Antonin Chmel

Antonín Chmel (1850-1893, in German also Anton Chmel) was a Bohemian entrepreneur in a smoked goods factory and exporter of Prague ham , with headquarters in Vinohrady in Prague.

biography

Chmel came from a poor bourgeois family with many children, his father was a butcher . At the age of 14 he left his parents' house and went on a hike first to Prague , later to Vienna and then to the Royal Vineyards . At the age of 21 he decided to settle down there as a businessman. By the time he was from a humble tradesman to a viewed exporter high work.

The orders increased over time, the previous workrooms as well as the stock of goods proved to be inadequate. Chmel bought part of the extensive estate »Zvonařka« in the Royal Vineyards, and shortly afterwards a simple work place was built, which later grew into a factory and was expanded. The domestic and foreign press praised the system very much. Chmel was held in high esteem among his fellow citizens.

For his merits and due to the high quality of his products, Antonín Chmel was appointed imperial and royal court purveyor , royal Bavarian and royal Romanian court purveyor.

After his death in 1893, his widow took over the business and was able to successfully manage and expand it. The end came with the end of the Second World War when the communist rulers confiscated and nationalized the company. With the Iron Curtain, a large part of the traditional sales market also closed and the company perished.

factory

At the end of the 19th century, the city of Königliche Weinberge grew significantly with the construction of public buildings and various factories. The most important of these factories was that of Antonín Chmel, a producer of smoked goods . The factory was on the bottom of the extensive »Zvonařka« estate, which lay on the steep side slope of the Nusler valley . The factory with its workshop, the machine house with its 26 meter high chimney and the residential buildings could be seen from the Nusler valley lowlands.

Before 1900, the whole system was divided into three parts, namely the actual production site with the associated farm buildings such as wagon shed, stables, etc., then the artificial cooling system with the machine and boiler house and finally the wing with the residential buildings, where the factory comptoirs , Workers accommodation, etc. were housed.

Production site

The first part was a wide, secluded room, where the incoming raw material found its place in the weighing machine and was then cut in the so-called Prague way. The raw material was then sorted in another room for further preparation. In the rear wing of this department, the stored intestines and various articles were stored up to the ceiling, all of which were necessary for the manufacture of smoked goods. The expedition room was directly connected to this department, where the finished goods were waiting for their further destination. Thousands of hams and other smoked products left here every year for export to all sorts of countries. The hams enjoyed a worldwide reputation for their high quality and were legally protected by a trademark.

The actual workshop , which was equipped with work machines and marble work tables, was lined up next to the expedition room. The floor was cement for easier and better cleaning. After the workshop, there were the floor-to-ceiling smoke chambers in which 10,000 kilograms of goods could be smoked at once within 24 hours.

The factory had many work and storage cellars, where the supply of various materials in partly raw, semi-finished or finished state was scattered or stored in huge barrels. Around 1900 the inventory that the factory needed to operate had an average value of 100,000 to 150,000 fl. Oe. W .

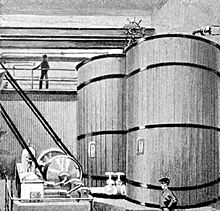

Cooling system

The second part of the factory was the artificial cooling system, where the machine house with the boiler house was also located. Two steam engines , at 100 horsepower , formed the main agent of the whole plant. Not only the machines in the machine house, but also all the work machines in the workshop and the cellar elevator were located here. Two chillers ( System Linde ) with two salt water pump in addition to a sprinkler capacitor that were on the first floor of the nacelle, the desired cooling produced up to a degree of heat for the vast cellars and storage rooms of the factory as well as the large underground rooms of actual cooling system. This cooling system was rented to butchers, selcher, venison dealers and others and was kept odorless by a ventilation device despite large stocks of meat and other raw materials. Also noteworthy was the ice-making machine located in the machine house, which made the artificial ice for the factory and customers. This could produce 16 centimeters of ice within eight hours .

Residential complex

Two electro dynamo machines , which were housed in connection with accumulators in the basement of the machine house, provided the electrical lighting of all work rooms and cellars of the establishment , the whole cooling system and the large factory yard, as well as the adjoining residential buildings. The residential buildings, in which the factory comptoirs and workers' logis were accommodated, were equipped with a steam heating system. A 37 meter deep well with a 35 meter long tunnel in the garden on the valley slope supplied the necessary cooling water. The factory employed an average of 10 civil servants and around 100 workers, and around 1900 the vehicle fleet consisted of 12 wagons and six pairs of horses.

Individual evidence

- ^ Antonin Chmel . In: Presented by the industrialists of Austria under the high protectorate of His K. and K. Highness of the Most Serene Archduke Franz Ferdinand (Hrsg.): Die Groß-Industrie Oesterreichs . Festival ceremony for the glorious fiftieth anniversary of the reign of His Majesty the Emperor Franz Josef I. Volume 5 . Leopold Weiss, Vienna 1898, XII. Agricultural industry, food and beverages, p. 359-361 .

- ↑ a b c Antonín Chmel . In: The large-scale industry of Austria . P. 361

- ↑ a b c Antonín Chmel . In: The large-scale industry of Austria . P. 359

- ↑ Court and State Handbook of the Austro-Hungarian Monarchy for 1900. K. k. Court and State Printing House, Vienna. P. 220

- ^ Robert Šimek: Antonín Chmel Rytíř řádu pražské šunky. Profit.cz, March 18, 2007, accessed on September 21, 2011 (in Czech, Pražská Zvonařka je dnes moderním rezidenčním centrem. Nebyla jím ale vždy. Kdysi zde totiž sídlil podnik, který Ottův slovník. Naučný toší uvádíš ". Závod známého výrobce pražské šunky Antonína Chmela. Dušená šunka se kdysi v českých zemích vyráběla jako ostatní uzená a vařená masa.).

- ↑ Karel Sladký: Kde nakupovali pražští labužníci. zijemenaplno.cz, accessed on September 21, 2011 (Czech, Hlavní město české dlouho nemělo ústřední tržnici, zato tu bylo několik slavných trhů staroměstských: uhelný, vaječný to uhelný, vaječný to poskoldé malice zelný, ovocný, bramborový (v Kotcích).).

- ↑ a b c d Antonín Chmel . In: The large-scale industry of Austria . P. 360