in a larger rectangular frame with air line connections above and below. Since the coupler's development the manufacturing arm of Ohio Brass was purchased by WABCO which now manufacturers the line along with the N-type. The Tomlinson coupler is the most widely used fully automatic heavy rail coupling in North America having been adopted by the [[Washington Metro]], [[Massachusetts Bay Transportation Authority]], [[PATCO Speedline]], SEPTA [[Broad Street Line|Broad Street Subway]], [[Los Angeles Metro Rail]], [[Baltimore Metro SubwayLink|Baltimore Metro]], [[Metrorail (Miami-Dade County)|Miami Metro]], [[Metropolitan Atlanta Rapid Transit Authority|MARTA Rail]] and the [[New York City Subway]] for its [[R44 (New York City Subway car)|R44]]/[[R46 (New York City Subway car)|R46]] fleet and all modern classes starting with the [[R142 (New York City Subway car)|R142]]. For applications outside of rapid transit the coupler had to be significantly enlarged to meet the increased strength requirements first appearing in this capacity on the [[Budd Metroliner]] and later on the [[Illinois Central]] [[Highliner]] fleet. Its relative lack of strength is one reason the [[WABCO N-Type|N-Type]] has been more successful in the mainline railroad arena. |

|||

Outside the United States, the Tomlinson coupler is used on [[Tokyo Metro]]'s [[Ginza Line|Ginza]] and [[Marunouchi Line]]s<ref>{{cite web|url=http://www.sumidacrossing.org/Prototype/Couplers/|title=Prototype Couplers|website=Sumida Crossing}}</ref> and on the heavy capacity [[Taipei Metro]] lines.<ref>{{cite web|url=https://www.xuehua.tw/2018/08/17/%E8%87%BA%E5%8C%97%E6%8D%B7%E9%81%8Bc381%E5%9E%8B%E9%AB%98%E9%81%8B%E9%87%8F%E9%9B%BB%E8%81%AF%E8%BB%8A/|title=臺北捷運C381型高運量電聯車|author=OTIS Wang|website=雪花台灣}}</ref> |

|||

{{Clear}} |

|||

=== Scharfenberg coupler === |

=== Scharfenberg coupler === |

||

{{Main|Scharfenberg coupler}} |

|||

[[Image:100 6932.jpg|thumb|The [[DSB class MY| MY]] locomotive, normally screw-coupled, has got a '''Scharfenberg''' coupler mounted for transporting [[Alstom LHB Coradia LINT| Lint 41]] DMU's]] |

|||

[[ |

[[File:ICECoupler.jpg|thumb|right|[[Scharfenberg coupler]]]] |

||

[[File:Northern-333011-coupling.jpg|thumb|left|Scharfenberg coupler<br>made by [[Dellner]]]] |

|||

[[Image:Kuppelvorgang.jpg|thumb|Two ICE-T trains coupling. In picture #1 both trains are ready to be coupled, picture #2 shows the trains joined mechanically, picture #3 shows the trains coupled mechanically and electrically.]] |

|||

The Scharfenberg coupler<ref>{{cite web|url=http://www.voithturbo.de/scharfenberg.htm |title=Voith |website=Voithturbo.de |access-date=2016-04-08}}</ref> ({{lang-de|Scharfenbergkupplung}} or {{lang|de|Schaku}}) is probably the most commonly used type of fully automatic coupling. Designed in 1903 by Karl Scharfenberg in Königsberg, Germany (today [[Kaliningrad|Kaliningrad, Russia]]), it has gradually spread from transit trains to regular passenger service trains, although outside Europe its use is generally restricted to mass transit systems. The Schaku coupler is superior in many ways to many other automatic couplers because it makes the pneumatic and electrical connections automatically and is capable of automatic uncoupling.{{sfn|DAC Report|2020|pp=26, 30–31}} However, there is no standard for the placement of these electro-pneumatic connections. Some rail companies have them placed on the sides while others have them placed above the mechanical portion of the Schaku coupler. |

|||

Small air cylinders, acting on the rotating heads of the coupler, ensure the Schaku coupler engagement, making it unnecessary to use shock to get a good coupling. Joining portions of a passenger train can be done at very low speed (less than {{convert|2|mph|abbr=on|disp=or}} in the final approach), so that the passengers are not jostled about. Rail equipment manufacturers such as [[Bombardier Transportation|Bombardier]] offer the Schaku coupler as an option on their mass transit systems and their passenger cars and locomotives. In North America all the trains of the [[Montreal Metro]] are equipped with it, as are new light rail systems in [[RTD Bus & Rail|Denver]], [[Baltimore Light RailLink|Baltimore]] and [[NJ Transit|New Jersey]]. It is also used on [[light rail]] vehicles in [[TriMet|Portland]], [[Metro (Minnesota)|Minneapolis]], the [[SkyTrain (Vancouver)|Vancouver Skytrain]], and [[Line 3 Scarborough]] in [[Toronto]]. In New Zealand, it is found on the electric [[New_Zealand_AM_class_electric_multiple_unit|AM class]] of [[Auckland]]'s suburban rail network, and on the [[New_Zealand_FP_class_electric_multiple_unit|Matangi]] trains of [[Wellington]]'s. It also equips all the dedicated rolling stock used for the shuttle services in the [[Channel Tunnel]]. |

|||

The Scharfenberg coupler ({{lang-de|Scharfenbergkupplung ''or'' Schaku}}) is probably the most commonly used type of fully automatic coupling. Designed in 1903 by Karl Scharfenberg in Königsberg, Germany (today [[Kaliningrad|Kaliningrad, Russia]]), it has gradually spread from transit trains to regular passenger service trains, although outside Europe its use is generally restricted to mass transit systems. The Schaku coupler is superior in many ways to the AAR (Janney/Knuckle) coupler because it makes the electrical and also the pneumatic connections and disconnections automatic. However there is no standard for the placement of these electro-pneumatic connections. Some rail companies have them placed on the sides while others have them placed above the mechanical portion of the Schaku coupler. The main disadvantage to the Scharfenberg coupler is its low maximum tonnage, which makes it highly unsuitable for freight operations. |

|||

Maximum tonnage under {{convert|1000|t|ST LT|abbr=on}}. |

|||

Small air cylinders, acting on the rotating heads of the coupler, ensure the Schaku coupler engagement, making it unnecessary to use shock to get a good coupling. Joining portions of a passenger train can be done at very low speed (less than 2 [[Miles per hour|mph]]/3.2 [[Kilometres per hour|km/h]] in the final approach), so that the passengers are not jostled about. Rail equipment manufacturers such as [[Bombardier]] offer the Schaku coupler as an option on their mass transit systems and their passenger cars and locomotives. In [[North America]] all the trains of the [[Montreal Metro]] are equipped with it, as are new light rail systems in [[TheRide|Denver]], [[Baltimore Light Rail|Baltimore]] and [[New Jersey Transit|New Jersey]]. It is also used on [[light rail]] vehicles in [[TMTC|Portland]], [[Hiawatha Line|Minneapolis]], the [[SkyTrain (Vancouver)|Vancouver Skytrain]], and the [[Scarborough RT (TTC)|Scarborough RT]] in [[Toronto]]. |

|||

{{As of|2020}} [[Voith]] and [[Dellner]] are working on an automatic coupler based on Schaku, a possible replacement of the buffers and chain coupling on European railways.{{sfn|DAC Report|2020|pp=5, 23}} |

|||