Cellulose hydrate

Cellulose hydrate or cellulose glass , known under the name cellophane and the former brand name cellophane (from Kalle & Co. AG , Wiesbaden, or the parent company Hoechst AG , Frankfurt), is one of the oldest plastics for packaging that comes into direct contact with food . It is a thin, colorless and transparent film made from regenerated cellulose with the characteristic "cellophane attack" and crackling effect.

Cell glass is neither particularly plastic nor elastically deformable and can only be stretched to a small extent. However, cell glass is a plastic that can be made entirely from renewable instead of fossil raw materials . The material composition is similar to that of a viscose fiber .

Cell glass lets water vapor pass through. In this way, appropriate packaging prevents condensation from forming inside . The barrier function decreases in the event of water contact or high humidity. In order to reduce the water vapor permeability of the cell glass, it is partially coated with other plastics. In this way, the cellulose film gains additional desired properties, but it loses its environmental impact. Because pure cell glass can be composted or disposed of with waste paper. The coated film, however, is no longer completely biodegradable .

history

Cell glass was invented in 1908 by the Swiss Jacques E. Brandenberger and brought onto the market under the brand name Cellophan . The name is derived from the raw material cellulose and ancient Greek διαφανής diaphanés ("translucent", "transparent"). Until the 1950s, cell glass was practically the only packaging film. The fact that the packaged goods remained visible made the pioneering plastic a great success. It was only after the Second World War that a series of plastic films followed, the properties of which had to be determined much more in line with the market for their respective task, including in particular polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP) and polystyrene (PS). Today, polyester films such as PET are also widespread.

Manufacturing

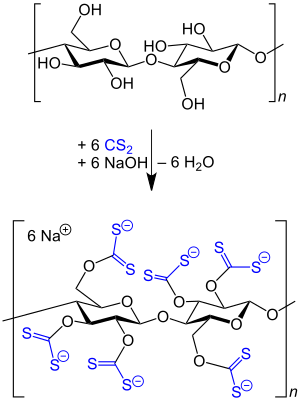

To produce the cellulose hydrate, chemical pulp from what is known as wood pulp, a cellulose pulp, is dissolved in sodium hydroxide solution (NaOH) and carbon disulfide (CS 2 ). The resulting viscose (viscous mass) is cleaned by means of filter presses and poured through a slotted nozzle into a precipitation bath of dilute sulfuric acid , whereby the cellulose precipitates. The resulting film is then soaked in several baths to remove residues of the Glauber's salt (sodium sulfate) formed in the precipitation bath . After passing through the last bath, to which glycerine has been added as a plasticizer , the film is dried on heated rollers and then wound up.

The production costs of cell glass are relatively high; only a few companies still manufacture it today. The film can be printed or painted, it can be glued and also thermally connected ( welded ).

use

In the packaging industry, because of its special microclimate properties, the more expensive cell glass is preferred to other, cheaper plastic foils for certain goods and goods. To this day, cigarettes and tobacco products , confectionery , baked goods, cheese, meat products and some other foods , but also paper goods , medicines , clothing and flowers are preferably packaged in cell glass instead of plastic film. Cell glass is also still used as insulation (capacitors, cables, coils) in the electrical industry.

At the beginning of the 20th century, the Loeser & Richter pasta factory was one of the first German companies to wrap their branded products in cellophane without exception. In the company's own in-house announcement "After the store closes", it was stated: "Cellophane" and the good quality of Anker were the two factors that, on the one hand, increased and broadened the reputation of the Anker brand, but on the other hand also opened up new avenues for "cellophane" and in the to participate equally in the success.

Cellulose glass has long been used with a rubber ring to close a jar of homemade jam. For this purpose, canning jars with thread for sheet metal lids can be used. Such round sheets of canning film are often sold in combination packs with rubber rings and adhesive labels. The film has to be moistened, which makes it supple and allows it to swell, so it lies tightly against the edge of the glass and contracts as it dries. Since the gas space above the hot jam contains a lot of water vapor and this condenses or diffuses through the (airtight) film, and the enclosed air contracts by cooling, the film arches inward.

Small bags (cross-bottom bags) made entirely or partially of cell glass are used for gentle packaging that shows the contents, especially nuts and dried fruits (containing some water).

Typical film thickness is 21 µm (30 g / m² basis weight ) and more. Cellulose glass with a thickness of 7 to 90 µm (10 to 120 g / m²) is produced. Cellular glass strips are also woven or otherwise used for textiles.

Coating cellulose with varnish or layers of plastic also changes properties such as the coefficient of sliding friction and the pull-off force (from the stack).

For some time now, see-through cigarette paper has also been found , which is made using the same process as cellophane. In the early 1960s, when the hang glider was first used, cellophane was used to cover the wings. Until the 1970s, scotch tape was also made from cell glass. Cellophane is also used as a membrane material for dialyzers .

Ecology and environment

The production of cell glass requires many resources such as wood, water, energy, air. While pure cellulose hydrate can be disposed of via composting without any problems , the disposal of coated cellulose glass is more complicated and it is mostly thermally recycled . The use is considered to be problem-free, with the requirements for the production of (coated) cellulose glass being strictly regulated in the Consumer Goods Ordinance .

Individual evidence

- ↑ Cellophane trademark register

- ↑ a b Liesl K. Massey: Permeability Properties of Plastics and Elastomers, 2nd Ed. Cambridge University Press, 2003, ISBN 978-0-08-095057-0 , p. 3.

- ↑ Sukhareva: Polymers for Packaging and Containers in Food Industry. CRC Press, 2008, ISBN 978-9-004-18820-4 , p. 112.

- ^ Siegfried Hauptmann : Organic Chemistry , 2nd reviewed edition, VEB Deutscher Verlag für Grundstoffindindustrie, Leipzig, 1985, p. 652, ISBN 3-342-00280-8 .

- ^ After closing time, June 1939.

- ↑ Cellophane / cell glass cross- bottom bag transbags.de, accessed November 7, 2011.

- ↑ Zellglasbändchen In: Herbert M. Ulrich: Handbook of the chemical investigation of textile fibers, Springer-Verlag, 2013, p. 311.

- ↑ Belt pull-off (table) Jochen Hertlein: Investigations into changes in the barrier properties of metallized plastic films during machine processing, Herbert Utz Verlag, 1998, p. 40 f.

literature

- Hans-Josef Endres, Andrea Siebert-Raths: Technical biopolymers. Hanser-Verlag, Munich 2009; P. 140. ISBN 978-3-446-41683-3 .