Indium tin oxide

| Crystal structure | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||

| __ In 3+ / Sn 4+ __ O 2− | |||||||||||||

| General | |||||||||||||

| Surname | Indium tin oxide | ||||||||||||

| other names |

ITO |

||||||||||||

| Ratio formula | (In 2 O 3 ) 0.9 (SnO 2 ) 0.1 | ||||||||||||

| Brief description |

white to yellowish solid |

||||||||||||

| External identifiers / databases | |||||||||||||

|

|||||||||||||

| properties | |||||||||||||

| Molar mass | 264.94 g mol −1 | ||||||||||||

| Physical state |

firmly |

||||||||||||

| density |

7.12 g cm −3 (25 ° C) |

||||||||||||

| solubility |

almost insoluble in water |

||||||||||||

| safety instructions | |||||||||||||

|

|||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||||||||

Indium tin oxide (English indium tin oxide , ITO ) is a semi-conducting , substantially transparent in the visible light material . It is a mixed oxide , usually made of 90% indium (III) oxide (In 2 O 3 ) and 10% tin (IV) oxide (SnO 2 ).

properties

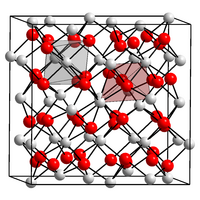

As a dopant, tin (IV) oxide produces the imperfections in the crystal structure of the indium oxide that are necessary for good electrical conductivity. Deposition on glass at substrate temperatures of approx. 400 ° C is typical. The crystal structure of the indium (III) oxide is retained when doped with tin.

Thin layers of 100 nm have a sheet resistance of typically 15 Ω, layer thicknesses of e.g. B. 15… 300 nm. Float glass (1.1 mm) coated with 100 nm ITO has a transmission of approx. 84… 89% in the visible wavelength range (400… 700 nm) .

application

The fabric is used for the production of transparent electrode in liquid crystal displays , organic light emitting devices , touch screens , thin film solar cells , photodiodes , and electrochromic applications used.

ITO is also used to produce invisible or transparent conductor tracks on glass, for example for heated windows and microscope slides, invisible antennas or conductor tracks on CCD sensors .

A wide variety of surfaces, for example plastic films, can be coated with ITO so that they do not become electrostatically charged and still remain transparent.

ITO-coated panes can shield radio waves.

Since ITO strongly reflects infrared radiation, it is occasionally applied to window panes as thermal protection.

Coating process

ITO is usually applied to substrates under a high vacuum . Glasses and plastic films are used as substrates. Cathode sputtering is the most commonly used method, but it can also be applied by thermal evaporation , with evaporated components having to be heated to up to 360 ° C, which limits its applicability, especially with plastics. Vapor deposition at room temperature and subsequent aging in oxygen at 360 ° C. and atmospheric pressure is also possible. The layers look metallic after vapor deposition and are opaque. Only the oxidation gives them the desired properties of transparency and conductivity.

Another option is the sol-gel process , which can be used on thin but large layers. The substrates can be dipped, sprayed, printed or coated by spin coating. The disadvantage here is that the layer homogeneity is too low for many applications ( LCD and OLED ).

Alternative materials in the semiconductor industry

Because of the high price of indium, which has multiplied in recent years, ITO is relatively expensive. The limited quantities of indium that are available will, in the medium term, limit mass use in thin-film solar cells, for example. We are therefore working intensively on alternative, transparent, conductive coatings. Promising candidates include a .:

- SnO 2 : F, tin (IV) oxide doped with fluorine (English Fluorine Tin Oxide , FTO)

- ZnO: Al, aluminum- doped zinc oxide ( Aluminum Zinc Oxide , AZO)

- SnO 2 : Sb, tin (IV) oxide doped with antimony (English Antimony Tin Oxide , ATO)

- Graph

Individual evidence

- ↑ a b data sheet indium tin oxide from AlfaAesar, accessed on February 9, 2010 ( PDF )(JavaScript required) .

- ↑ Gunar Kaune: X-ray characterization of indium tin oxide thin layers . ( Memento of the original of February 14, 2006 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 4.4 MB) Diploma thesis, Chemnitz University of Technology , September 26, 2005.

- ↑ a b data sheet indium tin oxide from Sigma-Aldrich , accessed on April 5, 2011 ( PDF ).

- ↑ V. Senthilkumar, P. Vickraman, M. Jayachandran, C. Sanjeeviraja: Structural and optical properties of indium tin oxide (ITO) thin films with different compositions prepared by electron beam evaporation. In: Vacuum , 84, 2010, pp. 864-869, doi: 10.1016 / j.vacuum.2009.11.017 .

- ↑ a b https://www.pgo-online.com/de/katalog/ito.html

- ↑ https://www.pgo-online.com/de/katalog/kurven/pdfkurven/D/CEC020S40070011.pdf PDF spectral transmittance

- ↑ Time: Flexible Computers. September 6, 2011, accessed September 7, 2011 .