Induction hob

An induction hob is a hob in which the ferromagnetic cookware is heated by inductively generated eddy currents and magnetic reversal losses.

Mode of action

The power is transmitted in the form of an alternating magnetic field through an insulating, cold plate (usually glass ceramic) into the bottom of the cookware (iron alloy) and converted into heat there due to induced eddy currents and magnetic reversal losses. As there is no hotplate - as with conventional electric stoves - has to be heated in order to conduct the heat from it into the bottom of the pan, the efficiency of the induction process is higher for short cooking and roasting processes.

Below the cooking surface to is one of a high frequency - current -carrying coil which generates the magnetic alternating field. The usual frequency is in the range from about 25 to 50 kHz .

Although induction heating in principle - as with induction ovens - would also work with other conductive pot bottoms (e.g. also those made of copper), pots and pans for induction hotplates must have a layer of ferromagnetic material on the bottom at least on the outside (can be recognized by the fact that a Magnet sticks to the floor). For good efficiency in converting electromagnetic energy into thermal energy, this material - as is usually the case with iron alloys - must also have a significantly higher specific electrical resistance than the highly conductive HF copper of the induction coil.

Other aspects of the choice of ferromagnetic alloys as soil material include: a .:

- Ferromagnetic material in the bottom of the pot bundles the alternating magnetic field precisely there, while in the case of non-ferromagnetic pot bottoms, less bundled, it could spread more strongly in the room, which can lead to undesirable interactions with the environment of the coil through which current flows (see electromagnetic environmental compatibility ).

- Due to the skin effect , the alternating magnetic field only generates its eddy currents in a relatively thin outer layer of the bottom of the pot. As a result of this, as well as the fact that the ohmic resistance of the induction coil is relatively small in contrast to that of the ferromagnetic base material (the eddy current in the bottom of the pot is about as high as the flow through the induction coil), most of the electrical power supplied in the bottom of the pot is converted into thermal power implemented.

- Another part of the energy introduced into the bottom of the pot is converted into thermal energy by the loss of magnetization ( hysteresis ). This corresponds to about 1/3 of the heating output.

Induction-compatible cookware usually fulfills these requirements and can be recognized by the symbol that shows the wire coil of a coil in a square on the bottom of the pot or pan . However, this symbol is not guaranteed to function. A pot can only be tested for induction suitability in a practical test. Thicker floors are advantageous for better heat distribution.

Most induction hobs automatically switch off the exciter field as soon as there is a too small, unsuitable or even no pot on the hob. However, the electronics can be fooled by a metal object lying on top of it, which they mistake for a pot (e.g. an iron plate).

construction

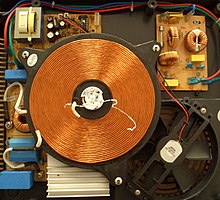

the large copper coil is visible, including the electronics; top right: line filter; bottom right: fan for cooling; bottom left: blue capacitors of the resonance circuit; below, mounted on the aluminum heat sink: IGBT ; top left: auxiliary power supply; white button in the middle: temperature sensor

A large, flat, single-layer coil made of high-frequency stranded wire generates the high-frequency alternating magnetic field under the cooking surface. Together with capacitors, it forms an oscillating circuit that is set into resonance by one or more IGBTs (switching transistors) ( resonance converter or Royer converter).

There are various circuit concepts for power control:

- The transistor switches are fed from a controllable DC voltage intermediate circuit. The direct voltage is obtained from the mains alternating voltage via controllable semiconductor diodes ( thyristors ).

- the excitation frequency is varied - if it is outside of resonance, the coil current and power decrease

- A pulse width control is used that switches the full power on and off (frequency approx. 0.5 Hz). The ratio of switch-on to switch-off time determines the heating output.

Advantages and disadvantages

The reaction time is short and the cookware heats up very quickly. This allows the cooking process to be controlled better than with a hob with thermally inert electric hotplates .

Some of the electrical energy is lost, however, because only 80% to 90% of it can be converted into a magnetic field, even if the hob is completely covered by the bottom of the pot or pan. However, the proportion of unused energy through convection , thermal radiation and heat conduction in the hotplate is lower than with conventional cooker types, since the hotplate does not need to be heated beforehand. Up to 30% energy is saved when cooking.

The glass surface under the pot is only heated secondarily through contact with the pot. Food residues hardly burn onto the hob, which makes cleaning easier.

Only magnetizable pots can be used on an induction hob. All non-metallic and non-magnetizable vessels made of 18/10 stainless steel or non-ferrous metals are unsuitable. However, so-called induction adapters are commercially available, which are plates made of ferromagnetic material that are placed between the pot and the hob. The hob then heats this plate, which in turn transfers the heat (like a conventional hotplate) to the pot. However, additional energy is lost here, but the previous cookware can still be used.

A fan is usually installed to cool the electronics of the hob. The cooking process can make audible noises such as chirping and humming due to subharmonic undertones and the modulation of the working frequency. Dogs and cats may also hear the basic frequency of the magnetic forces (double the working frequency).

The electronics are much more complex than other electric stoves, especially the high-performance power supply, which is not necessary in conventional electric stoves. In the event of a defect, the repair is correspondingly expensive.

Induction hotplates are only sometimes profitable compared to the competing processes of gas, glass ceramic and radiant heating (halogen hob) due to the high acquisition costs. However, according to the Munich Environmental Institute, they have the best energy efficiency.

Electromagnetic environmental compatibility (EMUV)

In 2006/07, the Swiss Federal Office of Public Health had induction cooking stoves checked for compliance with the ICNIRP reference values for magnetic field exposure . The basis for establishing the reference values for the external fields are basic limit values for field strengths inside the body, for which the occurrence of certain health impairments has been published in the scientific literature. The reference values of the external fields, here the magnetic flux density, are derived from the lowest internal field size at which such an occurrence is described for the respective frequency range, assuming the maximum coupling of the external field to the exposed person. A safety factor is also included, which also takes into account the data quality and individual differences in sensitivity. Even in the worst case, the reference value cannot lead to the basic restriction being exceeded. With the frequencies used in induction cooking appliances, a neuronal excitation (tingling, muscle twitching, etc.) caused in the human body is decisive. The ICNIRP guidelines of 1998 determined a reference value of the magnetic flux density of 6.25 µT from the studies published up to then with a safety factor of 50 . The 2010 guidelines were able to reduce the safety factor to 10 due to the improved data situation due to publications in the meantime and thus set the reference value at 27 µT.

When used as intended, the tested devices at a horizontal distance of 30 centimeters from the device, in accordance with the applicable measurement regulations, complied with the reference value of 6.25 µT of the ICNIRP guidelines applicable at the time. In the case of realistically smaller horizontal distances, this value was partially exceeded, at a distance of 1 centimeter in front of the device it reached a maximum of 10 µT, and up to 26 µT at the side and rear. As a result, the Swiss Federal Office of Public Health and the German Federal Office for Radiation Protection recommend a minimum distance of 5 to 10 cm from the front edge of the cooker.

Significantly higher flux densities of up to 84 µT were measurable above the hob directly next to the cookware. In the event of improper use due to the use of pans that are too small or positioning that is not centered on the cooking zone, so that the cooking zone is not completely covered, or the use of pans with an uneven base or those that are not ferromagnetic, even stronger stray fields arise. Since the reference values assume a maximum coupling, i. H. maximum exposed body cross-sections, based on what is not given here, the basic restrictions are not necessarily exceeded. To clarify this question, another study on the effects in the human body was carried out at the end of 2011 on behalf of the Swiss Federal Office of Public Health.

In principle, the function of pacemakers can be influenced by the alternating magnetic fields . Even if modern devices are protected against such interference, manufacturers recommend using a pacemaker to keep a minimum distance of 40 cm from an induction hob.

The induction coil and pan on top form an electrical capacitor . When the induction coil is switched on , the pan is slightly electrically charged and continuously reloaded. If the pan is touched, a small leakage current can flow through the body. In order to avoid such leakage currents during cooking, the Swiss Federal Office of Public Health recommends the use of non-metallic cooking utensils. Modern inductors are shielded against such currents. A graphite layer is applied to the cover sheet of the inductor. This graphite layer is in turn connected to the earth connection. With older inductors, voltages of over 200 V can occur in the cookware. People perceive this as a mild to moderate tingling sensation in sensitive areas such as the back of the hand (blood vessels). After the above grounding, the voltage must not be higher than 30 V.

Electromagnetic Compatibility (EMC)

Interference emission:

Induction hobs work in the lower long wave range and emit electromagnetic waves at these frequencies. However, the working frequency is below civil long-wave transmitters (less than 100 kHz) and also below the agreed lower measurement limit for testing electromagnetic interference (150 kHz).

However, there may be an interaction with radio-controlled clocks , as these work on the frequency 77.5 kHz in Germany. This communication might be disturbed during the synchronization with the DCF77 transmitter. After switching off the hob, however, this fault should no longer exist.

Further interference at higher frequencies is generated by the power semiconductors ( IGBT , thyristors ); In terms of network feedback (line-related interference) and radiation, they must be as low as with other electrical devices and are guaranteed by the manufacturer with the CE mark.

If the minimum distance to an induction hotplate is not reached, a general malfunction or even permanent damage can occur in electronic circuits. B. with RFID - transponders - cannot be excluded.

Interfering immunity:

Induction cookers contain complex electronic assemblies and are therefore potentially more sensitive to transient overvoltages in the power grid than other electric cookers. The protection of the electronics through suitable measures is the responsibility of the designer and must also be guaranteed by means of the CE mark.

history

The first patents for induction cookers were issued in England shortly after 1900. The invention was not used in practice. In 1956, Frigidaire , then a subsidiary of General Motors , demonstrated some experimental devices to the public in the USA , in which a newspaper was placed between the stove and the pot that did not catch fire even though the water in the pot began to boil . The single plate was also covered with a bell jar. Series production was not carried out here either. Between 1973 and 1975 Westinghouse manufactured a white ceramic induction cooker that was sold under the name Cool Top 2 (CT2). The cost of this device was enormous and, including the cookware that was also sold, was $ 1,500, which, converted into purchasing power in 2017, corresponds to an amount of $ 8,260. Possibly because of this, the demand was only low.

At the end of the 1970s and 1980s, Thomson-Brandt manufactured large induction cookers with several kilowatts of power for canteens and large kitchens in France . From around the mid-1980s, Kenmore, a subsidiary of Sears , began selling induction cookers in the USA that were combined with a self-cleaning oven.

Today most induction cookers in Europe are sold in France. In 2017 they had a market share of 55.8% of all newly sold kitchen stoves.

Market development

| year | proportion of |

|---|---|

| 2004 | 12% |

| 2005 | 14% |

| 2006 | 18% |

| 2007 | 23% |

| 2008 | 28% |

| 2009 | 30% |

| 2010 | 34% |

Web links

- Page no longer available , search in web archives: Swiss Federal Office of Public Health: Exposure to magnetic fields from induction cookers . Study.

- Explanation of the induction cooker and induction

Individual evidence

- ↑ Llorente S et al. A comparative study of resonant inverter topologies used in induction cookers. Seventeenth Annual IEEE Applied Power Electronics 2, 1168-1174. 2002.

- ↑ Michael Bockhorst: Saving energy → Induction hotplates: When is it worth buying? (Energy saving tips / save money and energy with ENERGIEINFO.DE). In: energieinfo.de. Retrieved April 7, 2019 .

- ^ Josef Scholz: Induction. Retrieved April 7, 2019 .

- ↑ Energy efficiency - Miele induction hobs. (No longer available online.) In: miele.de. Miele & Cie. KG, archived from the original on April 15, 2016 ; accessed on April 7, 2019 .

- ↑ Stainless steel and induction »Does that go together? In: Hausjournal.net. M15 Internetdienstleistungen GbR, February 2, 2016, accessed on April 7, 2019 (German).

- ↑ Hobs - induction cooks faster - Stiftung Warentest. In: test.de. Stiftung Warentest, accessed on April 7, 2019 .

- ↑ Bayerischer Rundfunk Barbara Jelen: Hot water: kettle or saucepan? August 20, 2016 ( br.de [accessed April 7, 2019]).

- ↑ Clementine Viellard, Albert Romann, Urs Lott, Niels Kuster: B-Field Exposure from Induction Cooking ( Memento of the original from July 19, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. . Zurich: IT'IS Foundation, 2007.

- ↑ Federal Ministry for the Environment, Nature Conservation and Nuclear Safety, Federal Office for Radiation Protection (transl.); International Commission on Non-Ionizing Radiation Protection: Guidelines for the limitation of exposure to time-varying electrical, magnetic and electromagnetic fields (up to 300 GHz) (ICNIRP) ( Memento of the original from May 14, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and not yet tested. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 401 kB). In: Horst Heller (Red.): Reports of the radiation protection commission. Book 23: Protection of the population from exposure to electromagnetic fields (up to 300 GHz). Berlin: H. Hoffmann, 1999.

- ↑ International Commission on Non-Ionizing Radiation Protection: Guidelines for Limiting Exposure to Time-varying Electric and Magnetic Fields (1 Hz to 100 kHz) ( Memento of the original from December 31, 2010 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 657 kB). In: Health Physics 99 (2010), No. 6, pp. 818-836.

- ↑ European standard EN 50366 "Method for measuring the electromagnetic fields of household appliances and similar electrical devices with regard to the safety of people in electromagnetic fields", 2008 in adaptation to the essentially technically identical international standard IEC 62233 replaced by the EN 62233 of the same name.

- ↑ a b Federal Department of the Interior, Federal Office of Public Health: EMF fact sheet induction cooker

- ↑ Federal Office for Radiation Protection: Frequently asked questions on the subject of "Electric and magnetic fields in household appliances" ( Memento from January 18, 2012 in the Internet Archive ) in the Internet Archive, accessed on January 9, 2013.

- ↑ FOPH project Induced fields and currents in the body of people who cook as a result of the exposure to magnetic fields in front of induction cookers ( Memento from September 28, 2008 in the Internet Archive ).

- ↑ Frank Rieger : Today without biometrics: Passport "well done". April 7, 2017. Retrieved August 15, 2019 .

- ↑ Induction cooking: IGBTs in resonant converters

- ↑ Kitchen of the Future has Glass-Dome Oven and Automatic Food Mixer, Popular Mechanics Apr 1956, page 88

- ↑ Segmentation produit - sales 2017

- ↑ Induction hobs - share of sales Western Europe 2010 | Statistics. In: Statista. Retrieved August 19, 2016 .