sewing machine

The sewing machine is used for the mechanical production of a seam .

functionality

Interplay of needle and thread

To produce a seam within a fabric , one or more threads ( sewing thread ) are linked to one another by sewing , the so-called upper thread being pushed through the fabric beforehand with a sewing machine needle . After the sewing needle has pierced through the material to be sewn, a gripper takes over part of the upper thread initially lying on the needle; this must be made accessible to the gripper beforehand. This is usually done by the loop stroke, a needle movement that takes place after the bottom dead center of the needle in the direction of the stitch and loosens the thread from the needle.

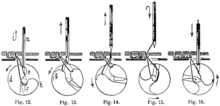

The ensuing entanglement in the lockstitch machine either by passing a bobbin thread winding between the needle and large drawn thread loop, wherein the bobbin thread is unwound, or by Umführen the thread loop around a coil winding. The picture shows the looping of a thread loop of a single vertically rotating hook around a bobbin thread lap to form the lockstitch. Most of the uniformly rotating hook systems built today make two rotations per stitch, but there are also hook systems built with three rotations per stitch. The horizontally rotating gripper systems allow the bobbin to be changed from above. Oscillating hook systems are also often used in inexpensive household sewing machines.

- In chain stitch machines , instead of the bobbin winding, the next needle penetration is used to create the loop.

The picture on the right shows the stitch formation of a single-thread chain stitch, as it is still often used today for button sewing, handle wrappers, point sewing machines, line-up machines, etc. in the sewing industry. If the looper is thread-guiding, it is called a double chain stitch . However, with this type of stitch, the needle thread loop is linked by the looper thread; the looper thread itself is linked by the next penetration of the needle, so that a double link is created. To do this, the needle has to pierce precisely into the thread triangle , which requires that the loop of the previous needle thread and the looper thread are in a specific, stable position in order to enable the linkage. Often several needles and one looper thread are used (lower deck seam), and upper thread layers are also used in combination.

- Overseaming usually have two claws, both of which can be stringy leader. You work around the serging edge, the linkage through the needle takes place on the top of the sewing material, while the linkage of double chainstitch machines takes place on the underside below the throat plate. Fur sewing machines also work around the fabric edges to be sewn. Both machines with only one gripper (single-thread chain stitch) and other gripper systems are used here. Conventional here is the transport of the sewing material by means of driven, horizontally rotating plates.

- The machine-made hand seam sews a short thread that is threaded into the eye of the needle . Two needle-nose pliers, which work above and below the fabric, push and pull the needle alternately through the fabric. The eye of the needle is in the middle of the needle, the two needle ends are pointed.

This seam is also created using a sewing machine with a hook needle. The hook is at the end of the needle near the tip of the needle. So that the hook does not damage the fabric, it is covered by a movable slide while it is piercing through the material. The sewing thread is inserted into the needle hook above the sewing material. To do this, the slide is operated to release the hook. After the hook is subsequently closed by the slider, the sewing thread is cut to the length to be sewn. The hook needle pierces through the sewing material. Now the slider releases the thread for complete transfer to the hook and the thread tongs. The next stitch is a blank stitch. The thread is then put back into the hook of the needle with the thread pliers, so that the following stitch becomes a stitch with sewing thread again (point stitch).

The length of the threads that can be sewn results from the size of the gripper path, which takes over the pulling of the sewing thread through the sewing material after each stitch (less than 1 m).

- The imitation hand seam creates a single-thread chainstitch seam and works with a hook needle and a needle with an eye.

Passive or actively driven needle stops make a significant contribution to stitch security, since when the needle thread is picked up on the hook, it must be guided very close to the sewing needle without touching the needle. Other stitch- forming organs such as tension, thread lever and thread disc are used to control and tension the threads. In double chainstitch machines, spreaders are also used in order to be able to securely chain the looper thread through the needle.

Stitch length and fabric feed

Suitable transport devices for generating a stitch length or stitch sequence are built for each type of sewing material. The lower feeder, which usually works alone in household sewing machines, has the disadvantage that only the lower layer of fabric is driven while the sewing foot brakes the upper layer of fabric. This leads to undesirable shifts in the fabric layer, which can be partially compensated for by skillfully pulling (stretching) the lower fabric layer while sewing. Pfaff is therefore building a household sewing machine with an additional top feed dog, which partially compensates for this error. In overlock machines and overlock machines, two lower feeders, which can be set differently in the path, are often used, whereby the front feeder can take over the pulling (stretching) of the lower layer of fabric. These machines are also used with an additional top conveyor. The additional top conveyor is widespread in industry and is also implemented by means of driven rollers, wheels or belts in or on the sewing foot. If, in addition to the bottom feeder, the sewing needle is also transported after piercing, this is referred to as needle transport . However, the transport effect of the sewing needle to reduce shifts in the position of the fabric is only effective with inelastic sewing material.

In the leather goods sector, triple transport machines are sometimes used. This is where the bottom feed dog and the top feed dog come into play, with the needle also transporting during the stitch formation process. A holding foot is raised during the transport process and holds the sewing material when it is transported empty (alternating transport). If there are insufficient transport organs available, sewing feet can be covered with Teflon; Roller feet are also used. Powered roller feet are also common in the shoe industry. In the past, it was common practice to powder leather goods or oil plastic material if there was insufficient transport. Friction-reducing paper was also partially sewn. This practice is still common today when sewing velvet in the home.

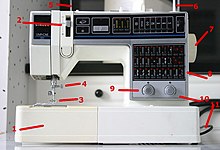

Machine types

The basic form of the sewing machine is the right-hand flatbed sewing machine. Appropriate sewing machine shapes have been developed for special operations, which can be distinguished as follows: flat bed, base, column, free arm and block sewing machine. Left-hand sewing machines were also occasionally built; the arm machine is divided into free-arm, arm-down and arm-up sewing designs. The column machine is available in several column heights and designs as well as with a rotating crank column in various designs.

Sewing machines, buttonhole machines

Automatic sewing machines usually work with tools that are designed for special work processes, such as creating a buttonhole, sewing on buttons or a defined locking mechanism. Knives are often used to couple other operations with the sewing operation. The simultaneous trimming of the seam edges while sewing is widespread. A movable upper knife and a fixed counter knife are usually used here, with long service lives being achieved if one of the two knives is made of hard metal. Buttonhole machines usually cut the sewn buttonholes automatically before or after sewing. But knives are also used for other sewing work because the incision for the seam can be precisely determined. Most industrial sewing machines have built-in automatic thread trimmers. Button sewers can be equipped with automatic button feed. Fully automatic machines that do without operating personnel have only rarely been implemented; Textiles that do not occupy pre-determinable positions are not well suited for automation. However, corresponding semi-automatic machines are used for many special jobs.

Micro sewing machines

In addition to such large sewing machines, there are, on the one hand, very simplified household sewing machines , some of which have been reduced to the size of toys, known as mini sewing machines . They basically have a built-in electric motor and are operated with low voltage, optionally with batteries or AC adapter. But they are too big for luggage (shoe box format). There are also very low-priced so-called hand sewing machines; These are small devices for hand luggage, the approximate size of cigarette packs, and not dissimilar in appearance to staplers. They generally work with a single thread and therefore create a chainstitch seam that is naturally prone to pulling open completely if it is damaged or missing a finish. These hand sewing machines are purely mechanical without a motor drive (they have to be squeezed by hand for each stitch, like a staple pliers) and battery-operated with an electric motor (a common model also has a connection socket for operation with a mains adapter). These hand sewing machines require special machine sewing needles that are smaller than sewing needles for household sewing machines. Among other things, they are particularly suitable for sewing on already installed home textiles (curtains etc.) or for emergency repairs when traveling. The mechanical devices cost less than the electrical ones, are smaller and lighter than the motorized ones, and also cannot fail due to dead batteries, but the motorized ones are more convenient to use. The further development remains to be seen: So far, the mechanics of hand sewing machines have been quite simple; Although they have a material transport, they can only produce simple straight seams. In principle, it should be possible that you can also create some types of utility stitches. Corresponding models are not yet known.

Overlock sewing machine

An overlock sewing machine (short: overlock) is used to sew, overcast and precisely cut fabric in one operation.

Installation of industrial sewing machines

The replacement of the transmission drive by individual electric drive motors on each sewing machine enabled the flexible integration of sewing machines into a wide variety of production processes. Series production for feeding the sewing workstation is carried out using a variety of goods transport devices, including sliding systems or hanging systems. Corresponding workplace designs are often made with appropriate shelves or tables and are specially designed for the corresponding sewing process.

Most industrial sewing machines are assembled with a four-legged iron frame and a table top attached to a transportable sewing unit standing on the floor. The electric drive motor is often located under the table top, and the power is then transmitted via V-belts. Sometimes electric drives are also integrated directly into or on the sewing machine. The floor on which the sewing unit stands dampens the vibrations of the moving parts, even if they are mounted on rubber buffers. Depending on the requirements, other sewing units are also common. Sewing machines for closing bags or sacks are integrated into semi-automatic or fully automatic filling devices; hanging sewing systems are also common here. Hand sewing machines are used to manually close sacks; the integrated drive is supplied with energy via flexible power cables, batteries or compressed air.

Drive types

At the beginning of the development, sewing machines were driven by hand cranks or by pedal by the feet of the sewing person, in the early days of industrialization also by central drive machines via a transmission system . Nowadays done driving a sewing machine usually with a motor , although still sewing machines Cycle are in use and are manufactured. Before electrification, space-saving table sewing machines had a crank handle with a transmission. One turn of the crank corresponded to three stitches.

Electrically powered household sewing machines of the simplest design (starter motor) have an adjustable series resistor, usually in the form of a pedal, of the order of magnitude of 1000 ohms, with which the speed of the motor can be continuously changed. Electronic power regulators are also widespread, whereby the needle position for the last stitch can sometimes be brought into a defined position. With automatic needle down position and needle end position, there is no need to use the handwheel to e.g. As to insert the needle into the fabric, to rotate it around the pierced needle, or to take out the workpiece after the final pass, considering not only the needle in the high position must be, but the thread lever disconnecting the needle thread from the gripper target. This should then be in the highest position (top dead center).

Drive motors of industrial sewing machines are constructed in the simplest design similar to those of household sewing machines. To enable the shafts in the sewing machine to accelerate and brake quickly, three-phase motors with clutch and brake disks are used (clutch motor). Here, after being switched on, the rotor of the electric motor always runs close to the target speed, which is specified by the motor design. The output shaft is equipped with a brake disk and a clutch disk similar to that of motor vehicles. The speed is regulated from zero to a maximum by coupling or braking , a V-belt transmits the power to the handwheel of the sewing machine. In semi-automatic sewing machines with stitch sequences, the clutch and brake were also built into the drive of the sewing machine.

The use of automatic thread trimmers on lockstitch sewing machines requires precise positioning of the handwheel, with defined speeds being observed. Initially, clutch motors with auxiliary drives were used, later clutch motors with self-regulating (electronically operated) clutches and brakes and again later also energy-saving motors without a separate output shaft and without mechanical clutch / brake, which only start / brake when the sewing machine is operated using electricity. These require a large amount of torque in order to achieve short acceleration and braking times. To regulate the sewing machine speed and to determine its angle of rotation, an encoder is always installed in the sewing machine (often on the handwheel), which transmits the necessary signals to the electronics, while the target speed is usually set using a pedal . This can usually be operated on two sides; forward to sew and backward to cut the threads automatically. A second pedal is often used to raise the sewing foot function , whereby the operator always has both hands free for the material to be sewn. Today, different regulations are used depending on the requirements, with sequence sequences and photocell recognition also being used.

The use of microprocessors is widespread in sewing machines. In household machines, they sometimes take on many functions today; the zigzag drive or the overstitch, the backdrop for the stitch length, the raising and lowering of the sewing foot and the embroidery frame are moved by servomotors. Sewing patterns can be called up via control units; high-priced machines have built-in disk drives for calling up embroidery patterns. Interfaces for connection to a PC have also been implemented.

In industrial sewing machines, the electric motors are usually microprocessor-controlled; Inputs and outputs can often be configured very flexibly. Stepper motors are often used in sewing machines today; the drive takes place via a special computer with correspondingly powerful outputs. The resolution is usually a tenth of a millimeter in the direction of each axis. With bartack and buttonhole machines, quick pattern changes can be made or special stitch sequences can be created / changed according to the size of the sewing field. Individual tools can be made and the seam program created for sewing on labels and series. Embroidery machines are also operated as multi-head machines; here the program can be sewn with several sewing machines at the same time. Large sewing fields are also common in quilt and bed manufacture.

Stitch types

For sewing machine uses special sewing machine needles :

Depending on the machine, there are different types of stitches, for. B. only with one thread like a single chain stitch. The lockstitch is mostly used on household sewing machines. But overlock and double chain stitches are also used. According to an international catalog, a distinction is made between six stitch type classes, which are listed in the » DIN 61 400« ISO 4915. A basic distinction is made between elastic and inelastic seams . The seams should always be more elastic than the sewing material in order not to tear when subjected to stress (stretching). So comes with inelastic, z. B. woven fabrics usually use the lockstitch; the seam strength results from the thread thickness, the set tension and the number of stitches. This type of stitch can only be made elastic to a limited extent; Processes such as zigzag sewing or intermediate stitches (utility stitch) increase the amount of sewing thread and thus the elasticity. This widespread type of stitch is afflicted with much disturbance; the bobbin thread space is limited, which leads to frequent bobbin changes; the needle thread is very often pulled through the eye of the needle, especially with short stitch lengths and low thread consumption per stitch, which leads to severe needle thread wear during the sewing process.

Double chain stitch sewing machines are mostly used for knitted fabrics. This stitch type is very elastic due to the loop-shaped stitch formation and the resulting larger thread entry per stitch, especially with short stitch lengths, and is usually better adapted to this type of sewing material than the lockstitch. The significantly lower number of passages of the needle thread through the eye of the needle results in less needle thread wear during the sewing process; the puncture through loose sewing material is also less of a problem. Therefore, not only high-quality, twisted sewing threads are used, but also very often inexpensive multifilament continuous yarns, also textured (bulk yarn), which should be twisted at 150 revolutions per meter.

story

Technical precursors

Like all machines, the sewing machine has had a long development period. In the past, people used bones for sewing. Later the needles were made of sharp bone or horn with an eye . It was not until the 14th century that a needle was made out of iron. For centuries it was the most important tool for making clothing.

Until 1830, people sewed with needles in hand. The tailoring profession was highly respected and the name of a good tailor meant something to the ladies of society. A skilled tailor could make 30 stitches a minute.

It was not until the middle of the 18th century that inventors began to have the sewing needle moved by a machine. The German Charles Frederick Wiesenthal , who lives in England, carried out the first mechanical experiments to produce a seam in 1755. His idea was to have a machine perform the hand sewing movement and use a double-pointed needle with an eye in the middle. This needle shape was later used by Joseph Madersperger , John James Greenough and others. It is still used in the embroidery industry. According to archive documents, however, Wiesenthal never completed a working sewing machine.

Beginnings

The Englishman Thomas Saint built the first working sewing machine for shoemakers in 1790, who patented his design. The machine was made entirely of wood and had a fork needle, pricker and hook needle. She used it to sew a chain stitch . However, the number of stitches was very small, so it did not work particularly quickly.

In Germany , too , there were inventors who wanted to replace the tedious manual sewing work with machine work. Among them was Balthasar Krems from Mayen probably the most significant in the Rhineland (Eifel). Around 1800 he also designed a chainstitch sewing machine that for the first time had a needle with an eye at the tip and a controlled looper hook. An interesting design feature was the Stachelradtransport for the fabric, which by applying a break transmission continuously gradually worked. However, the machine could only be used for the so-called Jacobin hats that Krems produced industrially. His last model, which could sew around 300 to 350 stitches per minute, has been preserved and is in the Eifel Museum in Mayen.

The first sewing machine manufacturer in the world was the French Barthélemy Thimonnier . In 1829/30 he developed his basic sewing machine model Couseuse , patented on July 17, 1830 , which could already execute 100 stitches per minute, followed by other and better models. In the same year Thimonnier went to Paris with his partner Ferrand and founded the Societé Germain Petit et Cie , which on the one hand was to produce these new sewing machines in series and on the other hand also produced uniforms for the French military administration. The company, which had over eighty sewing machines, was successful. Thimonnier only had one problem: he could not cope with his absence from home and family, he left Paris "on the run" in 1831. The manufacturer Germain et Petit continued to work for decades - the often reported destruction of the factory never took place, according to archive documents.

His adventure in Manchester ended in the same way. Thimonnier was supposed to build the newly developed cousobrodeur in series for the Lakeman company , but fled back to Amplepuis to his family after a few months . At the world exhibitions in London and Paris it became clear that Thimonnier had missed the train of time due to his incomprehensible behavior and long hesitation. He died impoverished in Amplepuis on July 5, 1857. Original Thimonnier sewing machines are in the Amplepuis Museum, the Doyen Collection in Lyon and the Paris Museum of Commerce .

From 1807 to 1839 Joseph Madersperger from Kufstein worked on the manufacture and improvement of his sewing machine. This was initially equipped with a double-pointed needle with an eye in the middle, but in the course of development he decided on the eye-pointed needle. His invention to be emphasized was a boat-like device for generating the double stitch. Unfortunately, he did not succeed in convincing the public at the time. He died in the poor house in Vienna in 1850. His simple grave can still be seen in the St. Marx cemetery .

The American Walter Hunt had a similar experience in 1834. He developed the first machine that worked with two threads and was also equipped with a shuttle . However, he failed to get his machine to work. John James Greenough received the first US patent for a sewing machine that could also be used for leather processing on February 21, 1842. However, he was also not granted any economic success.

The development of a fur sewing machine was a particular challenge , as the processing of leather and fur is complicated by the hardness and different material thicknesses. Joseph Priesner's Berlin company began its first attempts in 1870. Two years later he was able to bring the world's first fur sewing machine onto the market. It had the type designation Ia and made a solid, closed seam with two threads, but it was not yet stretchable enough. Priesner presented the Electra I a at the world exhibition in 1873 and was awarded a gold medal.

Industrial manufacture

In 1846 an American named Elias Howe built a sewing machine based on the same principle. This machine did the sewing work for four to six hand seamstresses. It is fair to say that Elias Howe was the inventor of the lockstitch sewing machine. It is still assumed to this day that Howe actually developed the sewing machine. It was in Boston around 1839 when the impoverished mechanic Elias Howe, who was having trouble feeding his wife and three children, heard his boss say to a customer: “Anyone who ever invents a machine that can sew can do one Fortune! ”Howe never let go of this idea. He observed his wife's fingers and first tried to machine their hand movements. The first attempt failed, but he was not discouraged. He fiddled around until he had built a sewing machine that sewed 250 fixed stitches a minute. In a competition against skilled manual seamstresses, the seamstresses sewed 50 stitches per minute, but his machine sewed 300. For lack of money, he sold it to his brother with a patent promise. It was not patented in America, but on December 1, 1846 in London in the name of W. Thomas. Still, he couldn't find anyone who wanted to buy them and produce them in large numbers. He demonstrated his machine to two manufacturers. They shied away from the price of 300 US dollars and also feared threats from the Tailors' Guild. Since he could not achieve anything in America, Howe traveled to England with his family , since he figured he had better chances there.

Two years later he returned to the United States with even less capital ; he earned the ship's passage as a ship's cook. When he arrived, he had a bitter surprise: in the two years that he was away, a certain Isaac Merritt Singer , also a mechanic from Boston, had invented and patented a sewing machine that was now being sold in stores for $ 100. Howe challenged the Singer patent. The process dragged on. The judge eventually concluded that Singer's sewing machine profits had to be shared, and Howe received $ 4,000 in patent fees every week until his death at age 48. Since Howe won the rest of the patent litigation, his invention made him a wealthy man after all.

Successful market launch by the manufacturer Singer

It is thanks to IM Singer & Co. , founded by Isaac Merritt Singer in 1851 , that the first sewing machines based on Howe's idea were factory-made. The company owner made the sewing machine popular and generated corresponding sales. Another invention of this company is selling to pay off : Edward Clark , a partner of Singer, in 1856, designed the hire-purchase plan, the prototype for installment sales. Singer was a failed inventor at the time who couldn't sell a letter carving machine. He therefore worked in Orson Phelps' sewing machine shop, who made Blodgett and Lerow's sewing machines. These machines had the same disadvantage as the Howe sewing machine: They only sewed as far as the sewing rail could reach - about 30 to 40 cm. Singer changed the design with a vertical needle bar, a horizontal drive shaft and a continuous fabric transport. The patent for these changes made it possible for the partners Phelps, Zieber and Singer to set up a workshop. It is well known that Singer also developed into a “marketing genius”. The payments to Howe, however, were based on a component previously patented for Howe that Singer had acquired from Blodgett. All other manufacturers also had to pay taxes to Howe for it.

The partners Grover and Baker in America received the patent No. 7931 for the two-thread chainstitch sewing machine on February 11, 1851. Years before, the cabinet maker Wilson had developed a forward and backward sewing machine, for which he received his first patent in 1850. However, the evaluation was impossible because the double- pointed shuttle used was already protected. Wilson therefore teamed up with Wheeler and designed a rotating gripper with a spool , which was patented in 1851. From this, in turn, the first sewing machine with rotary hook, curved needle and hopper transport was created in 1852. The American technician Walter House later developed the basic invention, the rotating gripper, further.

James Gibbs , a farmer from Virginia, designed a novel chain stitch sewing machine in two years and patented it in 1856. Together with Willcox, he improved the machine and had it manufactured in series. Because it was inexpensive, it found large sales for the time and was hardly changed until almost 1930. In 1887 the Willcox & Gibbs company brought a new sewing machine with three loops with glasses rotating three times per stitch. On April 17, 1873, Eduard Ward received the patent for his gripper arm and plate. In 1885, Techniker House improved the Wilson rotary grapple. In the same year, the Mack brothers developed the standard gripper, a rotating gripper that is moved by two pins that alternately engage in suitable holes in the bottom of the gripper. The rotary gripper from White, which dates from 1900, works in a similar way to the standard gripper from the Mack brothers. It runs in an inclined path and is moved by the alternating engagement of driver pins.

Further development to the household sewing machine

The development of the household sewing machine was hardly influenced by the construction of the first German zigzag sewing machine in 1882 by John Kayser (the English and American machines had been around for a long time). The Kayser sewing machine was too cumbersome and too prone to failure. The zigzag sewing machine did not gain acceptance until after 1930 - the decisive factor was the design of the master mechanic, Handschuh. The seam differs from the seam of the straight stitch machine in that it is more elastic and is used for special jobs.

In 1893 the first hemstitch machine was built by the Gegauf brothers in Switzerland, invented by Fritz Gegauf. A few years later, the new Fritz Gegauf AG sewing machine factory was created , which still builds sewing machines to this day. From 1932 these machines were called BERNINA. From 1946 the Gegauf brothers in Steckborn (Switzerland) built the world's first zigzag free-arm sewing machine. After the Second World War , sewing machines for domestic use with automatic utility and decorative stitches that were controlled with cam disks appeared . By coupling a few cams, hundreds of decorative stitch patterns could be created in a purely mechanical way.

In 1940, the Tavaro SA company in Geneva built the first portable electric free-arm sewing machine based on the patents of Casas, who had already had the first pilot series produced five years earlier. After many very successful models, the company is now also closed.

From 1986 the first Bernina sewing machine was electronically controlled by stepper motors. This means that the utility or decor stitches no longer have to be set by hand. The sewing machine turned into a computer, which reached a high point in the sewing industry with the Bernina 830 . The Bernina 830 is a household sewing machine with an attachable embroidery module and integrated Windows CE . It can be connected to the computer and to the Internet. In 2005, the Bernina aurora model with a stitch regulator came onto the market as a novelty. This regulates the constant stitch length when quilting .

Development of the household sewing machine

Household sewing machines were very similar to industrial sewing machines in the early days, but over time they developed in completely different directions. At first only forward sewing (the sewing foot was lifted slightly to sew backwards and the material moved by hand) the stitch changer for backwards sewing and the zigzag setting for ZZ sewing also prevailed on household sewing machines. Then the specifications separated; While the industrial sewing machines were mainly geared to the special needs of the textile and leather goods industry and built special machines, in the household sewing machine area the overlock machine with edge trimmer for overcasting and sewing fabric edges and the blind stitch or pricking machine for invisible (not pierced) sewing have proven to be noteworthy household sewing machines. Special table machine developed. In contrast, the standard household sewing machine was often provided with the functions or features of special industrial machines. Household sewing machines with devices for the simple creation of a buttonhole up to semi-automatic buttonhole were created; Ornamental patterns developed into utility stitch , with which z. B. elastic fabrics or skirt hems were easy to edit. Embroidery, darning , free arm , being able to sew with two needles; a device for easier threading of the needle thread into the needle eye; winding the bobbin thread through the sewing needle without removing the bobbin, just to name a few additional functions. Lighter cast aluminum housings soon replaced the gray cast iron housing , which reduced weight and made the space-saving suitcase sewing machine (table sewing machine) easier to accept.

While the mechanical parts of the extended functions were initially built into the cast body through ever larger assembly openings, an open block variant was then used in the generations of electronic machines (computers, touch keys) in which the additional and drive elements are attached on all sides. In order to maintain the appearance of a typical sewing machine, the machine is covered with housing shells (design). These machines usually no longer have any oil points, as they are designed in such a way that the factory lubrication is permanent.

In general, efforts were made to reduce manufacturing costs at an early stage. As early as the early 1950s, when household sewing machines became increasingly complicated, the first large sewing machine manufacturers replaced metal bevel gears and other parts with plastic, or the design was switched to other systems such as drive belts or toothed belts; inevitable movements of the needle bar rocker were partially replaced by spring return; Metal parts of the gripper have been partially replaced by jam-free plastic, and inexpensive gripper systems have been developed. This often resulted in changes in the longevity of the machines or machine parts, the stitch precision and the stitch security decreased, especially if the stability of the stitch forming organs and precisely adjustable needle stops were dispensed with and the vertical movement of the bottom feed dog takes place at unfavorable times.

Structural crisis in the sewing machine industry

Over two hundred companies in Germany were involved in the construction of sewing machines. Names like Müller, Naumann, Seidel, Opel, Koehler, Adler and Phönix were among them. The German sewing machine industry had to survive several crises in the last century. First of all, there were the two world wars, which resulted in almost all sewing machine factories having to switch their production to war-essential items. The loss of all foreign trade was difficult to make up for after the wars. Around 1948, well-known companies that were not allowed to continue their traditional production switched to sewing machines - Messerschmitt, Zündapp and Elac were among them. After just a few years, the market became tight, on the one hand due to a larger number of manufacturers, and on the other hand, ready-made clothing became cheaper and cheaper, so that it was no longer worthwhile to sew your clothes and underwear yourself. In addition, the first inexpensive imports of sewing machines from the Far East were offered. The resulting price war led to amalgamations of German companies - Apha (= anchor, phoenix, eagle) - or to joint ventures with Japanese - Adler-Toyomenka and the like - and ended in the 1970s with almost all German companies ceasing to produce. Only Pfaff initially survived, but ended later, as did Singer and Elna. Pfaff household sewing machines are now being built by Viking-Husqvarna in Sweden (which also took the manufacturer Meister off the market); Bernina in Switzerland is another large household sewing machine manufacturer. Singer has also changed a lot. The actual Singer company turned to space technology years ago and handed over sewing machine production to a licensed company.

Some other sewing machine manufacturers were able to keep their production because they were sold under different brand names through sales partners. For example, Veritas (VEB sewing machine works Wittenberge) delivered products to the department and mail order houses Quelle and Neckermann under the brand name Ideal and Brillant until the late 1980s . The Italian vehicle parts manufacturer Borletti also sold its sewing machine division for Neckermann under the Brillant label until the 1970s. Borletti stopped its sewing machine production in the early 1970s. The Italian manufacturer Necchi still supplies Aldi under the Medion label.

The VERITAS sewing machine plant in Wittenberge , built in 1903 by the American Singer Company NY , reached annual production figures of over 400,000 in the 1980s. After the reunification of Germany, the German Treuhandanstalt liquidated the company.

With the closure of the Veritas sewing machine plant in Wittenberge in 1991 and the sale of Pfaff's household sewing machine division with a production facility in Karlsruhe-Durlach in 1999, what was once an important branch of industry in Germany came to an end - the production of household sewing machines. With the sale of Pfaff Industrial to the Chinese SGSB Group Co., Ltd. on March 6, 2013 . (including the owner of Dürkopp Adler ) the last German manufacturer lost its independence.

Old sewing machines are still available in many households today and are offered as antiques at flea markets or in junk shops , for example . In spite of their decorative appearance and their age of sometimes more than 100 years, the material value of the models produced in large numbers by the major manufacturers is quite low. On the other hand, because of their robustness, old industrial machines designed for this application are still in demand for processing heavy materials (e.g. leather).

German sewing machine manufacturer

The first American sewing machines came to Europe in the 1850s and were immediately reproduced. Carl Beermann in Berlin in 1849, Christian Mansfeld in Leipzig in 1853 and F. Böcke in Berlin in 1854 were among the first German manufacturers who, however, relatively quickly shifted their business to other areas or soon gave up sewing machine production for other reasons. The first German manufacturer was Clemens Müller in Dresden in 1855. Around 100 other companies followed him. American companies therefore always had major problems on the German market - with the exception of Georg Neidlinger's Singer company in Hamburg.

One of the first producers was Joseph Wertheim , who had worked as an apprentice in the Singer sewing machine factory in America from 1854 to 1858 and, after his return to Germany, presented the first sewing machine in Frankfurt am Main in 1861 . From 1862 he acted as general representative of Wheeler & Wilson for southern Germany, from 1863 he manufactured sewing machines in-house and founded the German sewing machine factory , in which in 1865 the 1,000th machine was manufactured in-house. In a factory in Frankfurt-Bornheim that was newly opened in 1868, up to 600 workers produced a total of 1,500,000 sewing machines in the years up to 1920. In 1932, production was relocated from Germany to the Rapida SA branch in Barcelona , which had been founded in 1870 , where sewing machines were still produced under the Wertheim name until 1975 .

One of the other companies was the Bernhard Stoewer machine factory in Stettin. He began manufacturing sewing machines using the Wheeler & Wilson system in 1862. In 1864, Bernhard Stoewer also took over the system from Grover & Parker, and by 1865 employed eleven workers and four apprentices in his small factory. In 1872 the company was renamed Bernh's sewing machine factory and iron foundry. Stoewer, Szczecin . The number of employees rose to 250 due to large orders from Scandinavia (referred to as Victoria according to the Singer system ) and Russia, the number of employees rose to 400. In 1907, Stower produced 75,708 sewing machines; 1920 left the 1,500,000. Sewing machine at the Stoewer factory in Stettin. In 1929 only 30,000 sewing machines were manufactured, in 1931 the liquidation had to be decided. The Adolf Koch AG in Saalfeld took over the machines, devices and brands and distribution rights.

Georg Michael Pfaff from Kaiserslautern is also one of the first successful producers . He was a brass instrument maker and, also in 1862, came from repairing sewing machines to building his own sewing machines, initially according to the Howe system, later Singer. The Seidel & Naumann company has existed in Dresden since 1868 . Leopold Oskar Dietrich, Hermann Köhler and Gustav Winselmann founded a workshop for the construction of sewing machines, the Vesta sewing machine works, in Altenburg (Thuringia) in 1871 . In 1879, Max Carl Gritzner from Karlsruhe designed the double rotating gripper without glasses. In addition to this gripper, his machine had a bobbin case fan, a rotating thread feeder and a controlled thread tension. However, like many inventors, Gritzner fared; his idea only became popular much later when the Americans took over his invention.

Furthermore, the parallelism of the development of the sewing machine and the bicycle is striking, although both industrial products do not initially have much in common. However, both served the same sales market at the same time, and both required precisely manufactured components such as bearings and threaded parts in the same quantities. For this reason, many dealers still sell both bicycles and sewing machines today. The concentration of the German sewing machine manufacturers together with the bicycle industry in a few locations such as Bielefeld is also due to this cause. The same goes for the typewriter . It is not uncommon for all three products to come from the same company.

literature

- Reinhard Bäckmann: Sewing - needle - sewing machine. Origins of sewing technology in the age of the first industrial revolution. Schneider, Hohengehren 1991, ISBN 3-87116-554-9 .

- Otto Landgraf: Oldtimer sewing machine. Landgraf, Dittelbrunn 1987, ISBN 3-926879-06-8 ; German edition: Vintage sewing machines .

- Peter Wilhelm: Old sewing machines. Names, dates, facts. Mecke, Duderstadt 2002, ISBN 3-932752-87-2 .

- Peter Wilhelm: Old German sewing machines. A manual for collectors and sewing machine enthusiasts. Mecke, Duderstadt 1987, ISBN 3-923453-23-X .

- Friedrich Georg Wieck : From the commercial world: The sewing machine . In: The Gazebo . Volume 44, 1853, pp. 478-480 ( full text [ Wikisource ]).

- The story of a house friend . In: The Gazebo . Issue 31, 1867, pp. 492-496 ( full text [ Wikisource ]).

Web links

- Literature on the subject of sewing machines in the catalog of the German National Library

- Biography of Isaac Merritt Singer

- First US patent for a sewing machine for John James Greenough. google.com (english)

- Mey Brothers Sewing Machine Museum (Albrecht Mey Collection Foundation)

- naehmaschine-antik.de

- naehmaschinenverzeichnis.de

- Sewing machine works Wittenberge - naehmaschinenwerk.de

- schlingenfaenger.de - Homepage of the collector friends of historical sewing machines, NM systems

- Video on how a sewing machine works. youtube, after broadcast with the mouse

Individual evidence

- ↑ www.youtube.com: KPCB mini sewing machine . Sample video, April 19, 2019. Last accessed August 23, 2019.

- ↑ www.youtube.com: Handy Stitch Sewing Machine - Product Demonstration . Sample video, September 28, 2017. Last accessed August 26, 2019.

- ↑ Needles for hand sewing machines . Product example needles for hand sewing machines. Last accessed August 28, 2019.

- ↑ a b The invention of the sewing machine , in: Berliner Volkszeitung , August 19, 1905.

- ^ Franz Maria Feldhaus: Technology: sewing machine . (PDF; 2.1 MB) Column 737 ff .; Retrieved February 20, 2010.

- ^ Walter Fellmann: The Leipziger Brühl . Fachbuchverlag, Leipzig 1989, ISBN 3-343-00506-1 , p. 109 ff.