Control (steam engine)

The steam engine control , also called control for short , is the part of a piston steam engine that controls the flow of steam into and out of the cylinder. Through the change between inflow and outflow mediated by a slide or valve, the steam can do work in the steam cylinder and move the piston back and forth. The control influences the running and direction of movement of the steam engine by opening or closing the slide. By adjusting the valves or the degree of overlap of the slides, the driver of the machine can influence the filling of the cylinders and the expansion of the steam in the cylinder and thus determine to a certain extent the performance and speed of the steam engine as well as the economic efficiency of its operation.

A basic distinction must be made between the parts of the internal control and those of the external control.

In addition to the basic function in the interest of low steam consumption, the design goals of a steam engine control are quick opening and closing of the steam channels to the cylinder, low steam speeds and flow resistances, no harmful spaces and low heat losses of the steam when flowing through the internal control.

General structure, preliminary remark

In the following, the control designs of the steam engines of steam locomotives are essentially described. With regard to stationary steam engines, partly different building principles have been implemented.

Inner controls

Internal controls are those components that come into direct contact with the steam and influence its inflow and outflow into and out of the cylinder.

The central component of the internal control is often a slide. This can be designed as a flat slide (shell slide) or as a round slide (piston slide). The valve is surrounded by the vapor-tight valve body , which can be opened for maintenance and repair purposes. Additional valves are sometimes flanged to the valve body, which may be necessary for starting up the steam engine and for its idling with as little resistance as possible (pressure equalizer).

Instead of slides, however, valves can also be used.

Flat slide

The flat slide rests on a flat surface, the slide mirror , into which slot-shaped channels are incorporated, through which the steam can get into the cylinder and back out again. The channels are alternately connected to the steam supply and the exhaust by the slide movement. The pressure of the live steam rests on the slide from above and presses it tightly onto the slide. As a result, it can only be moved with considerable effort, which is a major disadvantage of the flat slide. On the other hand, apart from the pressure exerted on it, it rests loosely on the slide mirror and can lift itself off the surface and thus drain any condensation water from the cylinder even with closed channels. The latter is a great advantage of the flat slide valve, as it can prevent damage to the steam engine from water hammer.

Round slide

The round or piston valve is the cylindrical design of a valve. Instead of the flat surface of the slide mirror, the wall of the cylindrical slide bushing, which is pierced by the steam channels, occurs here. The actual slide consists of two piston bodies which, depending on the design, are either fixed or "floating" on a common slide rod . Since the steam pressure does not act on the slide body on one side, as is the case with the flat slide, but acts on both outer surfaces, piston slide valves can be moved relatively freely without great effort and regardless of the steam pressure. However, spool systems with a water hammer concluded vapor channels do not like to share a flat slide by "lifting" and must therefore be provided with additional fittings such as cylinder safety valves or rupture disks.

The piston valve is the most common type of internal control in European steam locomotives and can be found in a number of designs. A distinction is made between fixed control piston valves, in which the pressure compensation for the idling of the steam engine is made possible by external valves, and combined pressure compensation piston valves. The most well-known of these types are the Karl Schultz valve (Nicolai piston valve ), the Müller valve and the Trofimoff valve .

Valve control

Special features of the valve control

Instead of the relatively heavy flat or round slide valves, smaller and lighter valves, similar to those used in internal combustion engines, can also be used to regulate the steam inlet and outlet . The Lentz control and the Caprotti control are particularly known . The valve can be actuated via cam rods moving back and forth as well as via centrically or eccentrically oscillating or rotating camshafts.

While light poppet valves have to open against the steam pressure, double-seat valves (pipe valves) and piston valves are pressure-relieved. Compared to slide controls, valves offer the advantage of large inlet and outlet cross-sections, small harmful spaces and less throttling. They are therefore suitable for fast runners.

Lentz control

The Lentz control is named after its developer, the engineer Hugo Lentz .

Lentz control with upright valves and valve actuation via cam rods

(from Messerschmidt: Lokomotivtechnik in the picture )

In the most common Lentz valve control system, there are four valves in series above the steam cylinder. The two outer valves are used for the steam outlet, the two inner valves for the steam inlet. The valves are made of mild steel as double seat valves. The valve actuation head is screwed onto the hollow valve stem. The cam rod with the lift cams which actuate the valves is guided radially through this; the spring-loaded valve head rolls over glass-hard hardened rollers on the cam rod moving back and forth. The movement of the cam rod parallel to the piston is generated by an ordinary steam locomotive control according to Heusinger, but with an increased stroke in the interest of quick opening; the control can therefore also be handled like a normal slide control.

Due to the spring-loaded valves, no special equipment is required to protect the cylinder against water hammer. Furthermore, a particularly easy idling of the locomotive can be achieved by a special device in which the valve spindle head can be lifted from the cam rod by means of compressed air or steam and thus a permanent valve opening is possible. As an advantage over the spool control was also considered, the valve seat without expensive machine tools that can be reground and prone to leaks stuffing the spool accounted for.

Lentz control with oscillating centric camshaft

In this embodiment of the Lentz valve control, the valves are not actuated by a cam rod, but by a vertically oscillating (i.e. not constantly rotating in the same direction) camshaft lying parallel to the axis. The valves are arranged lying on the steam cylinder. The camshaft is driven from the drive axle via rods and a counter crank.

The Lentz control with oscillating centric camshaft was initially used in stationary steam engine construction, but then also in superheated steam composite locomotives from the Lanz company . It was first used in locomotive construction in Italy in 1906. One of the main advantages of this type of construction was the simpler manufacture of rotating components.

Lentz control with eccentrically oscillating camshaft

In contrast to the aforementioned camshaft design of the Lentz valve control, this valve spindle axis and camshaft axis do not intersect, but rather pass each other at a certain distance, i.e. eccentrically.

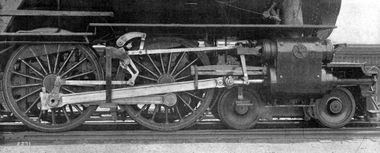

External controls

1 - counter crank , 2 - swing arm , 3 - control rod, 4 - hanging iron , 5 - throwing lever , 6 - control rod lever , 7 - swing arm , 8 - slide push rod , 9 - handlebar attachment on the cross head , 10 - slide rod guide , 11 - handlebar rod, 12 - advance lever , 13 - slide rod , 14 - piston slide

When external control is any mechanical drive organs, such as lever , cranks , eccentric or other transfer elements that move the components of the internal control. The control is derived directly from the movement of the steam engine piston to be controlled. The stroke of the slide and thus the degree of filling and even the direction of rotation of the steam engine can be changed by changing the lever ratios . One then speaks of a backdrop control . Valve controls are regulated by adjustable or sliding cams or camshafts .

Before convertible and controllable controls were developed, the steam locomotive could only be controlled with the steam regulator; To reverse the direction of travel, parts of the engine had to be relocated in laborious “manual work”, as can be seen from the description of the John Bull locomotive built by Robert Stephenson in 1831 .

Since the basic structure of the external control is independent of the internal control , control types are named after the structure of the external control .

Control types

Some types of steam control are:

- Stephenson control by Robert Stephenson (Great Britain, first half of the 19th century)

- Hackworth control by Timothy Hackworth (Great Britain, first half of the 19th century)

- Control of William T. James on a Baltimore and Ohio Railroad locomotive , (USA, 1832)

- Gooch Control by Daniel Gooch (Great Britain, 1843)

- Allan or trick control , by Josef Trick (Germany, mid-19th century)

- Heusinger control (English 'Walschaerts gear') by Egide Walschaerts (Belgium, 1844) or Edmund Heusinger von Waldegg (Germany, 1849)

- Joystick by David Joy (Great Britain, 1879)

- Gölsdorf angle lever control (Austria, late 19th century)

- Baker control (USA, 1903)

- Caprotti valve control by Arturo Caprotti (driven by rotating shafts, Italy, 1921)

- Gresley control by Nigel Gresley (Great Britain, first half of the 20th century)

- O&K patent control (Germany, first half of the 20th century)

Control arrangements

In steam locomotive construction , a distinction is made between internal control and external control with regard to the arrangement.

As internal control is meant that the control rod together with the slider boxes located in the inner area between the driving wheels is for example in the Prussian G 3 . In some cases the drive rod arrangement can also be located in this area. Often, but not necessarily, an external frame construction is also associated with this, which leaves enough space for the internal control, as for example with the MÁV IIIe .

When external control is meant that the control rod together with the slider boxes located on the outside next to the driving wheels. In most cases, the cylinders and the entire drive linkage are also arranged on the outside, as the control diagrams above show. In some cases, however, the cylinders and connecting rods can also be located inside, while the coupling rods are located outside, see for example the kkStB 9 .

literature

- Wolfgang Lübsen: Steam locomotive controls . In: Lok-Magazin . No. 74 . Franckh'sche Verlagshandlung, W. Keller & Co. , 1975, ISSN 0458-1822 , p. 378-380 .

- Friedrich Sass , Charles Bouché (Ed.): Dubbel s Taschenbuch für den Maschinenbau, Volume II . 11th edition, Springer Verlag Berlin / Göttingen / Heidelberg 1955, p. 100 ff.

- F. Meineke, F. Röhrs: The steam locomotive: teaching and design. Springer-Verlag, 2013, ISBN 978-3-642-86229-8

Web links

- Programs for checking various controls

- Program for the automated design of controls (online program for Firefox browser)

- Types of external control (Stephenson, Gooch, Allan, Heusinger)

Individual evidence

- ↑ Tieroff: Die Dampfmaschine, Volume I , Fachbuchverlag Leipzig 1956, page 164

- ↑ Max Heinrich Philipp Osthoff: Dissertation on valve control according to Lentz, TH Berlin, speaker: Obergehtmann, co-speaker: Stumpf, Berlin 1908, p. 12

- ↑ Hanomag-Nachrichten , Issue 100, p. 26 ff., February 1922: Description and instructions for handling the locomotives with Lentz valve control .

- ^ Erich Metzeltin : Locomotives with valve control, built by Hanomag, formerly Maschinenfabrik G. Eggestorff . Article in the VDI magazine, 1906

- ^ A b Max Heinrich Philipp Osthoff: Dissertation on valve control according to Lentz, TH Berlin, speaker: Obergehtmann, co-speaker: Stumpf, Berlin 1908