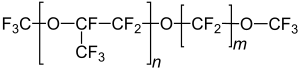

Perfluoropolyether

| Structural formula | |||||||

|---|---|---|---|---|---|---|---|

|

|||||||

| General | |||||||

| Surname | Perfluoropolyether | ||||||

| other names |

PFPE |

||||||

| CAS number |

|

||||||

| Brief description |

clear, colorless, odorless liquid, slightly oily |

||||||

| properties | |||||||

| Physical state |

liquid to pasty |

||||||

| density |

1.83 g cm −3 |

||||||

| solubility |

insoluble in water |

||||||

| safety instructions | |||||||

|

|||||||

| Toxicological data | |||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||

Perfluoropolyethers ( PFPE ) are a group of plastics that are usually liquid to pasty at room temperature and belong to the fluoropolymers , which consist of fluorine , carbon and oxygen .

presentation

Perfluoropolyethers can be prepared by reacting a metal halide with a perfluoric acid halide, a C2- to C4-substituted ethyl epoxide, a C3 + - fluoroketone or combinations of two or more thereof, subsequent reaction of the intermediate product with hexafluoropropylene oxide or tetrafluorooxetane , subsequent esterification, reduction of the ester to its corresponding alcohol and converting it to a salt with a base, reacting it with a C3 + olefin and fluorinating the fluoropolyether.

properties

The chemical bond of PFPE is very stable and the plastic is very inert. The covalent carbon-fluorine bond in PFPE has a high bond energy of 448 kJ / mol.

Applications

Perfluoropolyethers are very inert and can be used as lubricants in pumps which, in the semiconductor industry, convey chemically aggressive etching gases or, due to the low vapor pressure, in high vacuum pumps . The vapor pressure at 20 ° C is 0.013 hPa.

Further applications are in the field of electronics manufacturing for soldering printed circuit boards using vapor phase soldering . PFPE serves as a chemically inert heat transfer medium , which also serves as a protective gas during the soldering process and whose boiling point is matched to the required soldering temperature. The boiling point can be selected in a range from 140 to 290 ° C by specific selection. The soldering process is made possible by the released heat of condensation , which occurs during the transition from the gaseous to the liquid state of perfluoropolyether.

Depending on the area of application, various types of perfluoropolyethers are commercially available under brand names such as Krytox from Chemours (formerly DuPont ) or as Fomblin and Galden from Solvay .

Individual evidence

- ↑ a b c d e f g Product information Galden LS / HS at solvay.com, accessed on July 30, 2017.

- ↑ a b Data sheet Fomblin YR-1800 at AlfaAesar, accessed on July 30, 2017 ( PDF )(JavaScript required) .

- ↑ Google.com: Patent DE60125366T2 - Perfluoropolyethers and process for their production - Google patent search , accessed on January 24, 2017.

- ↑ Perfluoropolyether. Solvay Solexis, accessed October 30, 2018 .