Gold leaf

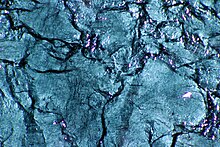

Gold leaf or gold foam is the name for a thin foil made of pure gold or high-quality gold alloys . It is used to create the impression of solid gold ( gilding ). In incident light, gold leaf shines golden yellow, in the backlight a white light source shines greenish-blue through.

Manufacturing

Pure gold or gold alloys are melted and poured into 2–5 millimeter thick zaine (bars). Additives ( platinum , silver , copper ) give the gold leaf the desired color. The teeth are then forged while still glowing and annealed several times in order to preserve the suppleness of the gold. Then it is rolled into a gold ribbon about the thickness of newsprint (approx. 30 micrometers) and cut into squares (quarters) . 400 to 500 of these quarters are placed one on top of the other in a squeeze between parchment paper and repeatedly beaten to about a micrometer with a spring hammer by the so-called gold beater while turning . After being quartered, the leaves are now in a gold beater shape, between layers of prepared ox caecum (so-called gold bat skin ), dusted with the finest plaster of paris, with increasingly heavy hammers in laborious manual work. The still useful fineness of the approximately 80 by 80 (but also 60 to 120) millimeter gold leaves is then 100 to 110 nanometers .

After the knocked out thickness, the gold leaf becomes

- Single gold (approx. 100–110 nm)

- often not specially marked as single gold. If a gold leaf is not expressly marked as particularly durable or double , it is single gold .

- Double gold (approx. 200–220 nm)

- popular for outdoor work because of its thickness and low porosity.

- Triple gold (about 300-330 nm)

- used for particularly stressed external gilding.

One gram of gold results in the ordinary thickness of 0.1 microns (100 nanometers), an area of about half a square meter. In the Roman era the thickness was around three micrometers, in the 14th century it was one micrometer.

The German center of this craft is Schwabach . There, in a simulated gold beater workshop in the city museum, a gold beater master demonstrates the production of gold leaf.

Other forms

- Storm gold

- Storm gold is gold leaf applied to tissue paper for gilding outdoors, i.e. H. for outdoor use (e.g. fonts for tombstones). Other expressions for this are: peelable gold , transfer gold or tower gold . It is usually placed in an adhesive bed and then cleaned, but it cannot be polished to a full gloss.

- Intermediate gold

- In the case of intermediate gold, only one side of the foil is made of gold, the other side is made of silver. It is therefore cheaper than gold leaf, but tarnishes over time.

For more gold-like alloys, see leaf metal and rusty gold .

Application technology

A distinction is made between oil gilding, glue gilding and poliment gilding:

- Oil gilding

- A distinction is made between weatherproof oil gilding (adhesive is the so-called mixtion, a drying oil consisting of linseed oil , black lead and turpentine oil ),

- Glue gilding

- For glue gilding, organic glue on a chalk base is used as an adhesive.

- Poliment gilding

- In the case of poliment gilding, the background consists of a chalk base or a fine bolus mixed with organic glue . Applied to this, the gold leaf can be polished to a high gloss with polishing stones.

Shoot up

Gold leaf requires a smooth surface on the subsurface. The carrier material is finely sanded because you can see every scratch through the thin film. Depending on the purpose and the desired effect, a special adhesive is applied (see the three types of gold plating). The gold leaf is then applied with a brush. The brush is electrostatically charged by rubbing it against the body in order to absorb the fine gold foil. The foil is applied to the object to be gilded with a single brush swab. This step is called "shooting up". The gold is then left dull or polished to a shine with a polishing stone or a hard object. The teeth were used for this in the past.

Application examples

Gold leaf is mainly used for gilding of picture frames , books ( Gold section , Illumination ), furniture, figures, architectural elements, stucco , icons etc. are used. At some Buddha statues in Myanmar , pilgrims were allowed to wear gold leaf as a sign of their reverence. In particular, the five statues of the Phaung Daw U Pagoda have been covered with gold in such a way that their original forms can hardly be recognized.

In Buddhism , gold leaf is used for ritual sacrificial acts .

Consumption of gold leaf is harmless and, for example, drinkable in Danziger Goldwasser , Schwabacher Goldwasser , as gold leaf on the opera cake or as a flavored drink containing wine (for example: Goldcuvée with gold liqueur or Austria Gold from Inführ Sekt ). 22- carat gold leaf is also used as a food coloring agent E 175 for gilding food and is used for body painters in make-up and in cosmetics in general for special effects.

In Atlanta , gold leaf was used to decorate the top of a skyscraper . The Bank of America Plaza , completed in 1993, has some gold-plated elements on its spire. The structure is 317 meters high.

Web links

- Gold leaf, a touch of nothing - ARD video on production and use (6:13)

Individual evidence

- ↑ Justus Freiherr von Liebig, JC Poggendorff, Fr. Wöhler (Ed.): Concise dictionary of pure and applied chemistry . 3rd volume. Braunschweig 1848, p. 670 ( limited preview in Google Book search).

- ↑ Kurt Sponsel, WO Wallenfang, L. Waldau: Lexicon of Painting Technology 1 . 8th edition. Callway, Munich 1987, ISBN 3-7667-0853-8 , pp. 389 ff .