Spacer fabrics

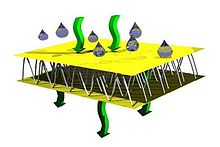

Knitted spacer fabrics are double - faced textiles in which the warp-knitted fabric surfaces are kept at a distance by connecting threads that maintain a spacing , so-called pile threads. The spacer fabrics are knitted fabrics or knitted fabrics that have been expanded to include the third dimension.

Manufacturing

The production of spacer fabrics is carried out on double raschel machines ( warp knitting machines ) with two needle bars in one operation. In contrast to weaving technology , the textiles are produced solely using warp thread systems, so no additional weft thread is required. Up to 7 thread systems are common in double-raschel machines for the production of spacer fabrics.

The stitch-forming elements represent latch needles or compound needles in connection with perforated needles. The warp threads are inserted through the perforated needles into the latch or compound needles in a manner appropriate to the binding. With every revolution of the machine, the stitch is formed on a needle bar on all needles at the same time. Here, the warp knitting technique is different from knitting , in which the formation of the loops takes place continuously one after the other and not simultaneously.

Types / ties

The two product surfaces can be designed identically or have different patterns from one another.

As a standard bonds for the production of closed outer surfaces are tricot , cloth or twill weaves are preferred. As a rule, a monofilament is used as the spacing thread , with polyester being mostly used as the base material. This spacing monofilament thread (pile thread) is mostly laid in a cross shape between the textile cover surfaces with a crossing angle of approximately 45 °. This ensures good resistance to movement of the textile outer surfaces in relation to one another and prevents the structure from tilting under pressure.

The polyester monofilament thread can be stabilized by subsequent finishing processes (thermal treatment) in such a way that permanent flexural elasticity is guaranteed and the knitted fabric has an elastic compressibility similar to that of a foam.

Thanks to the infinitely variable adjustment options on the machine in specified areas, the knitted spacer fabrics can be manufactured in almost any desired thickness, whereby so-called high-distance knitted fabrics can be manufactured up to a thickness of 65 mm. The usual adjustment ranges on the machines range from 1.5 to 12 mm or from 15 to 50 mm.

properties

Due to the large number of thread materials that can be used at the same time (in practice 5 to 7), there are many design options.

The most important properties of the spacer fabrics are: possible moisture management function, good pressure relief, thermoregulation , very good air permeability and other special functions that can be controlled via specific material use. These include bioactive effects, flame retardancy and also defined elastic behavior in the longitudinal and transverse direction.

In the field of smart textiles, it is also possible to integrate electrically conductive yarns, either to transport data or to generate defined heat by electrical means.

The use of various functional material components in a spatial structure and variable specific construction features significantly expand the range of physical and clothing physiological properties that can be achieved compared to classic woven, non-woven or knitted structures.

Examples

The high-distance structures are used in the fields of medicine, sports, automobiles, clothing, technical applications in industry and geotextiles. Concrete implementations can be found in:

- Car seats

- Climate feed

- 3-D compression bandages

- Protectors

- Orthotics

- Epithesis pads

- Mattresses

- Mattress covers

- Pillow

See also

literature

- Petra Knecht (Hrsg.): Functional textiles - high-tech products for clothing and home textiles . ISBN 978-3-87150-833-2