Cylinder head

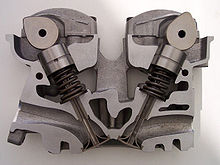

The cylinder head closes off the combustion chamber of an internal combustion engine at the top. The term “top” is to be understood from the point of view of the oscillating piston. In the case of boxer engines and engines that are installed in a suspended manner (such as aircraft engines), one speaks of a cylinder head, although this is not spatially above. In all modern four-stroke engines it houses the inlet and outlet channels and the valve control for the gas exchange processes , oil channels for the lubrication of the valve train and in water-cooled engines also coolant channels, in gasoline engines the spark plugs , in gasoline direct injection also the injection valves or in diesel engines the injection nozzles and the Glow plugs . Due to the complicated production, the cylinder head is one of the most complex and expensive parts of an engine, along with the engine block .

In valveless two-stroke and side-controlled four-stroke engines, the upper end of the cylinder, which does not contain any control elements, is often called the cylinder cover . The cylinder head cover , on the other hand, better and more commonly called valve cover , sits on the cylinder head of an internal combustion engine. It forms the removable cover of the housing for the valve control and prevents the lubricating oil from leaking out and dirt from entering. In some very old engines, this housing and thus the cover are missing, so that the valve springs and possibly the valve actuation can be seen in operation.

Typology

Cylinder heads can be classified according to the following characteristics:

- Otto engines (with spark plugs) or diesel engines (without spark plugs, instead injection nozzles).

- Air cooling (ribbed) or water cooling (double-walled)

- Bottom or overhead camshaft .

- One or two camshafts.

- Type of valve actuation: rocker arms , rocker arm , tappet

- Cross-flow cylinder head or counter- flow cylinder head (reverse flow flushing ). Some engine types do not quite fit into this scheme: the inlet is on top and the outlet on the side, for example in the engine of the BMW 328 , at Borgward , the engine of the Opel Kadett A and twelve-cylinder engines from Lamborghini.

Components

Depending on the combination of the above criteria, a cylinder head contains:

- Inlet valves: Either air (in diesel engines) or the air-fuel mixture generated by the carburetor or the injection system is sucked in through them . As this sucked gas is cold (maximum motor temperature in naturally aspirated or charge air temperature in supercharged engines ), the intake valves is not so subject to high temperatures, such as the exhaust valves.

- Exhaust valves: through these the exhaust gas escapes into the exhaust pipe (exhaust manifold ), also known colloquially as the exhaust . Exhaust valves are therefore exposed to high temperatures.

- Camshaft (s): In modern engines, the camshafts are overhead and sit in the cylinder head. For example, they are driven by the crankshaft with a timing chain . In four-stroke engines, the speed of the camshafts is half that of the crankshaft, as it requires two crankshaft revolutions for each work cycle. A distinction is made between engines with one or two overhead camshafts. ( OHC = overhead camshaft or DOHC = double overhead camshaft). Open the camshafts the valves over ram , towing or rocker arms , they are usually closed by the valve springs.

- Spark plugs: In four-stroke petrol engines, they emit an ignition spark every second crankshaft revolution to initiate combustion , in two-stroke engines with every crankshaft revolution. Diesel engines are self- igniting and have no spark plugs, but glow plugs as a cold start aid.

- Position of the injection nozzles: In diesel direct injection engines, they inject directly into the combustion chamber at high pressure. In prechamber or swirl chamber diesel engines, they inject into the prechamber; the injection pressure can be lower.

- Petrol injection valves: some are permanently mounted on the cylinder head (often with individual nozzles for each cylinder, "multi-point"), but sometimes also on the intake manifold in front of the cylinder head (with "single-point" injections). In conventional gasoline injection engines, they are located in the cool intake pipe area, in the cylinder head or in the manifold in front of it, and are separated from the combustion chamber by the intake valves. With the newer direct-injection petrol engines, however, they sit in the cylinder head, inject directly into the combustion chamber, where they are exposed to higher temperatures and the risk of coking.

- Inlet and outlet channels : For the gas exchange , i.e. pushing the exhaust gas out of the cylinder and filling the cylinder with fresh gas, channels from the outside lead to the valves through which the gases are directed. With reverse flow purging, the inlet and outlet ports are on the same side of the cylinder head, with cross-flow purging on the opposite sides of the cylinder head. The intake ducts are seldom led upwards. They open next to the cylinder cover or, in the case of opposing valves, between the cylinder covers. If the intake pipe is integrated into the cylinder head, the carburetor can be placed directly on the cylinder cover.

Design features

During the combustion process in a cylinder, the same pressure acts on the cylinder head as on the piston . The cylinder head is therefore exposed to very high forces which push it outwards. For this reason, it is often not screwed to the cylinder but directly to the crankshaft housing, with long tie rods or studs that are passed through the engine block through correspondingly long bores. The pre-tensioning force generated by tightening the screw connection has an elastically resilient effect on the long bolts. As a result, the engine block in between is reliably clamped with the seals and the engine remains tight.

The expansion screws are stretched by tightening them as intended and may only be used once. It is therefore very important that a torque wrench is used during assembly so that the tightening torque specified by the structural design and the assembly preload force of this highly stressed screw connection are observed. It is also necessary to observe the specified procedure with regard to the screwing sequence, torque levels and any obligation to check after the time has elapsed.

The moving parts are included in the oil circuit in all modern engines. The lubricating oil is usually fed through a cylinder channel and the cylinder head gasket to the cylinder head, in rare cases and with old engine types through a separate screwed oil line. A simple, thin-walled cylinder head cover with a rubber or cork seal is sufficient to protect against the escape of pressureless spray oil at the cylinder head .

When the camshaft is located below, the rocker arms of the valves are generally connected to the camshaft located outside the cylinder head via tappets and push rods , which run parallel to the cylinders and transmit an axial movement. Overhead camshafts are driven either by a timing chain or by a toothed belt. Spur gear cascades or shafts running longitudinally on the cylinder with bevel gear drives , so-called ' vertical shafts ', are used less frequently .

There are also very simple cylinder heads in four-stroke engines: in engines with valves on the side ( SV arrangement, "side valves "). These cylinder heads are similar in their flat design to two-stroke heads, as the valve arrangement is part of the cylinder and not the cylinder head. SV motors have long since ceased to be state of the art, even if they are still being built in isolated cases ( Russia , People's Republic of China ).

Cooling takes place via longitudinal or transverse cooling water. With the cross flow, the cooling medium flows from the outlet to the inlet side or vice versa; in the case of longitudinal flow, essentially from the rear in the longitudinal direction of the crankshaft to the front. Cross flow is more advantageous because the individual cylinders are cooled almost equally well and the pressure loss is lower, so the water pump needs less drive power.

The cylinder heads of ship engines are often surrounded by a walk-in gallery so that they can work comfortably, and they are equipped with pressure and temperature sensors that integrate the cylinder heads into the information system with which the engine is remotely monitored and controlled from the bridge or the steering position .

Adjacent parts

The cylinder head is closed at the top with the valve cover (cylinder head cover ). It protects the upper actuating elements of the valve train and prevents the lubricating oil from escaping. In between is the valve cover gasket .

The engine block or cylinder block follows down if the crankcase is a separate component. In between is the cylinder head gasket . In the case of sack cylinders , the cylinder and cylinder head are combined into one component, the head gasket is not required.

Typical work on the cylinder head

- Check the spark plugs

- Adjust valve clearance : Either with appropriate adjusting screws or with ground washers of the appropriate thickness ("shims") (now often unnecessary due to hydraulic valve lifters)

- Grind in valves to restore sufficient compression (rarely necessary, only if the engine is worn or a single valve is defective)

- Renew the cylinder head gasket

- Renewing the toothed belt / timing chain and tensioning device ( chain tensioner ) - for toothed belts: tensioning roller (s)

- Compression test : Instead of the spark plug, a pressure measuring device is used. This allows the general condition of the engine to be assessed; to what extent valves, cylinders, pistons and piston rings are worn and an overhaul is pending. What is primarily important is not the absolute level of compression, but rather an approximately equal value on all cylinders. A compression test is useful when buying a used vehicle with a high mileage.

- As part of an engine repair : reaming or honing of the valve guides, replacement of the valve springs , drilling of the camshaft bearings, flat grinding of the sealing surfaces.

gallery

Cylinder cover on a Piaggio-Ciao -ofa, with spark plug connector

Cylinder cover with decompression valve on the engine of an NSU Quickly

literature

- Richard van Basshuysen, Fred Schäfer: Handbook Internal Combustion Engine Basics, Components, Systems, Perspectives. 3. Edition. Friedrich Vieweg & Sohn Verlag / GWV Fachverlage GmbH, Wiesbaden 2005, ISBN 3-528-23933-6 .

- Wilfried Staudt: Handbook Vehicle Technology Volume 2. 1st edition. Bildungsverlag EINS, Troisdorf 2005, ISBN 3-427-04522-6 .

- Max Bohner, Richard Fischer, Rolf Gscheidle: Expertise in automotive technology. 27th edition, Verlag Europa-Lehrmittel, Haan-Gruiten 2001, ISBN 3-8085-2067-1 .

- Peter A. Wellers, Hermann Strobel, Erich Auch-Schwelk: Vehicle technology expertise. 5th edition. Holland + Josenhans Verlag, Stuttgart 1997, ISBN 3-7782-3520-6 .

Web links

Individual evidence

- ↑ Quality and test regulations for engine repairs (PDF; 616 kB).