loom

A loom is a mechanical device used to make fabrics . According to DIN ISO 5247-1, the designation “loom” is reserved for a manually operated weaving device. In fact, however, the term loom is used in everyday language and often also in specialist literature for all weaving devices, including weaving machines .

history

Since the forerunners of our looms were made of perishable materials, there is little evidence of their appearance. One is therefore dependent on prehistoric texts, pictorial representations and excavations. Although there is no reliable information, it is assumed that the chain was originally stretched horizontally, then moved to the vertical arrangement and finally returned to the horizontal one. However, some researchers consider the vertical weight loom to be the oldest loom. This loom was very widespread, but whether this construction is older than the peg loom, which is particularly common among nomads , or the back strap or hip loom , which can be proven early on in China , cannot be answered exactly either.

The existence of weaving techniques can be indirectly proven as early as the 7th millennium BC, since weaving pattern-like geometric wall paintings in the Turkish Tell of Çatalhöyük are strongly reminiscent of woven kilims . Also from about 6000 BC. Common ceramic painting, which spread from Anatolia via Southeastern Europe ( Sesklo , Karanovo , Starčevo culture ) to Central Europe ( linear ceramic tape ), sometimes shows geometric patterns, as are typical for weaving or braiding techniques. Ceramic looms for weight looms have also been found at sites of these cultures . The upright weight loom found widespread use in various regions early on. The Teutons and Celts made fabric on it in Central Europe during the Iron Age . Evidence of the use of the weight loom in the regions north of the Alps exists in the form of a vase drawing from the Hallstatt period found in Sopron , Hungary. This type of loom can also be found in Greece, Crete, Cyprus and the Middle East. Depictions on vases from the 6th – 4th centuries century BC prove this. This loom is even believed to have been used in ancient China, but there is very little evidence of it.

The oldest illustration of a horizontal weaving frame is an incised drawing on the inside of a ceramic bowl from the Badari site (Egypt) ; it dates from around 4400 BC. Dated. The bowl (Badari, grave 3802) is exhibited together with flax remains of the same age in London's Petrie Museum of Egyptian Archeology . From the Middle Kingdom (2137–1781 BC) in Egypt, which roughly coincides with the Early Bronze Age in Central Europe, there is a model scene from the tomb of Meketre showing the weaving with horizontal looms. This weaving device was not only used in Egypt, but probably originally came from the northern part of the Fertile Crescent , from where it also spread to India.

In China, the back band or hip loom was probably the first loom that also belonged to the horizontal weaving technique. The warp threads were stretched between two parallel wooden sticks. The "warp tree" was tied to a post or tree, the "goods tree" was attached to a strap that the weaver had placed around her waist. Moving the body made it possible to loosen or tighten the chain. The weaver could also hold the warp beam directly with her feet by the seated weaver. The back loom has also been proven in other countries in Indochina and also in Japan, and these simple weaving devices can also be found among the natives of South America. But in China already revealed for the Warring States period (475-221. Chr.) And the Han period the first evidence of the use of an oblique loom with running devices on which the weavers with their feet by stepping on pedals (kicks ) raised and lowered the shafts connected by cords and the warp threads drawn into them. The shed was formed. The web performance could be improved significantly.

The introduction of the step loom in Europe probably began in the 11th century. There was no fundamental change in weaving technology until around the middle of the 18th century. By then the step loom had replaced the vertical weight loom. But the invention of the “flying shooter” by the Englishman John Kay brought about three times the performance of the loom (approx. 40 m wefts per minute) compared to the standard at the time. The shuttle with weft yarn is "shot" through the shed with so-called drivers. The drivers are located on both sides of the loom in the rifle box, connected to a cord device. The weaver sets the driver in motion with a jerky pull on the cord. Edmond Cartwright designed the first mechanized loom in 1785 with the invention of the so-called power loom . The (hand) looms that have hitherto been used exclusively were replaced relatively quickly by looms, particularly in industrialized countries. A fifteen-year-old boy was said to be able to operate two looms and thus achieved about three and a half times the performance of a hand weaver.

Construction of a flat loom

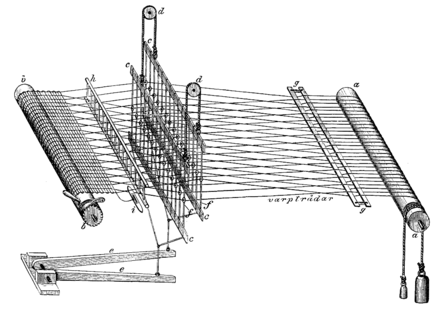

In a flat loom, the warp threads run horizontally. They are unwound from the warp beam (a) and transported to the goods tree (b). In the middle of the loom, two shafts (c) are arranged across the warp threads. Each shaft consists of an upper and a lower horizontal support rail, which are connected with wires. A row of strands (f) is suspended vertically from each shaft . The warp threads run through the so-called eyes (openings) in the middle of the strands.

The mechanism lifts one shaft and simultaneously lowers the other shaft. With the shafts, the strands and thus also the warp threads are moved up and down at the same time: While one warp thread is raised, the neighboring warp threads are lowered. This spreads the chain (totality of the warp threads) and forms a compartment for the shooter (i), also known as the "shuttle". The weft thread is inserted across the warp threads by the weft with the shuttle (illustrative video: see).

The weaver sheet (h) is located between the shafts and the goods tree. After each shot, the weaver blade is moved towards the goods tree. The weaver blade presses the newly inserted weft thread against the already finished fabric and presses the threads together.

A similar illustration of the same structure can also be found under Structure and Function of a Simple Loom .

Loom in the 3rd millennium

- In some developing countries there are still more hand looms in operation than commercial looms. In India in 2010 more than 7 billion m² of fabric were produced on approx. 2.4 million handlooms (over 80% share of global capacity). New looms are offered in India for around 1000 euros.

- In Europe there are only designer weaving workshops for exclusive products.

- Employment of supervised persons in charitable and educational institutions.

- Private individuals practice hand weaving as a hobby.

Individual evidence

- ↑ DIN ISO 5247-1: Textile machines and accessories - Weaving machines - Classification and terms, May 2005.

- ↑ authors: weaving technique, employers circle Gesamttextil, Frankfurt / Main 1988, ISBN 3-926685-39-5 , pp 00:02

- ↑ Erika Arndt: Weaving manual - history, materials and techniques of hand weaving. 2nd, revised edition. Haupt Verlag, Bern 2014, ISBN 978-3-258-60102-1 , p. 10.

- ^ Hugo Glafey: The textile industry. The manufacture of textile fabrics . Verlag von Quelle & Meyer, Leipzig 1913, pp. 43/44.

- ↑ Stefan Mecheels, Herbert Vogler, Josef Kurz: Culture and industrial history of textiles . Wachter GmbH, Bönnigheim 2009, ISBN 978-3-9812485-3-1 , p. 70.

- ^ LBK: Ralph Einicke, Linienbandkeramik (LBK). In: Hans-Jürgen Beier and Ralph Einicke (eds.), The Neolithic in the Middle Elbe-Saale area and in the Altmark. An overview and an outline of the state of research . WILKAU-HASSLAU 1994, 30

- ↑ Stefan Mecheels, Herbert Vogler, Josef Kurz: Culture and industrial history of textiles . Wachter GmbH, Bönnigheim 2009, ISBN 978-3-9812485-3-1 , p. 71 /.

- ↑ Erika Arndt: Weaving manual - history, materials and techniques of hand weaving. 2nd, revised edition. Haupt Verlag, Bern 2014, ISBN 978-3-258-60102-1 , p. 13.

- ^ EJW Barber: Prehistoric Textiles . Princeton University Press 1991, ISBN 0-691-00224-X , p. 83.

- ↑ Almut Bohnsack: Spinning and Weaving - Development of Technology and Work in the Textile Industry. Rasch Verlag, Bramsche 2002, ISBN 978-3935326810 , p. 44.

- ↑ Illustration of the model in the tomb of Meketre , source: UCL website

- ↑ Stefan Mecheels, Herbert Vogler, Josef Kurz: Culture and industrial history of textiles . Wachter GmbH, Bönnigheim 2009, ISBN 978-3-9812485-3-1 , p. 67.

- ^ EJW Barber: Prehistoric Textiles . Princeton University Press 1991, ISBN 0-691-00224-X , p. 90.

- ^ EJW Barber: Prehistoric Textiles . Princeton University Press 1991, ISBN 0-691-00224-X , pp. 80/81.

- ↑ Stefan Mecheels, Herbert Vogler, Josef Kurz: Culture and industrial history of textiles . Wachter GmbH, Bönnigheim 2009, ISBN 978-3-9812485-3-1 , page 71/73.

- ↑ Stefan Mecheels, Herbert Vogler, Josef Kurz: Culture and industrial history of textiles . Wachter GmbH, Bönnigheim 2009, ISBN 978-3-9812485-3-1 , p. 98, p. 210.

- ↑ John Kay - Famous Inventor (English)

- ↑ Power Loom spartacus-educational.com (English)

- ↑ How does a loom work? Video with a clear explanation, created in the LVR-Industriemuseum Euskirchen ( cloth factory Müller ).

- ↑ Note on Handloom Sector Government of India, Ministry of Textiles, December 30, 2015 (English)

- ↑ Offers of new looms in India (example)

- ↑ Example: jacket manufacture in Hamburg , carpet weaving mill in Basel

- ↑ Example of hand weaving in a socio-therapeutic institution: Himmelkey Court Texing /