Reel (mining)

As reel in are mining all the pulling and hoisting winches for actuating pull and haul ropes referred. As early as the beginning of the 12th century, reels were used in mining to lift and move loads in shafts .

history

As early as 1168, conveyed goods were transported in seigeren shafts with the help of hand reels . These reels were driven by the muscle strength of the miners that one reel servants called. However, these reels were only suitable for a depth of 45 to a maximum of 100 meters, and no large loads could be transported with them. In order for loads over 100 kilograms to be lifted, these machines had to be equipped with up to four reel pullers, which made them very labor-intensive. From the 15th century onwards, when the company ventured into greater depths, these manually operated lifting machines were gradually replaced by more powerful göpeln that were driven by water power. From the 19th century, hand reels made of steel with a gear drive with transmission were used in the Freiberg mining area. With the increased use of compressed air in mining, reels powered by compressed air were used underground. Even today, reels are still used in the coal mining industry as drive means for floor conveyors, overhead monorails and as drive machines for blind shaft hoisting machines . Compressed air driven machines are used for smaller reels and electric or electrohydraulic drive machines for larger machines.

Reel powered by muscle power

Hand reel

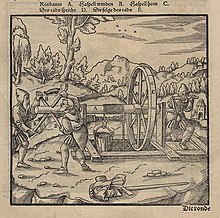

In his 12 books on mining and metallurgy “De re metallica libri XII” Agricola already describes several different hand reels. Depending on the drive mechanism, a distinction is made between four hand reels:

- the common horn or mountain reel

- the flywheel reel

- the cross reel

- the countershaft reel.

Horn reel

The horn reel consists of a construction of two supports called the reel supports or reel chair. The ends of the reel supports are provided with slots that are reinforced with iron. In addition, the horn reel has a round tree as a shaft, with a pin attached to each end. These tenons are set into the circular tree about eight inches deep. The pins are forged flat at the ends that protrude beyond the bearings. The round tree has its greatest strength at the cones. With these pegs the round tree rests on the slots in the reel chair. The distance between the reel supports is determined by the required length of the round tree, which in turn depends on the number of rope turns and the diameter of the hoisting rope. A lateral surcharge of one foot is added to this length . The irons in the slots are called path irons, they serve as bearings for the tenons. So that the round tree cannot jump out of its bearings, a cotter pin or a nail is stuck across the path iron over the pin, this pin is called a linchpin. The average length of the round tree is about seven feet, the diameter of the round tree is eight to nine inches for the two-man reel and 10 to 12 inches for the four-man reel. The distance between the path iron and the hanging bench is about 40 inches. The height of the reel supports, at which the reel worker can optimally use his physical strength, is 60% of the body size of the reel worker. The diameter of the round tree depends on the load to be transported and the depth of the shaft. The hoisting ropes are wound onto the round tree .

The hauling rope is attached to the round tree by means of a rope clamp, and a loop is created at the end of the rope over which the rope clamp is wrapped. A so-called wave thumb, which consists of two bent bolts, is attached to the ends of the round tree so that the rope does not wind up over the wavelength and thus get into the pin. The required rope length and the diameter of the round tree determine the number of rope turns. In order to compensate for the weight of the feed bucket, the round trees are often designed conically. Where space is possible, two hoisting ropes are attached to the round tree with a hoisting bucket at each end. As a result, the secondary load of the bucket is at least partially balanced. For operation with two conveyor buckets, the conveyor ropes are wound onto the round tree in opposite directions. This also moves the buckets in different directions: while the full bucket is pulled up, the empty bucket is transported into the pit. There is a lever on each of the tenon wings, the reel horn. These reel horns are used to turn the round tree. The reel horns consist of a twice bent iron that is flattened on one side. With this flat side the reel horn is attached to the round tree. On the other hand, the reel horn is shaped like a round bar so that it can slide better through the hand. The arm of the reel horn is about 18 to 20 inches, and the handle is about 16 inches long. The length of the crank arm is optimal if the handle of the reel horn does not protrude over the shoulders when it is at its highest and not below the knee of the reel worker when it is at its lowest. The reel horns form a lever through which the force is exerted on the round tree. The force to be applied is related to the attached load like the radius of the round tree to the length of the reel arm. The thinner the round tree and the longer the reel arm, the less effort is required. However, the length of the crank arm of the reel horn and the diameter of the round tree can only be varied within narrow limits. Since a crank arm that is too long can only be handled very poorly by the reel puller, the length of the reel horn can only be extended to a limited extent. With thicker round trees there is significantly less overturning of the hoisting ropes, so that thicker round trees are more advantageous than thinner ones.

The entire construction is built on the reel frame. The reel frame consists of four wooden planks which, when assembled, form an elongated square. The two pieces of wood on the long side are called hanging benches, and the two pieces of wood on the short side are called feel trees. The feel-trees consist of 10 to 11 inch thick beams that protrude on both sides of the shaft disc. The hanging bank consists of two-inch planks that are nailed onto the pfeel trees. A strip is nailed on close to the edge around the manhole opening so that nobody can slide into the manhole when ice forms, especially in winter. Usually there is a cover over the shaft opening, the reel door. It is used to ensure that objects that are on the hanging bench cannot be pushed into the shaft without further ado. The reel supports are attached to the middle of the sensor trees. The reel supports are pegged vertically into the feel trees. A smooth bar, called a weir bar, is attached to the reel supports parallel to the round tree. This rod is used to support the reel puller who pulls the conveyor bucket. The weir bar is dimensioned so strongly that it does not bend or break when it is counter-chiselled. For this reason, it is mostly made of iron, which, however, has a disadvantageous effect in winter due to the change in length of the reel wood.

The horn reel is the most widely used of the hand reels used in mining. It was mainly used for mining in shafts. If the horn reel was mainly used to lower loads, it was connected to a braking mechanism (Premswerk). This braking mechanism consists of two round discs made of strong planks, which are attached close to each other on the round tree. Lever arms with so-called compass pieces are attached over the two discs . By appropriately pressing the lever arms onto the disks, the movement of the downwardly driving conveyor bucket is delayed.

Flywheel reel

The flywheel reel is constructed similarly to the horn reel. In addition, the flywheel reel has a flywheel at one end outside the reel supports, directly on the round boom or on the extension of the lead cone. A rotating ring or capstan is attached to one of the spokes of the flywheel . There is a reel horn on the opposite side. Due to the increased friction , more force is required to move the flywheel reel than the horn reel. This way the advantages of the flywheel are outweighed by the disadvantages. Tests have shown that the reel pullers with flywheel reels could do less than with ordinary horn reels. There are mutliple reasons for this. First of all, the effect of the flywheel is not fully effective due to the unfavorable positioning of the flywheel at the shaft end. In order to be able to use the effect optimally, it would have to be positioned in the middle of the shaft, which is not possible. In addition, a higher force must first be applied in order to start the flywheel reel. Once the reel is started, it can only be stopped with additional effort due to the rotational energy stored in the flywheel . This is very disadvantageous in the event of a malfunction during driving and requires a special effort to brake the reel. In addition, the weight of the flywheel has an adverse effect on the running properties of the reel, since it slightly increases the friction. The advantages mainly come into play with deeper shafts.

Cross reel

With the cross reel, the shaft is moved by inserted arms. In principle, it is constructed in the same way as the horn reel, however so-called reel winches are attached to the ends instead of the reel horns. The reel winches consist of round pieces of wood that are inserted crosswise through the round tree, with which the round tree is rotated. This type of hand reel has not proven itself in mining.

Countershaft reel

With the countershaft or gear reel, the power is not transmitted directly from the reel horn to the round boom, but via a second shaft called the countershaft. This back gear is provided with a gear that meshes with a gear attached to the round boom. This construction makes the countershaft reel suitable for transporting larger loads. Countershaft reels have a greater friction than normal reels without a countershaft due to the friction of the teeth and the bearing friction of the necessary shafts of the countershaft. In the case of smaller horn reels, the use of a back gear does not bring any advantages, since a corresponding construction of the reel horns and the reel shaft, due to the leverage of the reel horn, also requires less force. The benefit of a back gear only comes into play when larger loads have to be transported and thus the length of the reel horns would exceed a certain size. Other reasons for using lay reels are conveying from greater depths and the rope knocking over, which can occur with thinner round trees. In addition, when using larger conveying vessels, a lay-on reel is advantageous if the use of a cap is not profitable for reasons of cost. However, lower conveyor speeds are achieved with lay- on reels than with reels without a lay-up.

Impeller reel

With the impeller reel, an impeller attached to the side of the round boom is used as a drive. This impeller consists of two parallel rings that are connected to the round tree by arms. Planks or strong strips are attached to the side of the wheel rims. Bars are nailed to the planks around the entire circumference of the wheel so that people or animals can move on them. The size of the running wheels depends on which animals should move in the running wheel, as they must be able to stand comfortably under the wheel axle. The impeller must be about 18 to 20 inches wide on a human and eight feet wide on animals. The impeller is moved by the weight shift exercised by the moving people or animals. The wheel rim is designed to be as narrow as possible so that the lever arm of the force is shortened as little as possible. A compromise is required between durability and power transmission, to which the wheel rim is matched for a given wheel size. The optimal place in the running bike where humans or animals can drive the bike most easily and best is determined by the angle of inclination of the step. The optimal angle of inclination for the least amount of stress when walking is 30 degrees for humans and between 16 and 30 degrees for animals.

Due to its size, the impeller doubles as a flywheel so that the movement of the impeller is relatively uniform once it is started. Differences in load can be compensated by having the people driving the wheel move closer to the bottom of the wheel or move away from the bottom of the wheel. However, if the load jumps off the rope, it has a problematic effect on the running behavior of the bike, in which case it can happen that the bike starts to swing too much. If the load becomes very overweight, the impeller can suddenly swing back. For these cases, the running wheels are equipped with special braking mechanisms or braking devices that bring the running wheel to a standstill when triggered.

Pedal reel

The construction of the pedal reel is identical to the impeller reel, the only difference in construction is the tread. Instead of the continuous running surface, as is the case with the wheel reel, step boards or steps are attached to the planks attached to the side of the wheel rim. As a result, people and animals walk in the pedal bike like on stairs. Just as with the running wheel reel, the angle of inclination of the legs is crucial for the optimal use of muscle strength. The optimum angle is reached when the feet are 90 degrees from the lowest and highest point of the wheel periphery. About 7/8 of the weight of the person is used for the rotary movement of the reel, 1/8 of the body weight remains unused. This is due to the fact that, on the one hand, people have to hold on to the wheel rim and, on the other hand, the alternating movement of their feet. In animals, only half of the weight is used. The number of running boards depends on the height and inclination of the step, the height of the running boards must not exceed 12 inches in humans. For animals, the height of the rungs is between 9 and 15 inches. The pedal reel is less suitable for animals, as it is considerably more difficult to optimize the pedal for them in order to make the most of their strength. But the pedal reel is also much more tiring than the impeller reel for humans. The pedal reel was used much less than the impeller reel.

Mechanically operated reel

Water wheel reel

The basic construction of the waterwheel reel is very similar to the horn reel. There are differences in the type of drive. Instead of the reel horns, there is a water wheel connected to a shaft on the side of the round tree cone . So that the reel can be moved in both directions, a sweeping wheel , this is a double-padded water wheel, is used. A prerequisite for the operation of a water wheel reel was that there was a body of water in the vicinity that provided enough water for the water wheel. However, these reels were only used very rarely, and if so, only in larger mines.

Tractor reel

The tractor reel consists of a frame, a drive motor, the gearbox, the brake and the cable drum. Either electric or compressed air motors are used as motors. Squirrel cage motors are predominantly used in electric drives . Since these motors start up quickly, a planetary starting gear with a slip clutch or an exchangeable multi-plate clutch is installed to protect the cable and the gear. Straight-tooth motors are used for reels with compressed air drive and arrow-wheel motors for larger reels. When gears are worm gear or a double gear or spur gear used. As a rule, grinding brakes are installed as brakes. For use on sloping or undulating stretches, tractor reels with self-locking load brakes or with worm gears are used. The brakes are designed either as single or double shoe brakes or as band brakes. The brake is operated by a hand wheel or a lever and applied by an interposed spring. There are also reels where the brake has to be released using a pedal. The brake is designed in such a way that it applies as soon as the brake pedal is released. In the case of small reels, a rope with a length of 150 to 700 meters can be wound onto the rope drum. The length of the rope that can be reeled depends on the drum and rope diameter. The rope diameter used is 4 to 7 millimeters for smaller reels, 10 to 13 millimeters for medium reels and 13 to 16 millimeters for large reels.

Reel at the Renate colliery in Muttental

Conveyor reel

Conveyor reels are used for conveying in blind shafts. A distinction is made here between pure load reels and reels, which are also approved for passenger transport .

Small conveyor reels are only used to convey loads during sinking or exploration work or for transport between two levels . They are suitable for small individual loads at higher speeds. They consist of a base frame, a drive machine, the gearbox and the brake. A compressed air motor, usually a twin machine, is used as the drive motor. The motor drives a gear reduction. The drive pinions can be disengaged so that loads can be braked when the machine is at a standstill. Either cast steel drums with oak wood covering or cast iron spiders with a sheet metal jacket are used as the rope drum. The sheet metal jacket of most reels has a wooden covering. As a rule, continuous drums are used, split drums are rarely used. A band brake with a wooden lining is used as the brake, which acts on a brake ring attached to the cable drum. Occasionally two band brakes are installed. The brake is always applied by a weight and has to be operated by a hand lever or a pedal to release it.

Conveyor reels with medium power are used as drives for blind shaft conveyor systems. For outputs of up to around 110 kilowatts, compressed air twin-piston motors are used as the drive motor; for higher outputs, electric motors are used. In the case of reels operated by compressed air, the high consumption of compressed air is a disadvantage, which is all the more serious the longer the reel is operated per day. Electrically driven reels can be monitored with electrical controls and, like hoisting machines on main shafts, are equipped with a safety brake that is triggered when the maximum speed is exceeded. Conveyor reels are suitable for a permissible travel speed of up to 4 . Conveyor reels are equipped with a conveyor reel locking device that prevents the conveyor reel from being unintentionally started. This locking device is used to protect people and the system. As Cords are traction sheaves used. Drums as cable carriers are less suitable, as conveyor reels with drums require a larger reel chamber. Since the permissible rope deflection angle must not be undercut, a greater distance between the conveyor reel and the sheave is required for the drum than for the traction sheave. As a result, the cable channels become longer and the foundation has to be laid out heavier. In addition, due to the convergence underground, it is possible that the conveyor cage can be jammed in blind shafts with strong rock pressure . While the hoisting rope slips on the traction sheave on reels with a traction sheave , the rope is blocked briefly on drum reels and can form kinks that severely damage the rope. A bobbin is used as a cable carrier for conveyor reels that are used for sinking .

Individual evidence

- ^ A b Walter Bischoff , Heinz Bramann, Westfälische Berggewerkschaftskasse Bochum: The small mining dictionary. 7th edition. Glückauf Verlag, Essen 1988, ISBN 3-7739-0501-7 .

- ↑ a b c d Wolfgang Weber: Hemp conveyor ropes in the 18th – 19th centuries Century, manufacture and strengths. In: Bergknappe. 90, pp. 19-23. ( online ( memento of December 12, 2013 in the Internet Archive ), last accessed on October 25, 2012; PDF; 4.7 MB).

- ^ Johann Friedrich Lempe: Magazine for mining science, Fifth Part. Waltherische Hofbuchhandlung, Dresden 1788.

- ^ The development of mining in the Freiberg district. (last accessed October 25, 2012).

- ↑ a b c d e Franz Rziha: Textbook of the entire art of tunneling. First volume, published by Ernst & Korn, Berlin 1867.

- ↑ a b c d e Mining dictionary. Johann Christoph Stößel, Chemnitz 1778.

- ↑ a b c d e Fernand Stamm: Small school of mining. Karl Andre 'publishing house, Prague 1853.

- ↑ a b c d e f g h i G. Hassel, AG Hoffmann (Hrsg.): General Encyclopedia of Science and Arts in alphabetical order. Second Section HN, Third Part, published by Johann Friedrich Giebitsch, Leipzig 1828.

- ↑ a b c d Georg Gottlieb Schmidt: Beginnings of Mathematics. Second part, second division, hygraulics and mechanical engineering, published by Barrentrapp and Wenner, Frankfurt am Main 1799.

- ↑ Explanatory dictionary of the technical terms and foreign words that occur in mining in metallurgy and in salt works and technical articulations that occur in salt works. Falkenberg'schen Buchhandlung publishing house, Burgsteinfurt 1869.

- ^ A b Carl Johann Bernhard Karsten: Archives for mining and metallurgy. Seventh volume, published by G. Reimer, Berlin 1823.

- ^ Karl Christian von Langsdorf: Detailed system of the machine customer. Second volume, second and last division, published by Karl Groos' new academic bookstore, Heidelberg / Leipzig 1828.

- ^ Emil Leo: The prospecting, extraction and mining of lignite. Printed and published by Gottfried Basse, Quedlinburg / Leipzig 1854.

- ^ A b c d Johann Heinrich Moritz Poppe: Textbook of machine technology. Published by CF Osiander, Tübingen 1821.

- ^ Heinrich Veith: German mountain dictionary with evidence. Published by Wilhelm Gottlieb Korn, Breslau 1871.

- ↑ a b H. Hoffmann, C. Hoffmann: Textbook of mining machines (power and work machines). 3. Edition. Springer Verlag, Berlin 1941.

- ^ A b c Carl Hellmut Fritzsche: Textbook of mining science. First volume, 10th edition. Springer Verlag, Berlin / Göttingen / Heidelberg 1961.

- ^ Siegfried Sommer: Technik Wissen 1900–1915 Volume 9 Hoisting machines / mining / iron and steel ships. ISBN 3-937081-13-5 .

- ↑ TAS / September 1996, sheet 11/1: Definitions (last accessed on October 25, 2012).

Web links

- Unknown mining in Saxony: Examples of different reels (last accessed on October 25, 2012)

- Principle of the flywheel reel (last accessed on October 25, 2012)