M. Joss & Lowenstein

M. Joss & Löwenstein was a Bohemian linen manufacturer with factories in Prague , Klattau and Neuern .

history

With the development of the industrial clothing industry from the mid-19th century onwards, companies producing lingerie for general sale emerged in England and France in the 1860s . In what was then Austria , Marcus Joss started in 1870 in a room on Wenceslas Square in Prague with two sewing machines and scissors for cutting, supported by ten unskilled workers. The goods produced found sales and the growing orders soon made it necessary to relocate and expand the business premises. The operation was in the Jungmannstrasse of the royal vineyardscontinued and after nine years of its existence had reached such an extent that Marcus Joss was no longer able to manage the company alone. Simon Löwenstein joined the company as a co-owner.

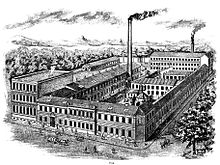

During this time, the products were sold abroad. The company grew steadily and after another eight years the company M. Joss & Löwenstein moved into its own factory building in Prague-Bubna, which covered an area of 2400 square fathoms . Steam and electricity were to wash fabrication used.

Despite the mechanical assistants, human labor was still necessary, nine tenths of the labor force was female. The wives of the owners supported the training of the female workers until a number of heads were trained.

In 1898, supported by three authorized signatories and a staff of long-time employees, the owners turned their attention to the development of further sales areas. The lion brand , the company's trademark , became known domestically , as well as in Scandinavia and in Italy , Germany , England, Holland , France, Russia , the states of the Balkan Peninsula , as well as Spain and Portugal were among the company's European sales areas. But the lion brand also imported to Africa , both in northern Egypt and in Cape Town . Likewise, Brazil and the other South American states had opened their customs barriers for the lion stamp to a significant import, as it had also found permanent entry into North America despite the high protective tariffs.

The company received awards at the 1873 World Exhibition in Vienna, Sydney 1879 , Melbourne 1880 , the Prague Jubilee Exhibition in 1891 and the World Exhibition in Chicago in 1893 . For their merits and because of the high quality of the products, the owners were appointed imperial and royal purveyors .

Manufacturing process

Around 1900 the factory site consisted of a raw materials store in which the fabrics made of linen and cotton of all kinds to be processed were stacked up to a size of two million meters. The production itself began with the cutting of the laundry. This was done either by hand or with the help of machines and specially made templates . The cut piece was then hand printing with true- provided name and found his way into the Nähsäle . It was prepared by younger employees for treatment with the sewing machine and then sewn inside and outside with the seams necessary for the durability of the piece. The sewing machines, which were set up by the hundreds in large, bright rooms, were driven by a transmission drive. The machine ran by steam power and thus saved the seamstress from stepping on the flyboard . Once the item of laundry was sewn, it went to the inspecting directors. From here it went to the piercing shop , a department in which the laundry item was prepared for machine buttonhole sewing. So it was provided with the buttonholes, partly by hand or by machine, and thus ready for washing. Washing and starching were done using centrifugal machines, in which the item of laundry was either cleaned with water or treated with starch by friction . The hot water vapors developing in the process were drawn off by fans in order to protect the health of the workers and to make it easier to see the work and machines. These fans were installed in all the larger halls of the factory. These were especially important for the workers in the plättsaal . The piece of laundry finished with starch was flattened with iron. Since the beginning of the 1890s, the iron has been heated by gas flames for sanitary reasons . The manufacturing process was finished with the flattening.

Factories

In 1898 the systems consisted of two steam engines ( Hartung-Radanovits system ) with a total of 300 hp . The work rooms were illuminated electrically, the electricity was generated by three dynamo machines. 360 auxiliary machines were used for the various manipulations. which employed 1050 people in the Prague factory. In addition, according to the system of the Prague factory, there were branch factories in Klattau and Neuern on a smaller scale, in which a total of 520 people were employed. The number of employees working outside the factories was around 300 people.

Social

The company took care of the social issues of the workforce. The factory owners set up their own company health insurance fund for the employees , which existed before the legally mandatory introduction. For sick people, for whom, according to the statute at the time, no support was to be provided after 20 weeks of illness, the company set up a fund set up for this purpose, which granted medication and sick pay for another 20 weeks. In addition, there was old-age insurance for the workers, which put 2% of their earnings as savings . The company was able to secure membership of the Böhmische Sparkasse for workers insured in this way .

Individual evidence

- ↑ M. Joss & Löwenstein . In: Presented by the industrialists of Austria under the high protectorate of His K. and K. Highness of the Most Serene Archduke Franz Ferdinand (Hrsg.): Die Groß-Industrie Oesterreichs . Festival ceremony for the glorious fiftieth anniversary of the reign of His Majesty the Emperor Franz Josef I. Volume 4 . Leopold Weiss, Vienna 1898, X. Garment Industry, p. 413-414 .