Boston Manufacturing Company

| Boston Manufacturing Company | ||

|---|---|---|

| National Register of Historic Places | ||

| National Historic Landmark District | ||

|

The factory complex in 2009 |

||

|

|

||

| location | Waltham , Massachusetts , United States | |

| Coordinates | 42 ° 22 '23.2 " N , 71 ° 14' 8.9" W | |

| surface | 2.5 acres (1 ha ) | |

| Built | 1813 | |

| architect | Paul Moody | |

| NRHP number | 77001412 | |

| Data | ||

| The NRHP added | 22nd December 1977 | |

| As NHLD declared | 22nd December 1977 | |

The Boston Manufacturing Company (BMC), founded by Francis Cabot Lowell in 1813 , established the first factory in the United States as a manufacturer of textiles in the 19th century to combine several production steps under one roof. At the same time, it was for a long time the largest employer in the USA with more than 300 employees. Although the name suggests otherwise, the building is located in Waltham in the state of Massachusetts of the United States . The company was listed on the National Register of Historic Places (NRHP) as a National Historic Landmark District in 1977 and is now an industrial museum .

architecture

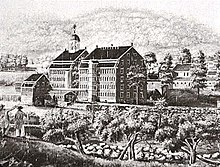

Construction work on the factory halls began under the supervision of Paul Moody in 1813 with the establishment of the first cloth factory. Further extensions followed in 1816, 1821 and 1843, of which the building completed in 1821 no longer exists. The other three are right next to each other and form a uniform, five-story facade with a length of around 97.5 m and a width of 13.7 m. The NRHP entry relates to these three oldest structures and the adjoining property up to the Charles River . The other, more recent buildings and objects on the BMC property were classified as not contributing to the relevance.

Shortly after the basement of the first building was completed, Moody set up a workshop there, in which he and his partner Lowell worked together on designs for their new textile machines. The machines in the completed factory were powered by a water wheel in the basement installed by Jacob Perkins . Carding was carried out on the ground floor, the spinning mill was on the first floor and the weaving mills were housed on the upper two floors .

When the new machines and processes had proven to be successful after the start of production, the factory was gradually expanded and new buildings were added, which was made possible in the 1840s primarily by improving energy generation.

The three factory buildings to which the NRHP entry relates have only changed marginally over time. Textiles were produced there until the 1970s - most recently by the Puritan Dress Company - so that the interior areas are largely preserved in their original state.

Historical meaning

The textile industry in New England was the origin for the industrialization of the United States, serving as a testing ground for industrial processes. The beginnings go back to the 1790s, when William Almy and Moses Brown used the ideas and skills of the English immigrant Samuel Slater to jointly open the first commercially successful textile factory in the USA in Providence .

The idea found many imitators, so that in 1810 there were already 168 textile factories with 90,000 weaving spindles . The market was fiercely competitive, with businesses competing with inexpensive imports from England, as well as for skilled labor and investors. Jefferson's trade embargo and the British-American War that followed shortly afterwards changed the situation, however, by excluding foreign competitors from participating in the market and providing investors with fresh money to set up additional textile factories. These new companies also included the Boston Manufacturing Company, which with its innovations fundamentally redefined the processes of textile production.

The main driver and architect behind the BMC was Francis Cabot Lowell , who studied the British textile industry in detail while traveling through Great Britain and memorized the ideas and plans for it, as the export of these technologies was banned. After his return, he founded the Boston Manufacturing Company based in Waltham on February 23, 1813, together with his brother-in-law Patrick T. Jackson, his cousin Benjamin Gorham , Uriah Cotting and other investors such as Nathan Appleton . Lowell's plans were to combine the spinning and weaving processes under one roof for the first time, to mechanize the entire company and to drive the machines with water power.

The consortium chose a site on the Charles River on which a paper mill had previously been operated. In addition, the highly qualified engineer Paul Moody was hired as “ superintendent of construction ” (comparable to the position of construction manager ), as Perkins had rejected a corresponding offer. After around a year of construction, the first building with external dimensions of around 27.5 m × 13.7 m was completed and put into operation in November 1814. Lowell designed a power chair that Moody initially built as a model. Towards the end of the year, the self-constructed loom was ready for use and, along with other bought-in machines, served as the basis for running the company. The BMC mainly hired women from the surrounding farms for whom it had built its own accommodation.

Due to the novel combination of all production and processing steps from raw materials to the finished product under one roof and in a single organizational unit, the BMC was the first company in the United States to be referred to today as a “modern factory”. This "Waltham model" was copied by many companies - including from other industries - and had a significant impact on the incipient industrialization of the USA. With Lowell , the first industrial city in the United States to be planned on the drawing board was built on this principle .

The power chair developed by Lowell ended the country's reliance on British technology. Moody and his assistants succeeded in making significant technological advances in almost every step of textile manufacture; Among other things, Moody invented the warping machine , improved the roving production process and developed a throttle for the “dead-spindle” spinning process . Moody's adaptations of British developments and his own inventions, which he made between 1814 and 1824 in the BMC workshop, were by far the most important in the American textile industry and formed the basis for the business activities of the Saco-Lowell Shops , which for a long time was one of the largest manufacturers of Machines for textile production in the USA were.

In the first ten years of its existence, the BMC expanded considerably, which also had an impact on Waltham, which was until then rather rural. BMC's textiles were competitive with British imports, allowing the company to make substantial profits, some of which it invested in building schools and churches in the city. The company also established a library and the city's first fire station.

At the height of its success, Francis Lowell died in 1817. Jackson and Appleton then founded the Merrimack Manufacturing Company with other investors - known as The Boston Associates - in the city of Lowell, named after their deceased partner. However, the BMC was unable to build on its previous successes and had lost most of its former importance by 1850. In 1929 the company was finally closed.

See also

literature

- George R. Adams: National Register of Historic Places Inventory - Nomination Form. (PDF) United States Department of the Interior , National Park Service , June 1977, accessed December 9, 2016 .

- Samuel Batchelder: Introduction and early progress of the cotton manufacture in the United States . Little, Brown and Co., Boston 1863, OCLC 11051173 .

- Kenton Beerman: The Beginning of a Revolution: Waltham and the Boston Manufacturing Company. (PDF) 1994, archived from the original on May 8, 2012 ; accessed on December 9, 2016 .

- John W. Cox, L. Michael Kaye: Waltham's industrial heritage . Waltham Voccational High School, Waltham, MA 1981, OCLC 866422353 .

- Steve Dunwell: The run of the mill: a pictorial narrative of the expansion, dominion, decline, and enduring impact of the New England textile industry . DR Godine, Boston 1978, ISBN 978-0-87923-249-8 .

- Alex Groner: The American heritage history of American business & industry . American Heritage Pub. Co., New York 1972, ISBN 978-0-07-001156-4 .

- Kenneth F. Mailloux: The Boston Manufacturing Company of Waltham, Massachusetts, 1813-1848: the first modern factory in America . Boston University, Boston 1957, OCLC 5857437 .

- Waltham through Time Page 8. The Waltham Museum Inc., accessed December 9, 2016 .

- Caroline F. Ware: The early New England cotton manufacture: a study in industrial beginnings . Russell & Russell, New York 1966, OCLC 237583 .

Web links

- Historic American Engineering Record: Boston Manufacturing Company, 144-190 Moody Street, Waltham, Middlesex County, MA. Library of Congress , accessed December 9, 2016 .