Hollow fiber

A hollow fiber is understood to be a fiber both as a filament and as a spun fiber which has one or more continuous air-filled cavities in cross section. Hollow fibers can be spun from melts or solutions using different methods. The filaments with a continuous cavity are also referred to as hollow threads. Segmented hollow fibers also exist; H. the cavity is not continuous, but is formed in segments.

textiles

In the textile industry , hollow fibers are produced as insulating material or, because of their capillary forces, as absorbent filling material. The cotton fiber is a hollow fiber of natural origin. Synthetic hollow textile fibers based on polyamide are z. B. Anso-tex , based on polyester z. B. Hollofil , Quallofil (7-channel), Coolmax (4-channel or 6-channel) or Thermicfibre (4-channel or 6-channel) as well as polypropylene-based z. B. D. Fens and Asota M40

Hollow fibers made from PET filaments with multi-hole structures are predominantly used for both house textiles and clothing materials, e.g. B. with 3, 4 or 7 continuous cavities, so-called channels. Characteristic are the good heat retention, the reduced mass, the moisture dissipation and, above all, with the siliconized finish, the softness. For jersey , interlock and tricot fabrics as well as for nonwovens, in addition to single-channel, predominantly four-channel PET hollow fibers, which have a high degree of structural elasticity. For house textiles, single and multi-hole PET fibers are used as filling material in quilts, pillows, beds and in upholstered furniture production.

With PA 6.6 hollow filaments, textiles that are 30 to 40% lighter and 15% better insulating properties can be produced than with normal PA 6.6 yarns. These hollow filaments are used in sports and outdoor clothing and for jackets and coats.

PP hollow fibers with a 3-channel structure are mainly used in the carpet sector. They serve as pile material in tufted carpets , pure and mixed with wool, and ensure a very good ability to recuperate .

Lightweight construction

A special form of the glass fiber used in composite materials , the hollow glass fiber , has a hollow cross-section and thus enables the total weight of the hardened laminates to be up to 40% lower .

optics

In optics, in addition to conventional light guides with full cross-sections, hollow fibers are also used to conduct light. Such hollow fibers consist either of a polymer (see also polymer optical fiber ) or of glass (see also glass fiber ).

The light cannot be guided by total reflection as with conventional fibers , but by grazing incidence by reflection or with the help of a photonic crystal (" hollow-core photonic crystal fiber ", HC-PCF for short, from English hollow-core photonic-crystal fiber or HC -PBF for hollow-core photonic bandgap fiber ).

Hollow fibers have the following advantages over conventional fibers without a cavity:

- the interaction of the light with the fiber material is less, which is noticeable in some spectral ranges as less attenuation

- Disturbing non-linear optical effects at very high light outputs are reduced and the destruction of the fiber by too intense light is prevented.

In addition to guiding light, hollow glass fibers can also be used to carry out functional elements, e.g. B. of optical fibers.

Membrane technology

In membrane technology , hollow fibers (also called capillary membranes or hollow fibers) are produced with partially permeable structures, so that the walls of the fibers act as a membrane. For the construction of filter modules hollow fibers with a length between 25 and 100 cm into modules of up combined into many square meters filter surface, and at both ends against hydraulic short-circuiting (leakage between the permeate side and the retentate side of a filtration unit ) encapsulated ( potted ).

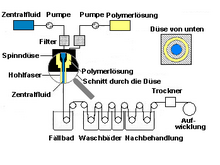

Manufacturing

Hollow fiber membranes today mostly consist of polyethersulfone , polysulfone or polyacrylonitrile (PESU, PSU, PAN). But ceramic or sintered metal are also used. Polymer fibers are usually produced using phase inversion in a wet spinning process. Some of them are also sintered (PTFE, PP, PE) or extruded and stretched .

Inflow

Hollow fiber membranes can be approached in two directions:

- In - Out ( dialyzer ; juice filtration)

- Out - In ( membrane activated sludge reactor )

and in two ways:

- Tangential flow filtration (countercurrent principle), whereby you experience a certain self-cleaning due to the pinch effect (only with In - Out).

- Dead-end filtration , which is energetically cheaper

. The choice of processes and their combination depends on the expected load and the particle size.

Areas of application

They are of increasing importance in drinking water and wastewater treatment (MBR) but also in bioprocess engineering .

literature

- Munir Cheryan: Handbuch Ultrafiltration , B. Behr's Verlag GmbH & Co, Hamburg 1990, ISBN 3-925673-87-3

Web links

- Polyvinylpyrrolidone for Membrane Applications

- Technical data - hollow glass fibers. (PDF) R&G fiber composite materials, January 2010.

Individual evidence

- ↑ Günter Schnegelsberg: Manual of the fiber - theory and systematics of the fiber. Deutscher Fachverlag, Frankfurt am Main, 1999, ISBN 3-87150-624-9 , p. 202.

- ↑ Hans-J. Koslowski: Chemical fiber - Lexicon. 12th, expanded edition. Deutscher Fachverlag, Frankfurt am Main 2009, ISBN 978-3-87150-876-9 , p. 105.

- ↑ Franz Fourné: Synthetic fibers: production, machinery, Features: Manual for system planning, machine design and operation. Carl Hanser Verlag, Munich Vienna 1995, ISBN 3-446-16058-2 , p. 550

- ↑ Double nomination for Kelheim Fibers at the ITMA Future Material Awards. In: C2 Coating & Converting. October 17, 2014, accessed March 21, 2020 (Includes the microscopic cross-sectional image of the segmented Bramante fiber).

- ↑ Walter Loy: Chemical fibers for technical textile products. 2nd, fundamental revised and expanded edition. Deutscher Fachverlag, Frankfurt am Main 2008, ISBN 978-3-86641-197-5 , p. 37.

- ↑ Walter Loy: Chemical fibers for technical textile products. 2nd, fundamental revised and expanded edition. Deutscher Fachverlag, Frankfurt am Main 2008, ISBN 978-3-86641-197-5 , p. 45.

- ↑ Walter Loy: Chemical fibers for technical textile products. 2nd, fundamental revised and expanded edition. Deutscher Fachverlag, Frankfurt am Main 2008, ISBN 978-3-86641-197-5 , p. 57.

- ^ Surgical instrument . May 2, 2002 ( freepatentsonline.com [accessed July 19, 2018]).