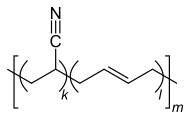

Acrylonitrile butadiene rubber

| Structural formula | |||||||

|---|---|---|---|---|---|---|---|

|

|||||||

| General | |||||||

| Surname | Acrylonitrile butadiene rubber | ||||||

| CAS number | 9003-18-3 | ||||||

| properties | |||||||

| Physical state |

firmly |

||||||

| safety instructions | |||||||

|

|||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||

Acrylonitrile-butadiene rubber , or nitrile rubber for short , abbreviations AB and NBR ( nitrile butadiene rubber ), is a copolymer of acrylonitrile and 1,3-butadiene and is one of the synthetic rubbers . Vulcanized rubber has a high resistance to mineral oils , fats and hydrocarbons . The material is z. B. under the brand names Perbunan N (formerly Buna N ) or Europrene N marketed. There are also other brands of AB rubbers.

history

Nitrile rubber was developed around 1930 at IG Farben by Eduard Tschunkur , Erich Konrad and Helmut Kleiner .

properties

The vulcanizates made from nitrile rubber have high resistance to oils , greases and hydrocarbons , good aging behavior and low abrasion. The acrylonitrile content in NBR can be between 18 and 50 percent and influences the following properties:

- Swelling resistance

- elasticity

- Cold flexibility

- Gas permeability

- Compression set

For example, an NBR material with 18 percent acrylonitrile shows very good low-temperature flexibility down to approx. −38 ° C with moderate oil and fuel resistance, whereas an NBR material with 50 percent acrylonitrile shows low temperature flexibility only down to approx. −3 ° C, but optimal oil and fuel resistance. As the acrylonitrile content increases, the elasticity and gas permeability decrease, and the compression set deteriorates.

Materials based on this synthetic rubber are suitable for a wide range of applications due to their good technological properties. In particular, radial shaft seals , sealing elements for hydraulics and pneumatics as well as O-rings are manufactured in large numbers from NBR-based materials. They are used to make seals, hoses, rubber gloves, and rubber threads.

Chemical stability

- Good swelling resistance in aliphatic hydrocarbons , e.g. B. propane , butane , petrol , mineral oils ( lubricating oils , hydraulic oils of groups H, HL and H-LP) and mineral oil-based grease, flame-resistant pressure fluids of groups HFA, HFB and HFC, vegetable and animal oils and fats, light heating oil, diesel fuel. Some materials are particularly resistant in hot water up to temperatures of 100 ° C (sanitary fittings) and inorganic acids and bases if the concentration and temperature are not too high.

- Medium swell resistance in fuels with a high aromatic content (super fuel).

- Strongly swelling in aromatic hydrocarbons , e.g. B. benzene , chlorinated hydrocarbons, e.g. B. trichlorethylene , flame-retardant hydraulic fluids of the HFD group, esters , polar solvents and in brake fluids based on glycol ethers .

- Thermal range of application: depending on the composition of the mixture between −30 ° C and +100 ° C, briefly up to 130 ° C; the material hardens at higher temperatures.

With special mixtures, the low-temperature flexibility reaches down to −55 ° C through the use of plasticizers.

- Due to the double bonds present in NBR, the temperature and ozone resistance is limited. These are converted into single bonds by hydrogenation, which significantly improves the temperature and ozone resistance. This material is known as HNBR .

Blends with PVC are also common to improve ozone resistance. Typically a 70% NBR / 30% PVC blend is used here.

Web links

- Product description on the website of the Dürholdt company (accessed on March 2, 2016)

Individual evidence

- ↑ Data poly (acrylonitrile-co-butadiene), acrylonitrile 37-39 wt.% At Sigma-Aldrich , accessed on 22 April 2017 ( PDF ).

- ↑ This substance has either not yet been classified with regard to its hazardousness or a reliable and citable source has not yet been found.