Trans-Alaska Pipeline

The Trans-Alaska-Pipeline ( TAP ) is an oil pipeline in Alaska / USA . It runs 1,287 km from Prudhoe Bay in the north to the ice-free port of Valdez on Prince William Sound in the south.

history

In 1968, petroleum was discovered in Prudhoe Bay . A pipeline was seen as the only feasible solution to transport the oil to the nearest ice-free port in Valdez, 1280 km away . It was the first hot pipeline with 70 to 80 degrees Celsius (the Alaskan oil has a high wax content and therefore could not be cooled). The oil companies with production rights joined the consortium of the Alyeska Pipeline Service Company to design, build and operate the pipeline. Richard Nixon approved the construction of the pipeline by signing the Trans-Alaska Pipeline Authorization Act on November 16, 1973.

The pipeline, which is 1.22 m in diameter, was built between March 27, 1975 and May 31, 1977 for a total of 8 billion US dollars. The tube was built in six construction phases by five different contractors who together employed 21,000 people in the peak phase of construction. 31 of them died in accidents during the construction phase. A hovercraft was specially built for the Yukon River , the Hoverbarge , with a loading capacity of 160 tons. The vehicle was used 8,000 times to transport the pipes alone.

The 799 miles (approximately 1,285 kilometers) that had to be covered presented some particular challenges. In addition to the harsh environment, this included the need to cross three mountain ranges and countless rivers and streams. Also, Alaska's permafrost forced designers to build the pipeline on stilts for almost half the length. This became necessary because otherwise the pipeline would have melted the ice due to the temperature difference between the oil and the surrounding area and would have sunk into it.

For this reason, the surroundings were observed for five years and geological samples were taken before the work began. During the construction of the pipeline, geologists were often called in to examine previously undiscovered areas that had been affected by excavations.

The pipeline was designed with earthquakes in mind, but is at risk from deliberate attacks and possibly also from forest fires .

On June 20, 1977, oil flowed through the pipeline for the first time. Since then, over 13 billion barrels (2.1 billion m³) have flowed through, with a peak of 2.1 million barrels (330,000 m³) per day in 1988. More than 16,000 tankers at the marine terminal in Valdez have been filled with the oil. The terminal offers berths for four ships at the same time and cost 1.4 billion US dollars. The first loaded tanker, the ARCO Juneau, left the terminal on August 1, 1977. The construction project won the 1979 Outstanding Civil Engineering Achievement Award from the American Society of Civil Engineers (ASCE).

The future and durability of the pipeline after a fictional disappearance of mankind is shown in episode 7 of the 2nd season of the documentary fiction series Future Without People (“Waves des death”, USA 2010).

Claims

The pipeline was damaged several times.

In February 1978, 16,000 barrels (2500 m³) of crude oil was lost in a deliberate explosion near Steele Creek , Fairbanks . However, no culprit could be found.

Between 1978 and 1994 there were an annual average of 30 to 40 leaks, with the last four years accounting for the lion's share with a total of 164 leaks. However, none of these damages were really serious. From 1995 the operators succeeded in reducing the number of leaks to such an extent that only three barrels of crude oil were lost between 1997 and 2000.

Although the pipeline itself is bulletproof, on October 4, 2001, a drunken hunter managed to shoot a hole in a weld , which lost 6,000 barrels (950 m³). The hunter was later arrested.

Further damage occurred in 2003 when an excavator operator trying to remove trees accidentally grabbed the pipeline and broke it in two. About 7000 barrels (1100 m³) were lost.

March 2006: Leak in the pipeline

On March 2, 2006, a BP Exploration (Alaska) employee discovered a major oil leak in western Prudhoe Bay. At least 267,000 gallons (approximately 1010.7 cubic meters) of oil leaked, making it the largest oil leak in northern Alaska to date.

August 2006: Temporary closure of the pipeline

The March 2006 accident prompted the United States Department of Transportation to require BP to inspect the pipes for corrosion with a so-called diagnostic pig. This inspection robot can run through the inside of the lines and check the wall thickness of the lines. In the process, BP discovered some serious corrosion damage.

As a result, BP announced on August 6, 2006 that approximately 16 miles of the pipeline in the bay would need to be replaced. On this route, the wall thickness was lost by up to 80% from the original 10 mm due to corrosion. BP was surprised to find such severe corrosion. However, the company emphasized that regular corrosion controls had been carried out in coordination with the authorities. The lines were regularly flushed with chemical agents for corrosion protection and regularly examined by ultrasound . At BP it was assumed that these methods were suitable and sufficient. As it has now turned out, this is not the case.

The unexpectedly strong corrosion was caused by electrical voltages of up to 12 volts, which were induced in the metal tube by solar storms and associated geomagnetic storms. The company then decided to close it temporarily.

On August 11th, BP announced that production would continue in the western portion of the Prudhoe Bay oil field. This decision is based on new research results and was made in consultation with the state authorities. After BP resumed production in the eastern part of the oil field at the end of September with approval from the US Department of Transportation, the daily output is now (at the end of October 2006) back at more than 400,000 barrels. This is equivalent to production prior to August 6, 2006. Experts estimate the tax shortfall for the State of Alaska to be approximately US $ 6.4 million per day.

May 2010: claim

A new accident occurred in May 2010 that released over 100,000 gallons (approximately 380 m³) of oil.

January 2011: claim

The pipeline had to reduce capacity on January 8, 2011 due to a leak, and by January 17, after the repair work, full capacity was reached again.

technology

| Technical specifications | |

|---|---|

| construction time |

April 29, 1974 to June 20, 1977 |

| Deaths |

32 during construction 10 since construction |

| length | 1,287 km |

| Pipe diameter | outside: 1.22 m |

| Wall thickness |

1.17 cm (over 750 km) 1.43 cm (over 538 km) |

| Thickness d. Pipe insulation | 9.5 cm |

| Support points | 78,000 |

| Filling volume |

9,059,057 barrels = 1,440 million l |

| Flow rate |

759,081 barrels / day = 120 million l / day = 83,800 l / min. |

| Flow rate | 6 km / h |

| Flow time | 11.9 days |

| Maximum pressure | 81.4 bar |

| Temp. Of the crude oil |

44 ° C (feed) 14 ° C (outlet) |

| Main valves | 178 |

| Fuel consumption of the systems |

794,900 l / day |

| Pig intervals | Cleaning: every 7-14 days Examination: every 3 years |

| The highest point | 1,444 m above sea level NN |

| pitch |

Max. 145 ‰ ( Thompson Pass ) |

| Pipeline bridges | 13 |

| River crossings |

34 large ~ 500 small |

| Wildlife crossing points | Overpass: 554 Underpass: 23 of them . 2 chilled |

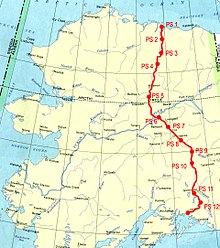

There are eleven pumping stations along the pipeline, each with four pumps. Each electric pump is powered by diesel or natural gas generators. Originally twelve pumping stations were planned, but pumping station 12 was never built. This also explains the gap in the numbering of the stations. Normally only about seven of the stations are operated at the same time, which should be further reduced by the planned use of newer high-performance pumps.

In the areas with permafrost susceptible to dew, where the pipeline had to be laid underground because of traffic junctions or avalanche slopes , it was laid in a canal. Insulation inhibits the transfer of heat from the warm pipeline pipe to the ground, cooling systems pump cold saline solution through 15 cm thick pipes that lie in the ground parallel to the buried pipeline in order to keep the ground nearby frozen. Depending on the sensitivity of the soil, isolated, but uncooled or even conventional channels were built in other places.

In some elevated parts of the pipeline, the supports, which would otherwise conduct too much heat from the pipe into the ground, are passively cooled. Heat pipes , filled with the appropriate amount of dry ammonia , cool the legs of the supports close to the ground through evaporation in the pipe and are themselves cooled by radiators , which give off heat to the ambient air and the refrigerant condenses inside.

The oil, which comes out of the ground at a temperature of around 80 ° C, is fed into the pipeline at a temperature of over 50 ° C. Without the heat pipes mentioned, so much heat would be conducted from the oil through the steel supports of the pipeline into the ground that the permafrost would be melted locally. This would cause the pipeline to sink and run the risk of breaking or rupturing.

The ammonia contained in the heat pipes absorbs the heat and evaporates at the bottom of the pillars and then rises to the tips of the radiators, where the cooler air there causes condensation . The ammonia then flows back to the ground, where it evaporates again and the cycle starts all over again.

Since the boiling temperature of ammonia at normal pressure of -33 ° C is significantly lower than the maximum permissible temperature of the permafrost and on the other hand, ammonia only reaches about 8.5 bar vapor pressure at +20 ° C, ammonia is suitable as a refrigerant and the cooling works here as a whole Year.

Engineers and maintenance staff consider this simple, self-cooling system to be the greatest innovation developed with the pipeline.

In order to give the pipeline room to maneuver in the event of thermal changes in length or earthquakes, it runs in a more or less pronounced zigzag track. The support struts of the pipeline have special “shoes” to enable these movements as well. Crumple zones are also provided there to compensate for sudden impacts from earthquakes, avalanches or vehicles.

maintenance

The pipeline is inspected several times a day, which is mostly done from the air. Thanks to the convenient location of the inspection bases, the entire pipeline can be inspected in just two hours. However, the inspections usually take longer to ensure a certain thoroughness of the investigation.

Another method are special measuring devices , so-called pigs , which are sent through the line at regular intervals. Some of them are used to remove paraffin deposits inside the pipeline, while others have complex electronics that can determine precise readings about its composition as it flows in the crude oil.

Web links

Individual evidence

- ^ G. Thorwarth: Pipeline through Alaska. In: Josef Brecht (Ed.): Friedrich-Koenig-Gymnasium Würzburg. Annual report 1976/77. Würzburg 1977, p. 67.

- ↑ American Experience. The Alaska Pipeline. Timeline | PBS

- ↑ Large Commercial Hovercraft Contemporary Documentation (video recording)

- ↑ Solar storms electrify the pipeline. In: Spiegel online August 10, 2006. Retrieved August 29, 2010.

- ↑ Smart Pig: BP's OTHER Spill. (on-line)

- ↑ Pump Station 1 Booster Pump Piping Incident ( Memento of the original from July 21, 2011 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , alaska.gov on January 17, 2011

- ↑ the facts, trans alaska pipeline system ( Memento of the original of July 10, 2007 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Brochure from the Alyeska pipeline Service Company

- ↑ Note. The high-altitude section of the Lhasa Railway in China and Tibet, built in 2005, was also built in sections on permafrost and the ground on the railway line, the gravel of which absorbs solar heat, was cooled by ammonia heat pipes in the form of steel pipes driven into the ground.

Coordinates: 64 ° 9 ′ 26 " N , 145 ° 50 ′ 56" W.